This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

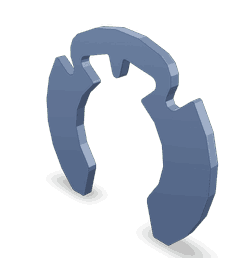

The Cummins 3015525 Retaining Ring is a component designed for use in heavy-duty truck applications. Its purpose is to secure various parts within the truck’s mechanical systems, ensuring they remain in place under operational conditions. The significance of this retaining ring lies in its contribution to the overall reliability and performance of the truck.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by fitting into a groove and exerting a retaining force that keeps parts in position. This function is vital in many mechanical systems, where the secure placement of components is necessary for proper operation 1.

Purpose of the 3015525 Retaining Ring

The 3015525 Retaining Ring plays a specific role in the operation of heavy-duty trucks. It is associated with securing components within the engine or transmission systems, ensuring that parts such as gears, bearings, or sensors remain fixed in their designated positions. This helps maintain the integrity of the mechanical systems and contributes to the truck’s overall performance 2.

Key Features

The 3015525 Retaining Ring is characterized by several key features that enhance its functionality. It is typically made from high-strength materials to withstand the rigors of heavy-duty applications. The design includes a coiled shape that allows it to fit snugly into grooves, providing a secure hold. Additionally, the ring may feature specific dimensions and tolerances to ensure compatibility with various components 3.

Benefits

The use of the 3015525 Retaining Ring offers several benefits. It contributes to improved reliability by ensuring that components remain in place, reducing the risk of mechanical failure. Enhanced performance is another advantage, as secure component placement can lead to more efficient operation of the truck’s systems. Fleet operators may also experience potential cost savings due to reduced maintenance needs and extended component lifespan 4.

Installation Process

Proper installation of the 3015525 Retaining Ring involves several steps. First, the groove where the ring will be placed must be clean and free of debris. Using the appropriate tools, the ring is then expanded and inserted into the groove. Care should be taken to ensure that the ring is seated correctly and exerts the necessary retaining force. Following manufacturer guidelines for installation is recommended to ensure correct placement and function.

Common Issues and Troubleshooting

Common issues with the 3015525 Retaining Ring may include wear, corrosion, or improper installation. Wear can occur over time due to operational stress, while corrosion may result from exposure to harsh environments. Improper installation can lead to insufficient retaining force or component misalignment. Troubleshooting these issues may involve inspecting the ring for damage, cleaning or replacing it as necessary, and ensuring that installation practices are followed correctly.

Maintenance Tips

Regular maintenance of the 3015525 Retaining Ring is important for ensuring longevity and optimal performance. Inspection intervals should be established based on the truck’s operational conditions and manufacturer recommendations. During inspections, the ring should be checked for signs of wear or corrosion, and any issues should be addressed promptly. Proper care, including cleaning and lubrication where applicable, can also contribute to the retaining ring’s effectiveness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the commercial truck industry. The company’s expertise in diesel engines and components, including the 3015525 Retaining Ring, underscores its commitment to providing reliable and high-performance solutions for fleet operators.

Cummins Engine Compatibility with Part 3015525

The Cummins part 3015525, a Retaining Ring, is designed to fit a variety of Cummins engines, ensuring secure and reliable performance. Here is a detailed overview of its compatibility across different engine models:

K19 Series

The K19 engine series, which includes the K19, is compatible with the Retaining Ring part 3015525. This part is crucial for maintaining the integrity of the engine’s components, ensuring smooth operation and longevity.

KTA19GC Series

The KTA19GC engine, along with its variant KTA19GC CM558, is another series that utilizes the Retaining Ring part 3015525. This part is essential for the proper functioning of the engine’s internal mechanisms, providing a secure fit that prevents component displacement.

QSK19 Series

The QSK19 engine series, which includes models such as QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, all require the Retaining Ring part 3015525. This part is integral to the engine’s design, ensuring that all moving parts remain in their designated positions, thereby enhancing the engine’s efficiency and reliability.

QSK45 Series

The QSK45 CM500 engine is also compatible with the Retaining Ring part 3015525. This part plays a critical role in maintaining the structural integrity of the engine, ensuring that all components function as intended without any risk of displacement or failure.

By ensuring that the Retaining Ring part 3015525 is correctly installed, engine performance and durability are significantly enhanced, providing a reliable solution for a range of Cummins engine models.

Role of Part 3015525 Retaining Ring in Engine Systems

The Part 3015525 Retaining Ring is instrumental in maintaining the integrity and functionality of various engine components. It ensures that parts remain securely in place, thereby contributing to the overall efficiency and reliability of the engine system.

In the Cover assembly, the retaining ring holds the cover in position, preventing it from dislodging during operation. This is particularly important in high-vibration environments where the cover could otherwise become misaligned.

For the Front Gear, the retaining ring plays a significant role in keeping the gear properly seated within its housing. This ensures smooth transmission of power and reduces the risk of gear slippage, which could lead to inefficient engine performance.

In the Drive mechanism, the retaining ring secures components that are essential for the transfer of rotational force. By keeping these parts in place, it ensures consistent drive performance and minimizes wear and tear on interconnected components.

The Barring system, which is used for manually rotating the engine, relies on the retaining ring to keep the barring mechanism components aligned. This is vital for maintenance procedures where precise alignment is necessary.

In the Engine Barring Mechanism, the retaining ring ensures that all moving parts remain correctly positioned. This is essential for the smooth operation of the mechanism during engine start-up and shutdown procedures.

For Engine Mounting and Front Engine Mounting, the retaining ring helps in securing the mounting components, ensuring that the engine remains stable within the vehicle’s frame. This stability is crucial for maintaining engine alignment and reducing stress on the mounting points.

In the Front Engine Support and Gear Cover, the retaining ring prevents components from shifting, which is important for maintaining the seal and integrity of the gear cover. This helps in keeping contaminants out and lubricants in, prolonging the life of the gear system.

For the Gear Mounting Cover and Gear Top Level Assembly Cover, the retaining ring ensures that these covers remain firmly in place. This is essential for protecting internal components from external elements and ensuring that the gear assembly functions as intended.

Lastly, in the Support structures of the front engine, the retaining ring plays a role in keeping support components aligned and secure. This contributes to the overall structural integrity of the engine, ensuring that it can withstand operational stresses.

Conclusion

The Cummins 3015525 Retaining Ring is a critical component in heavy-duty truck applications, ensuring the secure placement of various engine and transmission components. Its design and functionality contribute to the reliability, performance, and longevity of the truck’s mechanical systems. Proper installation, regular maintenance, and understanding its role within the engine systems are essential for maximizing the benefits of this Cummins part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.