This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3035718 Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates the connection between various electrical components, ensuring seamless communication and operation. Its role is significant in maintaining the truck’s electrical integrity and overall performance.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different parts of a vehicle. It consists of insulated wires bundled together, often secured with ties or conduits, and includes connectors that link to various electrical components. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power and signals efficiently, reducing the complexity of individual wire runs and enhancing system reliability 1.

Purpose of the 3035718 Wiring Harness

The 3035718 Wiring Harness is designed to serve specific functions within the electrical system of a truck. It connects critical components such as sensors, actuators, and control modules, ensuring they receive the necessary power and signals to operate correctly. This harness is tailored to meet the demands of commercial truck applications, providing a structured and organized approach to wiring that enhances both performance and safety.

Key Features

The 3035718 Wiring Harness is characterized by several key features that contribute to its effectiveness. Its design incorporates high-quality materials that are resistant to environmental factors such as moisture, heat, and vibration. The harness is engineered with precision to ensure a perfect fit within the truck’s electrical system, reducing the risk of errors during installation. Additionally, it includes unique characteristics such as color-coded wires and pre-assembled connectors, which simplify the installation process and enhance reliability.

Benefits

Utilizing the 3035718 Wiring Harness offers several advantages. It contributes to improved reliability by providing a structured and organized approach to wiring, reducing the likelihood of electrical faults. The harness enhances efficiency by ensuring that electrical components receive the correct voltage and signals, optimizing truck performance. Moreover, it plays a role in safety by minimizing the risk of electrical fires and ensuring that critical systems operate as intended.

Installation Process

Installing the 3035718 Wiring Harness involves several steps to ensure proper integration into the truck’s electrical system. Begin by disconnecting the battery to prevent electrical shocks or short circuits. Identify the location where the harness will be installed, ensuring it is secure and away from moving parts or heat sources. Connect the harness to the appropriate electrical components using the provided connectors, following the manufacturer’s instructions carefully. Once all connections are secure, reattach the battery and test the system to confirm proper operation.

Common Issues and Troubleshooting

Wiring harnesses can encounter issues such as loose connections, damaged wires, or faulty connectors. To address these problems, begin by inspecting the harness for any visible signs of damage or wear. Check all connections to ensure they are secure and free from corrosion. If a wire is damaged, it may need to be repaired or replaced. In cases where a connector is faulty, it should be replaced with a compatible part. Regular inspections and maintenance can help prevent many common issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3035718 Wiring Harness, regular maintenance is recommended. Inspect the harness periodically for signs of wear, damage, or corrosion. Clean the connectors to remove any dirt or debris that could interfere with electrical connections. Ensure that the harness remains securely fastened and is not exposed to excessive heat or moisture. Following these maintenance practices can help prevent issues and ensure reliable operation.

Safety Considerations

When working with the 3035718 Wiring Harness, it is important to follow safety guidelines to prevent accidents and ensure safe operation. Always disconnect the battery before beginning any work on the electrical system to avoid electrical shocks or short circuits. Use appropriate tools and equipment to handle the harness and its components, and wear protective gear such as gloves and safety glasses. Be mindful of the environment in which you are working, ensuring that the area is well-ventilated and free from flammable materials.

Cummins Overview

Cummins is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a history of innovation and excellence in engine and power generation technologies. The company is known for its commitment to quality, reliability, and customer satisfaction, making it a trusted name among commercial truck operators and manufacturers.

Cummins Wiring Harness 3035718 Compatibility with K19, K38, and K50 Engines

The Cummins Wiring Harness part number 3035718 is designed to integrate seamlessly with a range of Cummins engines, including the K19, K38, and K50 models. This wiring harness is a critical component in ensuring the electrical systems of these engines function correctly, facilitating communication between various engine control units and sensors.

For the K19 and K38 engines, the wiring harness 3035718 is engineered to connect essential electrical components, ensuring reliable power distribution and signal transmission. This compatibility is crucial for maintaining optimal engine performance and efficiency. The harness is designed to withstand the operational stresses of these engines, providing a durable and dependable solution for complex electrical needs.

In the case of the K50 engine, the wiring harness 3035718 plays a pivotal role in managing the increased electrical demands of this model. The harness is meticulously crafted to handle the higher power requirements and intricate wiring configurations associated with the K50 engine, ensuring that all electrical systems operate in harmony.

Overall, the Cummins Wiring Harness 3035718 is a versatile and essential component for the K19, K38, and K50 engines, providing a robust and reliable solution for their electrical needs.

Role of Part 3035718 Wiring Harness in Engine Systems

The 3035718 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various subsystems.

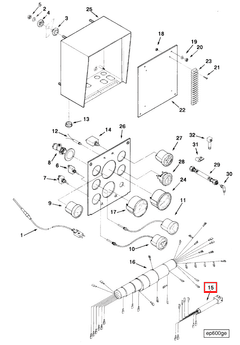

Integration with Key Components

-

Belt Guard: The wiring harness interfaces with the belt guard system, ensuring that electrical signals for monitoring belt tension and wear are accurately transmitted. This integration allows for timely alerts and maintenance actions, enhancing the longevity and reliability of the belt system.

-

Instrument Panel: A primary function of the wiring harness is to connect the instrument panel to the engine’s electrical system. This connection enables the display of vital engine metrics such as temperature, pressure, and RPM, providing the operator with real-time data for informed decision-making.

-

Panel: The harness also plays a role in linking various control panels within the engine system. This includes connectivity for start/stop functions, emergency shutdown procedures, and other operational controls, ensuring that all panel interactions are efficiently managed.

-

Engine Instrument: Within the engine instrument setup, the wiring harness ensures that sensors and gauges are properly powered and that data is accurately relayed. This includes connections for fuel level indicators, oil pressure sensors, and coolant temperature gauges, contributing to the overall monitoring and diagnostic capabilities of the engine system.

Through these connections, the 3035718 Wiring Harness enhances the functionality and reliability of engine systems, supporting efficient operation and maintenance.

Conclusion

The Cummins 3035718 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring seamless communication and operation between various electrical components. Its high-quality design, compatibility with Cummins engines, and integration with key components make it an essential part of maintaining the truck’s electrical integrity and overall performance. Regular maintenance and adherence to safety guidelines are crucial for ensuring the longevity and reliability of this Cummins part.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.