This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3171012 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in ensuring that all electrical components receive the necessary power and signals to operate correctly 1.

Purpose of the 3171012 Wiring Harness

The Cummins 3171012 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, to the truck’s power source. This harness plays a role in the efficient distribution of electrical power and signals, ensuring that all connected components function as intended. Its design allows for seamless integration with other systems and components within the truck, enhancing overall vehicle performance.

Key Features

The Cummins 3171012 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear and environmental factors. The harness is designed to withstand the demanding conditions of commercial truck operations, ensuring long-lasting performance. Additionally, it features a compact and organized layout that simplifies installation and maintenance processes.

Benefits of Using the 3171012 Wiring Harness

Utilizing the Cummins 3171012 Wiring Harness in commercial trucks offers several advantages. It contributes to improved efficiency by ensuring that electrical power and signals are reliably transmitted throughout the vehicle. This reliability enhances the overall performance and safety of the truck. Furthermore, the harness’s durable construction and organized design facilitate easier maintenance and troubleshooting, reducing downtime and repair costs 2.

Installation and Integration

When installing the Cummins 3171012 Wiring Harness, it is important to follow manufacturer guidelines to ensure proper integration with the truck’s electrical system. Compatibility with various truck models and systems should be verified to ensure optimal performance. Careful attention to detail during installation helps prevent issues such as loose connections or damage to the harness, which could affect the truck’s electrical functionality.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3171012 Wiring Harness is important to ensure its continued reliable performance. This includes inspecting the harness for signs of wear, corrosion, or damage, and addressing any issues promptly. Troubleshooting common problems, such as intermittent electrical issues or component failures, may involve checking connections, testing electrical continuity, and replacing damaged sections of the harness as needed.

Safety Considerations

When working with the Cummins 3171012 Wiring Harness, observing safety protocols is important to prevent accidents and ensure safe operation. This includes disconnecting the truck’s battery before beginning any work on the electrical system to avoid the risk of electrical shock. Additionally, using appropriate personal protective equipment and following manufacturer guidelines for handling and installation helps maintain a safe working environment.

Cummins Overview

Cummins is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of providing reliable and high-performance engine and component solutions, Cummins has earned a reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry 3.

Cummins Wiring Harness 3171012 Compatibility

The Cummins Wiring Harness part number 3171012 is designed to integrate seamlessly with various Cummins engines, ensuring reliable electrical connectivity and system functionality. This wiring harness is a critical component in the engine’s electrical system, facilitating the transmission of power and signals between different parts of the engine.

QSK19 CM500

The QSK19 CM500 engine, known for its robust performance and efficiency, is one of the engines that benefit from the Cummins Wiring Harness 3171012. This harness is engineered to fit precisely within the engine’s architecture, providing a secure and efficient connection for the electrical components. Its design ensures that the harness can withstand the operational stresses and environmental conditions typical of heavy-duty applications, maintaining its integrity and performance over time.

Grouping of Engines

While the QSK19 CM500 is a notable example, the Cummins Wiring Harness 3171012 is compatible with a range of Cummins engines. This compatibility is due to the standardized design and manufacturing processes employed by Cummins, which ensure that the wiring harness fits well within the engine’s electrical framework. The harness is engineered to meet the specific electrical requirements of each engine model, ensuring optimal performance and reliability.

The integration of the wiring harness into the engine’s system is a critical aspect of its operation. It connects various electrical components, including sensors, actuators, and control units, ensuring that the engine operates smoothly and efficiently. The harness’s design also facilitates easy maintenance and repair, as it allows for straightforward access to the engine’s electrical components.

Role of Part 3171012 Wiring Harness in Engine Systems

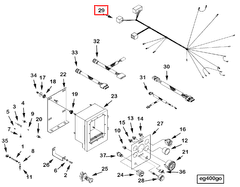

The 3171012 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various engine components.

In the Engine Instrument Panel, the wiring harness ensures that all gauges and indicators receive the necessary electrical signals to display engine performance metrics accurately. It connects sensors that monitor parameters such as temperature, pressure, and RPM to the display units, allowing for real-time data visualization.

Within the Engine Instrument Top-Level Assembly Panel, the wiring harness plays a key role in integrating multiple subsystems. It provides the necessary connections for the panel’s components, including switches, buttons, and displays, ensuring that user inputs are correctly interpreted and executed by the engine control unit (ECU).

For the Instrument Panel Panel, the wiring harness is responsible for routing power and data signals to and from the various instruments. This includes connections to the speedometer, tachometer, fuel gauge, and warning lights, ensuring that all elements function cohesively.

In the broader Panel context, the wiring harness supports the integration of additional components such as climate control systems, audio systems, and navigation units. It ensures that these systems can communicate with the engine’s ECU, allowing for features like engine-dependent climate control adjustments.

Finally, in the Engine Instrument setup, the wiring harness ensures that all engine-related instruments are correctly powered and can transmit data. This includes connections to diagnostic ports, allowing mechanics to retrieve engine performance data and troubleshoot issues efficiently.

Overall, the 3171012 Wiring Harness is essential for maintaining the electrical integrity and functionality of the engine’s instrument systems, ensuring that all components operate in unison for optimal engine performance and driver information.

Conclusion

The Cummins 3171012 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient power and signal distribution. Its robust design, compatibility with various Cummins engines, and role in engine systems highlight its importance in maintaining vehicle performance and safety. Regular maintenance and adherence to safety protocols are essential for the continued reliable operation of this Cummins part.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive (5th ed.). Springer Vieweg.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.