This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

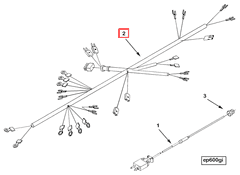

The Cummins 3070995 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals to and from various components within a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in connecting the battery, sensors, control units, and other electrical components, ensuring that they operate correctly and communicate with each other as needed 1.

Purpose of the 3070995 Wiring Harness

The Cummins 3070995 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s engine control module (ECM), sensors, and other critical components. By providing a structured and organized pathway for electrical signals and power, this wiring harness contributes to the efficient operation of the truck’s engine and other systems. Its design allows for seamless integration with the truck’s existing electrical infrastructure, enhancing overall system performance 2.

Key Features

The Cummins 3070995 Wiring Harness is characterized by several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The design of the harness includes organized wire routing and secure connections, which help prevent electrical issues and ensure reliable performance. Additionally, the harness may feature unique attributes such as custom-molded connectors and protective housing, which further contribute to its durability and efficiency 3.

Benefits

The use of the Cummins 3070995 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted reliably and without loss. This reliability enhances the overall performance of the truck’s systems, leading to more consistent operation. Additionally, the harness’s durable construction and design help increase the safety and longevity of the truck’s electrical system, reducing the likelihood of electrical failures and the need for frequent repairs 4.

Installation Considerations

When installing the Cummins 3070995 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include disconnecting the battery to prevent electrical shocks and ensuring that the work area is clean and free of debris. The use of appropriate tools, such as wire strippers and crimping tools, is recommended to ensure secure connections. Careful routing of the wires and adherence to the manufacturer’s instructions will help ensure that the harness is installed correctly and functions as intended.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Cummins 3070995 Wiring Harness, regular maintenance is recommended. This may include inspecting the harness for signs of wear, corrosion, or damage, and cleaning the connections to prevent buildup that could interfere with electrical conductivity. Common issues that may arise include loose connections, damaged wires, or faulty connectors. Troubleshooting methods may involve testing the electrical continuity of the wires, replacing damaged sections, or securing loose connections. Regular checks and timely repairs can help maintain the harness’s efficiency and reliability.

Safety Precautions

When working with the Cummins 3070995 Wiring Harness, it is important to observe electrical safety practices and handling guidelines. This includes disconnecting the battery before beginning any work to prevent electrical shocks. Additionally, using insulated tools and wearing protective gear, such as gloves and safety glasses, can help protect against electrical hazards and physical injuries. Following these safety measures ensures a safe working environment and helps prevent accidents during installation, maintenance, or troubleshooting procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, known for its commitment to quality and innovation. The company’s products are designed to meet the demanding requirements of commercial applications, providing reliable performance and efficiency. Cummins’ dedication to advancing technology and improving product offerings underscores its role as a leader in the industry.

Cummins Wiring Harness 3070995 Compatibility

The Cummins Wiring Harness 3070995 is a component designed to ensure seamless electrical connectivity in various engine models. This wiring harness is engineered to interface with specific engine configurations, ensuring that electrical signals are transmitted efficiently and reliably.

K38 Engine Series

The K38 engine series, known for its robust performance and reliability, is one of the key beneficiaries of the 3070995 wiring harness. This harness is meticulously crafted to fit the intricate electrical architecture of the K38 engines, providing a secure and durable connection that can withstand the rigors of heavy-duty operations.

Cummins Engine Group

Within the broader Cummins engine group, the 3070995 wiring harness is compatible with several engine models that share similar electrical requirements and configurations. This compatibility ensures that the harness can be used across multiple platforms, enhancing its versatility and utility in various applications.

Specific Engine Models

- K38-C15: The 3070995 wiring harness is specifically designed to integrate with the K38-C15 engine, ensuring that all electrical components are properly connected and functioning as intended.

- K38-C13: This engine model also benefits from the 3070995 wiring harness, which is engineered to meet the unique electrical demands of the K38-C13.

- K38-C11: The 3070995 wiring harness is compatible with the K38-C11 engine, providing a reliable solution for maintaining electrical integrity in this model.

Installation and Functionality

When installed, the 3070995 wiring harness ensures that all electrical connections are made with precision, reducing the risk of electrical faults and enhancing overall engine performance. The harness is designed to be easy to install, with clear labeling and secure connections that simplify the process for technicians and mechanics.

Compatibility Considerations

While the 3070995 wiring harness is compatible with several Cummins engine models, it is essential to verify compatibility with specific engine configurations. This ensures that the harness will fit and function correctly, providing the necessary electrical connectivity without issues.

By understanding the compatibility and functionality of the 3070995 wiring harness with the K38 engine series and other Cummins engines, technicians and mechanics can ensure that their equipment remains reliable and efficient.

Role of Part 3070995 Wiring Harness in Engine Systems

The Part 3070995 Wiring Harness is an integral component in the engine wiring system, facilitating the electrical connections necessary for the engine’s operation. It serves as the backbone for transmitting power and signals between various engine components, ensuring seamless communication and functionality.

Integration with Key Engine Components

-

Engine Control Unit (ECU): The wiring harness connects the ECU to various sensors and actuators, allowing the ECU to monitor and control engine performance. This includes data transmission from oxygen sensors, throttle position sensors, and other critical inputs.

-

Ignition System: It provides the necessary connections for the ignition coils, spark plugs, and related components. This ensures precise timing and delivery of sparks to ignite the air-fuel mixture in the cylinders.

-

Fuel Injection System: The harness links the fuel injectors to the ECU, enabling accurate fuel delivery based on engine load and operating conditions. It also connects to the fuel pump and pressure sensor, ensuring consistent fuel supply and pressure.

-

Sensors and Actuators: Various sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and coolant temperature sensor are connected via the wiring harness. These sensors provide vital data to the ECU for optimal engine management. Actuators like the idle air control valve and variable valve timing solenoid also rely on these connections for precise operation.

-

Starting System: Connections to the starter motor and related components are established through the wiring harness, ensuring reliable engine cranking and start-up.

-

Charging System: It includes links to the alternator and battery, facilitating the charging process and maintaining the electrical system’s integrity while the engine is running.

-

Emission Control Systems: Components such as the Exhaust Gas Recirculation (EGR) valve, catalytic converter, and oxygen sensors are interconnected, allowing the ECU to manage emissions effectively and comply with environmental regulations.

-

Accessory Systems: The wiring harness also integrates with accessory systems like the air conditioning compressor, power steering pump, and various engine-driven accessories, ensuring they receive the necessary power and signals for operation.

By providing these essential connections, the Part 3070995 Wiring Harness ensures the engine system operates efficiently, reliably, and in accordance with the manufacturer’s specifications.

Conclusion

The Cummins 3070995 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient and reliable operation of the engine and other systems. Its high-quality construction, key features, and compatibility with various Cummins engine models make it a versatile and essential part for maintaining the electrical integrity of heavy-duty vehicles. Proper installation, maintenance, and adherence to safety precautions are vital for maximizing the performance and longevity of this Cummins part.

-

Reif, Konrad. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Huzij, Robert; Spano, Angelo; Bennett, Sean. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ -

Berns, Karsten; Dressler, Klaus; Fleischmann, Patrick; Grges, Daniel; Kalmar, Ralf; Sauer, Bernd; Stephan, Nicole; Teutsch, Roman; Thul, Martin. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.