This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

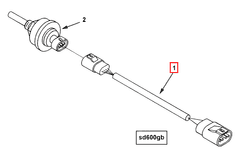

The Cummins 3171090 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. The harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective coverings to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in ensuring that all electrical components receive the necessary power and signals to operate correctly 1.

Purpose of the 3171090 Wiring Harness

This Cummins part is specifically designed to integrate with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control modules, to the truck’s power source. This harness plays a role in the efficient distribution of electrical power and signals, ensuring that all connected components function as intended. Its design allows for seamless integration with other electrical systems, enhancing the truck’s overall electrical performance.

Key Features

The 3171090 Wiring Harness is characterized by its robust design and the use of high-quality materials. It features insulated wires that resist electrical interference and are protected against physical damage. The harness is also designed with durability in mind, capable of withstanding the harsh conditions often encountered in commercial truck operations. Additionally, it includes unique characteristics such as weather-resistant coatings and secure connectors that enhance its performance and longevity.

Benefits

The use of the 3171090 Wiring Harness offers several benefits. It contributes to improved electrical efficiency by ensuring that power and signals are transmitted with minimal loss. The harness reduces the risk of short circuits and other electrical faults, enhancing the reliability of the truck’s electrical system. Its design also supports easier maintenance and troubleshooting, allowing for quicker resolution of any electrical issues that may arise.

Installation Considerations

Proper installation of this part is important for ensuring its effective operation. Installation guidelines recommend disconnecting the truck’s battery to prevent electrical shocks and short circuits. Special tools may be required to secure the harness in place and connect it to the vehicle’s electrical system. Following the manufacturer’s instructions during installation helps ensure that the harness is correctly positioned and connected, contributing to the truck’s electrical system’s overall performance.

Troubleshooting Common Issues

Common issues with the 3171090 Wiring Harness may include electrical faults or connectivity problems. Troubleshooting steps involve checking for loose connections, inspecting the harness for signs of damage, and testing the electrical continuity of the wires. Identifying and resolving these issues promptly helps maintain the harness’s functionality and the truck’s electrical system’s reliability.

Maintenance Tips

Regular maintenance of the 3171090 Wiring Harness is important for ensuring its optimal performance and longevity. Maintenance tips include conducting regular inspections for signs of wear or damage, cleaning the harness to remove dirt and debris, and ensuring that all connections are secure. Adhering to these maintenance practices helps prevent electrical issues and extends the lifespan of the harness.

Safety Precautions

When working with the 3171090 Wiring Harness, observing safety precautions is important. This includes disconnecting the truck’s battery before beginning any work to avoid electrical shocks. It’s also important to avoid contact with live electrical components and to use insulated tools when making connections or adjustments. Following these safety measures helps protect both the technician and the vehicle’s electrical system.

Cummins Overview

Cummins is a well-established manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and efficient solutions for the commercial trucking sector. The company’s product range includes engines, filtration systems, and electrical components, all designed to meet the demanding requirements of commercial truck operations 2.

Cummins Engine Wiring Harness 3171090 Compatibility

The Cummins Wiring Harness part number 3171090 is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connectivity and system functionality. This wiring harness is compatible with the following engines:

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines are part of Cummins’ QSK series, known for their robust performance and efficiency. The 3171090 wiring harness is engineered to fit these engines, providing a comprehensive electrical connection that supports the engine’s control systems, sensors, and other critical components. This ensures that the engine operates smoothly and efficiently, with all electrical systems functioning as intended.

QSK60G

The QSK60G engine is another member of the QSK series, designed for heavy-duty applications. The 3171090 wiring harness is compatible with this engine, offering a reliable and durable electrical connection. This harness is crucial for maintaining the integrity of the engine’s electrical systems, ensuring that all components are properly powered and controlled.

QST30 CM552

The QST30 CM552 engine is part of the QST series, which is known for its versatility and performance in various applications. The 3171090 wiring harness is designed to fit this engine, providing a comprehensive electrical connection that supports the engine’s control systems, sensors, and other critical components. This ensures that the engine operates smoothly and efficiently, with all electrical systems functioning as intended.

By ensuring compatibility with these engines, the 3171090 wiring harness from Cummins provides a reliable and efficient solution for maintaining the electrical integrity of the engine systems.

Role of Part 3171090 Wiring Harness in Engine Systems

The Part 3171090 Wiring Harness is an integral component in the electrical system of engine setups, facilitating the connection between various sensors, switches, and control units. Its primary function is to ensure reliable and efficient transmission of electrical signals and power throughout the engine system.

Integration with the Switch

The wiring harness interfaces with the switch to manage the electrical flow to different engine components. When the switch is activated, the harness transmits the signal to the relevant parts, enabling functions such as ignition, lighting, and accessory operation. This ensures that the engine components receive the necessary power at the correct times, enhancing the overall performance and reliability of the engine system.

Connection to the Coolant Level Sensor

In the coolant system, the wiring harness plays a significant role by connecting the coolant level sensor to the engine control unit (ECU). The sensor monitors the coolant level and sends signals through the harness to the ECU. This data allows the ECU to make real-time adjustments to the engine’s operation, ensuring optimal performance and preventing overheating. The harness ensures a stable and consistent connection, which is essential for accurate sensor readings and effective engine management 3.

Conclusion

The Cummins 3171090 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient distribution of electrical power and signals. Its robust design, compatibility with various Cummins engines, and integration with key engine components highlight its importance in maintaining the electrical integrity and performance of engine systems. Proper installation, regular maintenance, and adherence to safety precautions are essential for maximizing the benefits of this part.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Parikyan, T. Ed. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.