This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

Barring mechanisms are vital for the maintenance and operation of heavy-duty truck engines. They allow for the manual rotation of the engine crankshaft, which is essential for various maintenance procedures, including engine assembly, disassembly, and inspection. Cummins Inc., a prominent player in the automotive and heavy-duty truck industry, offers the Barring Mechanism Part #3011234. This component is engineered to enhance the efficiency and safety of engine maintenance tasks.

Basic Concepts of Barring Mechanisms

Barring mechanisms are devices used to manually rotate an engine’s crankshaft. This rotation is important for several reasons: it helps dislodge any internal components that may have seized, ensures that all parts are functioning correctly before the engine is started, and aids in the even distribution of lubricants during the initial stages of engine operation. By manually turning the crankshaft, technicians can inspect the engine’s internal components without the risk of damage that might occur if the engine were started under such conditions 1.

Purpose of the 3011234 Barring Mechanism

The 3011234 Barring Mechanism by Cummins is designed to facilitate the safe and efficient rotation of heavy-duty truck engine crankshafts. Its role is crucial in ensuring that engine components are aligned correctly and that there are no obstructions or damages within the engine that could lead to operational issues. This mechanism allows for a controlled environment in which engine maintenance can be performed, reducing the risk of accidental starts and subsequent damage.

Key Features

The 3011234 Barring Mechanism features several key attributes that enhance its functionality and reliability. It is constructed from high-strength materials to withstand the rigors of heavy-duty truck engine maintenance. The design incorporates ergonomic handles for ease of use, ensuring that technicians can apply the necessary force without strain. Additionally, the mechanism is equipped with a locking feature to secure the crankshaft in place, preventing unintended movement during maintenance procedures.

Benefits

Utilizing the 3011234 Barring Mechanism offers several advantages. It contributes to improved engine longevity by ensuring that maintenance tasks are performed correctly and safely. The ease of use and ergonomic design reduce technician fatigue, allowing for more efficient work practices. Furthermore, its reliability in various operating conditions makes it a valuable tool for maintaining heavy-duty truck engines in diverse environments.

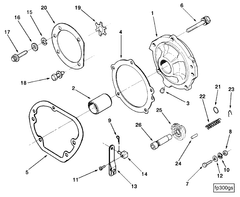

Installation Process

Installing the 3011234 Barring Mechanism involves several steps to ensure proper functionality and safety. Begin by ensuring the engine is in a neutral position and all electrical connections are disconnected to prevent accidental starts. Align the barring mechanism with the crankshaft and secure it in place using the provided locking mechanism. It is advisable to consult the manufacturer’s instructions for specific details and any preparatory steps required.

Troubleshooting and Maintenance

Common issues with the 3011234 Barring Mechanism may include difficulty in securing the crankshaft or resistance during rotation. These issues can often be resolved by ensuring the mechanism is correctly aligned and securely fastened. Regular maintenance, such as cleaning and inspecting for wear, will help ensure the longevity and optimal performance of the mechanism. It is also important to store the mechanism in a dry, secure location when not in use to prevent damage.

Safety Considerations

When installing, using, and maintaining the 3011234 Barring Mechanism, it is important to observe several safety guidelines. Always ensure the engine is disconnected from any power sources before beginning work. Use personal protective equipment, such as gloves and safety glasses, to protect against any potential hazards. Follow the manufacturer’s instructions carefully to avoid misuse of the mechanism, which could lead to injury or damage to the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is evident in its extensive product range, which is designed to meet the demanding requirements of various applications 2.

Cummins Barring Mechanisms in V903 Engines

The Barring Mechanisms, identified by part number 3011234, is a critical component in the V903 engines manufactured by Cummins. This part plays a pivotal role in ensuring the engine’s operational safety by preventing over-speed conditions.

In the V903 engine series, the Barring Mechanisms are designed to monitor the engine’s rotational speed. If the engine’s speed exceeds a predetermined threshold, the mechanism intervenes to prevent potential damage. This is achieved through a series of fail-safes and control systems that work in tandem with the engine’s electronic control unit (ECU).

The Barring Mechanisms are engineered to seamlessly integrate with the V903 engines, providing a reliable safeguard against over-speed scenarios. This integration is crucial for maintaining the engine’s longevity and performance, ensuring that the engine operates within safe parameters under all conditions.

In the broader context of Cummins engine technology, the Barring Mechanisms are a testament to the company’s commitment to safety and reliability. By incorporating such advanced safety features, Cummins ensures that their engines are not only powerful but also dependable in various operational environments 3.

Role of Part 3011234 Barring Mechanism in Engine Systems

When integrating part 3011234 Barring Mechanism into engine systems, it is essential to understand its interactions with various components to ensure optimal performance and reliability.

Interaction with the Barring Mechanism

Part 3011234 is designed to work seamlessly with the barring mechanism, facilitating smooth rotation of the engine during startup and maintenance procedures. This interaction is vital for preventing engine seizure and ensuring that all internal components are properly lubricated before ignition.

Fuel Pump Integration

The barring mechanism, enhanced by part 3011234, indirectly supports the fuel pump’s function. By ensuring the engine rotates freely, it allows the fuel pump to prime the system effectively. This results in a consistent fuel supply to the combustion chambers, enhancing engine performance and reliability.

Mounting Considerations

Proper mounting of the barring mechanism is essential for the effective operation of part 3011234. Secure mounting ensures that the mechanism can apply the necessary force to rotate the engine without causing undue stress on other components. This stability is crucial for maintaining the integrity of the engine block and surrounding parts.

Engine Barring Procedures

During engine barring procedures, part 3011234 plays a significant role in facilitating manual or automated rotation of the engine. This is particularly important in scenarios where the engine needs to be turned over without ignition, such as during maintenance checks or after significant repairs. The smooth operation of the barring mechanism, supported by part 3011234, ensures that the engine components are not damaged during these procedures.

VT903 Short Block Kit Compatibility

When used with the VT903 Short Block Kit, part 3011234 ensures that the short block’s components, including the crankshaft, pistons, and connecting rods, are properly aligned and lubricated before the engine is started. This is essential for the longevity and performance of the short block, as it prevents initial wear and tear that could otherwise occur during the first few startups.

Conclusion

In summary, part 3011234 Barring Mechanism is integral to the smooth operation and maintenance of engine systems, interacting with various components to ensure efficient and reliable performance.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.