This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

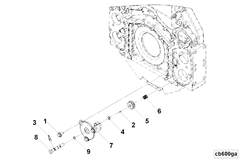

The Cummins 3332325 Barring Drive is a specialized component designed for use in heavy-duty trucks. Its primary function is to facilitate the rotation of the engine without fuel ignition, which is particularly useful during maintenance procedures. This component ensures that the engine can be turned over safely and efficiently, allowing mechanics to perform necessary inspections and repairs without the risk of accidental engine start-up 1.

Basic Concepts of Barring Drives

A barring drive is a tool used to manually rotate an engine’s crankshaft. This rotation is achieved without igniting the fuel, which is essential for maintenance tasks such as inspecting the engine’s internal components, performing valve adjustments, or conducting diagnostic checks. The barring drive connects to the engine’s flywheel or flexplate and is powered by an external source, typically an electric motor. This setup allows for controlled engine rotation, ensuring that all moving parts can be examined and serviced without the engine running under its own power 2.

Purpose of the Cummins 3332325 Barring Drive

The Cummins 3332325 Barring Drive is specifically engineered to integrate seamlessly with Cummins engines found in heavy-duty trucks. It plays a role in facilitating engine rotation during maintenance by providing a safe and controlled method to turn the crankshaft. This is particularly important when performing tasks that require the engine components to be in a specific position or when checking for issues that might not be apparent during normal operation. By using the barring drive, mechanics can ensure that the engine is rotated smoothly and without the risk of damage from unintended ignition 3.

Key Features

The Cummins 3332325 Barring Drive is characterized by several key features that enhance its performance and durability. Its design includes robust construction materials that can withstand the rigors of heavy-duty truck environments. The drive is engineered to fit securely onto the engine’s flywheel or flexplate, ensuring stable and reliable operation. Additionally, it incorporates safety features to prevent accidental engine start-up during use, enhancing the overall safety of maintenance procedures 4.

Benefits of Using the Cummins 3332325 Barring Drive

Utilizing the Cummins 3332325 Barring Drive offers several advantages. It improves engine maintenance capabilities by providing a reliable method to rotate the engine without ignition. This facilitates more thorough inspections and repairs, potentially leading to earlier detection of issues and more effective maintenance. Enhanced safety during maintenance procedures is another significant benefit, as the barring drive reduces the risk of accidental engine start-up. Additionally, by enabling more efficient maintenance, the Cummins 3332325 Barring Drive can contribute to cost savings over time through reduced downtime and extended engine life 5.

Installation and Usage Guidelines

Proper installation and usage of the Cummins 3332325 Barring Drive involve several steps. First, ensure the engine is in a safe condition for maintenance, with all necessary safety precautions in place. Connect the barring drive to the engine’s flywheel or flexplate according to the manufacturer’s instructions. Use an appropriate external power source to rotate the engine, following all safety guidelines to prevent accidental start-up. After use, disconnect the barring drive and store it in a safe location. Regular inspection of the drive for wear or damage is recommended to ensure continued safe and effective operation 6.

Troubleshooting and Maintenance

Common issues with the Cummins 3332325 Barring Drive may include difficulty in fitting the drive to the flywheel or flexplate, uneven engine rotation, or electrical problems with the power source. Troubleshooting steps involve checking the fit and alignment of the drive, ensuring the power source is functioning correctly, and inspecting the drive for any signs of damage or wear. Routine maintenance practices include cleaning the drive after use, checking for any loose or damaged components, and storing it in a dry, secure location to prevent corrosion or damage 7.

Safety Considerations

When using the Cummins 3332325 Barring Drive, several safety guidelines should be observed. Ensure that the engine is completely off and cannot start accidentally during maintenance. Use appropriate personal protective equipment (PPE) such as gloves and safety glasses. Follow all manufacturer instructions for installation and operation to prevent injury or damage. Store the barring drive in a safe place away from children and unauthorized personnel. Regular inspection and maintenance of the drive will help ensure its safe and effective use 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the automotive and heavy-duty truck industry. The company offers a wide range of products designed to meet the needs of various industries, including transportation, construction, agriculture, and power generation. Cummins is known for its commitment to customer satisfaction, technological advancement, and sustainable practices 9.

Compatibility with Cummins Engines

The Barring Drive part 3332325, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is integral to the operation of these engines, ensuring smooth and efficient performance. Below is a detailed description of its compatibility with the specified engines:

K38

The Barring Drive part 3332325 is engineered to integrate perfectly with the K38 engine, providing reliable support and functionality. This compatibility ensures that the K38 engine operates at optimal performance levels.

QSK45 CM500 and QSK60 CM500

Both the QSK45 CM500 and QSK60 CM500 engines are designed to work efficiently with the Barring Drive part 3332325. This part ensures that these engines maintain their high standards of performance and reliability, making it a crucial component for these models.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The Barring Drive part 3332325 is also compatible with the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines. Its design allows for seamless integration, ensuring that these engines function smoothly and efficiently.

QSK60G

The Barring Drive part 3332325 is specifically engineered to fit the QSK60G engine. This compatibility ensures that the engine operates with the precision and reliability expected from Cummins.

QSK78 CM500

The Barring Drive part 3332325 is also compatible with the QSK78 CM500 engine. This part ensures that the engine maintains its high performance and reliability, making it a crucial component for this model.

QSK95 CM2350 K110 and QSK95 CM2350 K113

The Barring Drive part 3332325 is designed to integrate seamlessly with both the QSK95 CM2350 K110 and QSK95 CM2350 K113 engines. This compatibility ensures that these engines operate efficiently and reliably, maintaining their high standards of performance.

Role of Part 3332325 Barring Drive in Engine Systems

Part 3332325 Barring Drive is integral to the operation of various engine systems, ensuring smooth and efficient functionality.

In the drive system, the Barring Drive facilitates the rotation of the crankshaft during engine startup. This action is essential for overcoming the static friction and inertia that the engine components experience when transitioning from a stationary to a moving state. By providing a consistent and controlled rotational force, the Barring Drive helps in evenly distributing the load across the engine’s moving parts, thereby reducing wear and tear.

Within the barring system, the Barring Drive plays a significant role in safeguarding the engine during maintenance or repair procedures. When the engine is not in operation, the Barring Drive allows for the manual rotation of the crankshaft. This feature is particularly useful for inspecting the internal components, such as pistons, connecting rods, and bearings, without the risk of damage from unintended engine startup. Additionally, it aids in the alignment of timing components, ensuring that the engine’s various subsystems operate in harmony once reassembled.

Overall, the Barring Drive is a fundamental component that enhances the reliability and maintainability of engine systems, contributing to their overall performance and longevity 10.

Conclusion

The Cummins 3332325 Barring Drive is a critical component for maintaining and inspecting heavy-duty truck engines. Its robust design, compatibility with various Cummins engines, and safety features make it an essential tool for mechanics. By facilitating safe and controlled engine rotation, this part enhances the efficiency and reliability of maintenance procedures, ultimately contributing to the longevity and performance of the engines it serves.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.