Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

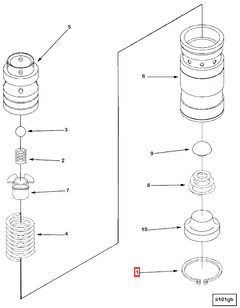

The Cummins 3027988 Retaining Ring is a component designed for use in heavy-duty truck systems. It serves a specific function within the mechanical framework of these vehicles, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and significance is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They are widely employed in various mechanical systems to secure parts in place, ensuring that components remain correctly positioned under operational conditions. Retaining rings function by exerting a radial force that keeps components stationary, thus playing a vital role in the assembly and operation of machinery 1.

Purpose of the 3027988 Retaining Ring

The 3027988 Retaining Ring is specifically designed to secure components within the heavy-duty truck’s engine system. It is associated with the fuel injection system, where it plays a role in maintaining the proper positioning of components critical to the injection process. By securing these parts, the retaining ring contributes to the consistent and reliable operation of the fuel system 2.

Key Features

The design and material characteristics of the 3027988 Retaining Ring are tailored to meet the demands of its application. It features a specific shape and size that allow it to fit securely within the designated area of the engine system. The material properties of the retaining ring, including its hardness and resistance to wear, ensure it can withstand the operational stresses and environmental conditions encountered in heavy-duty truck applications 3.

Benefits of Using the 3027988 Retaining Ring

The advantages of using the 3027988 Retaining Ring include enhanced durability, ease of installation, and reliability in securing components. Its design allows for straightforward installation without the need for complex tools, facilitating maintenance and repair processes. The reliability of the retaining ring in securing components contributes to the overall stability and performance of the truck’s engine system.

Installation Process

Installing the 3027988 Retaining Ring requires careful attention to ensure it is correctly positioned and secured. The process involves using appropriate tools to place the ring within the designated groove or housing. It is important to follow the manufacturer’s guidelines to ensure the ring is installed correctly, which may include specific torque settings or alignment requirements.

Common Issues and Troubleshooting

Typical problems that may arise with retaining rings include displacement or damage, which can affect the securement of components. Troubleshooting these issues may involve inspecting the ring for signs of wear or damage, ensuring it is correctly installed, and addressing any underlying causes of displacement, such as misalignment or excessive wear on mating surfaces.

Maintenance Tips

Regular inspection and maintenance of the 3027988 Retaining Ring are recommended to ensure continued reliable operation. This includes checking for signs of wear or damage during routine maintenance checks and ensuring that all components secured by the retaining ring are functioning correctly. Proper maintenance helps prevent unexpected failures and contributes to the longevity of the engine system.

Replacement Guidelines

Determining when to replace the 3027988 Retaining Ring involves assessing signs of wear or failure. If the ring shows signs of significant wear, damage, or if it no longer securely holds components in place, it should be replaced. Regular inspections during maintenance intervals can help identify when replacement is necessary, ensuring the engine system remains in optimal condition.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its leadership position in the market.

Role of Part 3027988 Retaining Ring in Engine Systems

The 3027988 retaining ring is an essential component in various engine systems, ensuring the secure assembly and operation of multiple parts. Its applications span across several critical areas within the engine, contributing to the overall performance and reliability of the system.

Aftercooler Core and Plumbing

In the aftercooler core and aftercooler plumbing, the retaining ring plays a significant role in maintaining the integrity of connections. It ensures that the plumbing components are securely fastened, preventing leaks and ensuring efficient cooling of the compressed air before it enters the engine. This is vital for maintaining optimal engine temperature and performance.

Cylinder Head Mounting

For cylinder head mounting, the retaining ring is used to secure the cylinder head to the engine block. This ensures a tight seal, which is essential for preventing coolant and oil leaks. A secure cylinder head mounting also contributes to consistent combustion chamber pressure, enhancing engine efficiency and power output.

EBM Performance Parts

In EBM performance parts, such as injectors and tappets, the retaining ring is utilized to hold components in place under high-stress conditions. This is particularly important in performance-enhanced engines where components are subjected to greater forces and temperatures. The retaining ring ensures that these parts remain securely positioned, contributing to the engine’s overall performance and durability.

Injector Plumbing and Tappets

For injector plumbing and tappets, the retaining ring secures fittings and connections, ensuring that fuel delivery is precise and consistent. This is essential for maintaining the engine’s performance, especially in high-performance applications where fuel delivery accuracy can significantly impact engine output and efficiency.

Rocker Housing and Protective Cover

In the rocker housing and protective cover, the retaining ring helps to secure these components in place. This is important for protecting internal engine parts from damage and ensuring that the rocker housing operates smoothly, which is essential for valve train performance and engine reliability.

Turbocharger and Hardware Kit

Within the turbocharger and hardware kit, the retaining ring is used to secure various components, ensuring that the turbocharger operates efficiently. This includes securing turbine and compressor wheel assemblies, as well as ensuring that the turbocharger’s internal components remain aligned and operate within specified tolerances.

Onboard Spares and Kit Spares

In onboard spares and kit spares, the retaining ring is often included to ensure that replacement parts can be securely installed when needed. This is important for maintaining engine uptime and ensuring that repairs can be conducted quickly and effectively.

Fuel Connection and Engine Kit

For fuel connections and within engine kits, the retaining ring ensures that fuel lines and fittings are securely attached. This is vital for preventing fuel leaks and ensuring that the fuel system operates under the correct pressure, which is essential for engine performance and safety.

Hydro Mechanical Step and Top Stop Injector

In hydro mechanical step and top stop injector systems, the retaining ring secures components that control fuel injection timing and pressure. This is crucial for maintaining precise fuel delivery, which directly impacts engine performance, fuel efficiency, and emissions.

Step Tappet Repair Kit

Within the step tappet repair kit, the retaining ring is used to secure repaired or replacement tappets. This ensures that the tappets operate correctly, contributing to the smooth operation of the valve train and overall engine performance.

Conclusion

The 3027988 retaining ring, through its various applications, plays a significant role in ensuring the secure assembly and reliable operation of engine components. Its use across different engine systems underscores its importance in maintaining engine performance, efficiency, and durability.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

Hamid Taghavifar and Aref Mardani, Offroad Vehicle Dynamics Analysis Modelling and Optimization, Springer, 2017.

↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.