This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

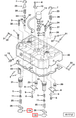

The Cummins 3066964 Retaining Ring is a vital component in the maintenance and operation of commercial trucks. Designed to secure specific parts within the truck’s mechanical systems, this part ensures components remain in place under various operational conditions, contributing to the vehicle’s performance and reliability 1.

Basic Concepts of Retaining Rings

Retaining rings, or circlips, are mechanical fasteners that prevent components from moving along a shaft or within a housing. They create a secure fit, holding parts in place and preventing axial movement. Their simplicity, effectiveness, and ease of installation and removal make them widely used in various mechanical systems 2.

Purpose of the 3066964 Retaining Ring

The Cummins 3066964 Retaining Ring is designed to secure components within the truck’s engine or transmission system. It ensures that parts such as gears, bearings, or other rotating components remain fixed in their intended positions, maintaining precise alignment and operation, which is vital for the efficient functioning of the truck 3.

Key Features

This Cummins part is crafted from high-quality materials to withstand the rigors of commercial truck operation. Its design includes specific dimensions and a spring-like structure that allows it to expand and contract, fitting securely into grooves on shafts or within housings. The material and manufacturing processes used ensure durability, corrosion resistance, and reliable performance under demanding conditions 4.

Benefits

Using the Cummins 3066964 Retaining Ring offers several advantages. It enhances the reliability of the truck’s mechanical systems by securely holding components in place. The design of the ring facilitates easy installation and removal, reducing maintenance time. Additionally, its robust construction contributes to the longevity and consistent performance of the associated components 5.

Installation Process

Installing the Cummins 3066964 Retaining Ring requires careful attention to ensure it is properly seated. The process involves using appropriate tools, such as retaining ring pliers, to expand the ring and place it into the designated groove. It is important to ensure the ring is fully seated and that no part of it protrudes, which could lead to damage or improper function 6.

Troubleshooting Common Issues

Common issues with retaining rings may include improper seating, damage during installation, or wear over time. Diagnosing these issues involves inspecting the ring and the components it secures for signs of misalignment, damage, or excessive wear. Resolving these issues may require replacing the retaining ring or addressing any underlying problems with the secured components 7.

Maintenance Tips

Regular inspection of the Cummins 3066964 Retaining Ring is recommended to ensure its continued effectiveness. This includes checking for signs of wear, corrosion, or damage during routine maintenance checks. Proper lubrication of the components it secures can also contribute to the longevity of the retaining ring and the overall performance of the truck’s mechanical systems 8.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements have made it a preferred choice for commercial vehicle operators worldwide 9.

Compatibility of Cummins Part 3066964

The Cummins part 3066964, a Retaining Ring, is designed to fit into various Cummins engine models. This part plays a role in ensuring the proper functioning of the engine by securing components in place. Below is a detailed breakdown of the compatibility of this retaining ring with different Cummins engines:

6C Series Engines

- 6C8.3

- 6C8.3 G

B Series Engines

- B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

C Series Engines

- C GAS PLUS CM556

- C8.3 G

ISB Series Engines

- ISB CM550

- ISB5.9G CM2180

ISL Series Engines

- ISL9 CM2150 SN

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

M11 Series Engines

- M11 CELECT PLUS

N14 Series Engines

- N14 CELECT PLUS

- N14 MECHANICAL

QSB Series Engines

- QSB5.9 44 CM550

This retaining ring is a critical component in various Cummins engine models, ensuring the proper functioning and longevity of the engine by maintaining the alignment and securing the crankshaft and other rotating parts 10.

Role of Part 3066964 Retaining Ring in Engine Systems

The Part 3066964 Retaining Ring is an essential component in various engine systems, ensuring the secure and efficient operation of multiple parts.

Alternator Drive System

In the Alternator Drive system, the retaining ring maintains the proper alignment and tension of the alternator belt, ensuring consistent power generation and reducing the risk of belt slippage or failure.

Alternator Location and Mounting

For the Alternator Location and Alternator Mounting, the retaining ring secures the alternator in its designated position, which is vital for the alternator’s performance and longevity.

Belt Tensioner Assembly

In the Belt Tensioner assembly, the retaining ring keeps the tensioner mechanism in place. Proper tensioning of the belt is necessary for the efficient transfer of power to various engine components, such as the Water Pump Drive Pulley and the Refrigerant Compressor.

Brake Systems

The C Brake Kit and Campaign Kit utilize the retaining ring to secure components within the braking system, ensuring reliable and consistent braking performance.

Engine Brake Systems

For the Cummins Engine Brake Kit and Engine Brake, the retaining ring maintains the structural integrity of the brake components, allowing for effective engine deceleration and control.

Exhaust Gas Recirculation Valve (EGR) System

In the EGR system, the retaining ring ensures that the valve components remain securely in place, contributing to efficient emissions control and engine performance.

Idler Pulley System

The Idler Pulley system benefits from the retaining ring by maintaining the pulley’s position and ensuring smooth belt operation, which is essential for the proper functioning of the engine’s accessory drives.

Refrigerant Compressor Mounting

In the Refrigerant Compressor Mounting, the retaining ring helps in securing the compressor, ensuring it operates within the correct parameters for efficient cooling system performance.

Water Transfer Connection

Lastly, in the Water Transfer Connection, the retaining ring plays a role in maintaining the integrity of the water transfer system, ensuring consistent coolant flow and engine temperature regulation 11.

Conclusion

The Cummins 3066964 Retaining Ring is a critical component in the maintenance and operation of commercial trucks. Its role in securing various engine and transmission components ensures the efficient and reliable functioning of the vehicle. Regular inspection and proper maintenance of this part are essential for the longevity and performance of the truck’s mechanical systems.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Cummins Inc. Owners Manual for ISF2.8 CM2220. Bulletin Number 2883637, 2023.

↩ -

Cummins Inc. Owners Manual for ISF2.8 CM2220. Bulletin Number 2883637, 2023.

↩ -

Cummins Inc. Owners Manual for ISF2.8 CM2220. Bulletin Number 2883637, 2023.

↩ -

Cummins Inc. Owners Manual for ISF2.8 CM2220. Bulletin Number 2883637, 2023.

↩ -

Cummins Inc. Corporate Overview, 2023.

↩ -

Cummins Inc. Owners Manual for ISF2.8 CM2220. Bulletin Number 2883637, 2023.

↩ -

Cummins Inc. Owners Manual for ISF2.8 CM2220. Bulletin Number 2883637, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.