This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

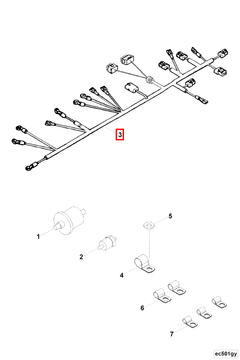

The Cummins 3053029 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a key element in the electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the vehicle, contributing to the overall functionality and performance of the truck.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different parts of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring reliable electrical connections. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow from the power source to the components that require it 1.

Purpose of the 3053029 Wiring Harness

The Cummins 3053029 Wiring Harness is specifically engineered to support the electrical needs of commercial trucks. It integrates with the truck’s engine, transmission, and various electronic control units (ECUs), ensuring that all electrical components receive the necessary power and signals to operate correctly. This harness is designed to withstand the demanding conditions of commercial truck operations, providing a reliable electrical connection that supports the truck’s performance and efficiency.

Key Features

The Cummins 3053029 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear, corrosion, and environmental factors. The harness is also designed with flexibility in mind, allowing it to be routed through the truck’s chassis without compromising its integrity. Additionally, it features unique characteristics such as enhanced insulation and protective coatings that further contribute to its performance and longevity.

Benefits

The use of the Cummins 3053029 Wiring Harness offers several advantages in truck operations. It enhances the reliability of the electrical system by providing secure and consistent connections. This results in improved efficiency, as electrical components can operate without interruptions. Furthermore, the harness contributes to safety by ensuring that all electrical systems function as intended, reducing the risk of electrical failures that could lead to accidents 2.

Installation and Integration

Installing the Cummins 3053029 Wiring Harness requires careful consideration of the truck’s existing electrical system and components. It is important to ensure compatibility with the truck’s model and any aftermarket modifications. The installation process involves routing the harness through the truck’s chassis, connecting it to the power source, and linking it to the various electrical components. Proper installation is crucial to maintain the integrity of the electrical system and ensure optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3053029 Wiring Harness is necessary to ensure its continued reliability and performance. This includes inspecting the harness for signs of wear, corrosion, or damage and addressing any issues promptly. Common problems may include loose connections, damaged wires, or faulty connectors. Troubleshooting involves identifying the source of the issue and making the necessary repairs or replacements to restore the harness’s functionality.

Safety Considerations

When working with the Cummins 3053029 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring that the truck’s battery is disconnected before beginning any work on the harness to prevent electrical shocks. Additionally, proper handling procedures should be followed to avoid damaging the harness or its components. Using the appropriate tools and following manufacturer guidelines can help ensure a safe and effective installation or maintenance process.

Environmental Impact

The production, use, and disposal of the Cummins 3053029 Wiring Harness have environmental considerations. Efforts should be made to minimize waste during manufacturing and to recycle or dispose of the harness responsibly at the end of its life cycle. Cummins Inc. is committed to reducing its environmental footprint through sustainable practices and the development of eco-friendly products 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, known for its innovation, quality, and commitment to customer satisfaction. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial and industrial applications.

Compatibility with Cummins Engines

The Cummins Wiring Harness 3053029 is meticulously designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This wiring harness is engineered to cater to the specific electrical needs of Cummins engines, providing a robust connection that supports the engine’s intricate electronic systems.

V28 Engines

For the V28 engines, the Wiring Harness 3053029 is tailored to manage the complex electrical demands of these high-performance engines. The harness is designed to connect various electrical components, ensuring that power is distributed efficiently and that all systems operate in harmony. This compatibility is crucial for maintaining the engine’s performance and longevity, as it ensures that all electrical pathways are correctly and securely connected.

Group Compatibility

The Wiring Harness 3053029 is not limited to a single engine type but is compatible with a group of Cummins engines. This versatility allows for easier maintenance and repair, as the same wiring harness can be used across multiple engine models, reducing the need for specialized parts and simplifying inventory management for technicians and fleet operators.

Integration and Installation

When integrating the Wiring Harness 3053029 with Cummins engines, it is essential to follow precise installation guidelines to ensure that all connections are secure and that the harness is properly routed to avoid interference with other engine components. The harness is designed to be durable and resistant to environmental factors, ensuring that it can withstand the rigors of continuous use in demanding conditions.

Performance and Reliability

The Wiring Harness 3053029 is a critical component in the overall performance and reliability of Cummins engines. By providing a stable and efficient electrical connection, it helps to prevent issues such as electrical shorts, power loss, and system failures, which can lead to costly downtime and reduced engine efficiency. The harness’s design ensures that it can handle the high electrical loads typical of Cummins engines, contributing to the engine’s overall durability and performance.

Role of Part 3053029 Wiring Harness in Engine Systems

The part 3053029 wiring harness is an integral component in the electrical system of engine setups, facilitating the connection between various electrical components and the power source. It ensures a structured and efficient distribution of electrical power throughout the engine system.

Integration with Accessories

In engine systems, numerous accessories rely on a consistent and reliable electrical supply. The wiring harness plays a significant role in this by connecting accessories such as fuel pumps, sensors, and lighting systems to the main power source. This connection allows these accessories to operate efficiently, ensuring the engine functions smoothly. The harness is designed to handle multiple connections, reducing the risk of electrical faults and improving the overall reliability of the engine system.

Electric Starting System

The electric starting system is another area where the wiring harness is extensively utilized. It connects the starter motor to the battery and other control components, such as the ignition switch and starter relay. This ensures that when the ignition is turned, the starter motor receives the necessary power to crank the engine. The wiring harness is engineered to withstand the high currents involved in starting the engine, ensuring durability and consistent performance. Additionally, it incorporates protective measures such as fuses to safeguard against electrical overloads, further enhancing the system’s reliability.

Conclusion

The Cummins 3053029 Wiring Harness is a critical component in the electrical systems of commercial trucks and Cummins engines. Its robust design, compatibility with various engine models, and role in ensuring reliable electrical connections contribute to the overall performance, efficiency, and safety of the vehicles it serves. Proper installation, maintenance, and adherence to safety practices are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.