This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

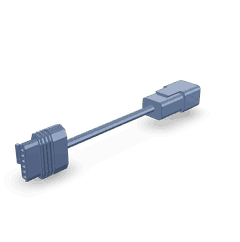

The 3393514 Wiring Harness is a component manufactured by Cummins, designed specifically for use in commercial trucks. This part plays a significant role in the operation of these vehicles by facilitating the electrical connections necessary for various systems to function correctly. Cummins, a well-respected name in the manufacturing of automotive components, ensures that this wiring harness meets high standards of quality and performance 3.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to ensure they are organized and safeguarded from physical damage and environmental factors. In modern vehicles, wiring harnesses are vital as they enable the complex electrical systems to operate efficiently and reliably. They reduce the risk of short circuits and simplify the installation and maintenance processes 1.

Purpose of the 3393514 Wiring Harness

The 3393514 Wiring Harness is designed to play a specific role in the electrical system of a truck. It facilitates communication and power distribution between various components, ensuring that electrical signals and power are transmitted efficiently and reliably. This harness is integral to the operation of the truck’s electrical systems, including lighting, sensors, and control modules 2.

Key Features

The 3393514 Wiring Harness boasts several key features that enhance its performance and durability. Its design is tailored to fit the specific requirements of commercial trucks, ensuring a snug and secure fit. The materials used in its construction are chosen for their durability and resistance to environmental factors such as moisture, heat, and vibration. Additionally, the harness may include unique attributes such as corrosion-resistant connectors and reinforced sections to protect against wear and tear.

Benefits

Using the 3393514 Wiring Harness offers several benefits. It improves the reliability of the truck’s electrical system by ensuring secure and consistent connections. This leads to enhanced efficiency, as electrical signals and power are transmitted with minimal loss. Safety is also improved, as a well-maintained wiring harness reduces the risk of electrical faults that could lead to accidents. Overall, the harness contributes to the truck’s performance by ensuring that all electrical components operate as intended.

Installation Process

Installing the 3393514 Wiring Harness involves several steps to ensure a proper and secure fit. Begin by identifying the correct location for the harness within the truck’s electrical system. Carefully route the wires to avoid sharp edges and moving parts. Connect the harness to the appropriate terminals, ensuring that all connections are secure and tight. Finally, test the harness to confirm that all electrical systems are functioning correctly. Tips for a successful installation include double-checking all connections and ensuring that the harness is protected from physical damage.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, and corrosion. To troubleshoot these problems, start by inspecting the harness for any visible signs of damage or wear. Check all connections to ensure they are secure and free from corrosion. If an issue is identified, repair or replace the affected section as necessary. Regular inspections and maintenance are important to prevent issues from arising and to ensure the longevity of the harness.

Maintenance Tips

To maintain the 3393514 Wiring Harness and ensure its longevity and optimal performance, regular inspections are recommended. Look for signs of wear and tear, such as frayed wires or damaged connectors. Check for corrosion, especially in areas exposed to moisture. Clean the harness as needed to remove dirt and debris that could cause issues. Addressing these problems promptly will help prevent more significant issues down the line and ensure the harness continues to function reliably.

Cummins Overview

Cummins Inc. is a leading manufacturer of automotive components with a rich history of innovation and quality. Founded in 1919, Cummins has built a reputation for producing reliable and high-performance parts for a variety of applications. The company is committed to advancing technology and improving the efficiency and reliability of its products. This commitment is evident in the design and manufacturing of the 3393514 Wiring Harness, which embodies Cummins’ dedication to quality and performance 3.

Cummins Wiring Harness 3393514 Compatibility with K19, K38, and K50 Engines

The Cummins Wiring Harness 3393514 is a critical component designed to ensure seamless electrical connectivity and efficient power distribution across various engine models. This wiring harness is engineered to integrate smoothly with the K19, K38, and K50 engines, providing a reliable electrical pathway that supports the engine’s operational needs.

K19 and K38 Engines

For the K19 and K38 engines, the wiring harness 3393514 is specifically tailored to fit the unique electrical architecture of these models. It ensures that all electrical signals and power are transmitted accurately and efficiently, which is crucial for maintaining optimal engine performance. The harness is designed to withstand the operational stresses of these engines, including high temperatures and vibrations, ensuring durability and longevity.

K50 Engine

The K50 engine, known for its robust design and high performance, also benefits significantly from the use of the Cummins Wiring Harness 3393514. This harness is engineered to handle the complex electrical demands of the K50 engine, providing a stable and reliable connection that supports the engine’s advanced features and capabilities. The harness’s design ensures that all electrical components are properly connected, which is essential for the engine’s efficient operation and longevity.

Common Features Across All Engines

Across the K19, K38, and K50 engines, the wiring harness 3393514 shares several common features that enhance its compatibility and effectiveness. These include:

- Precision Fit: The harness is designed to fit perfectly with the electrical architecture of each engine model, ensuring a secure and reliable connection.

- Durability: Constructed from high-quality materials, the harness is built to withstand the rigors of engine operation, including high temperatures and vibrations.

- Ease of Installation: The harness is designed for straightforward installation, reducing downtime and ensuring that the engine can return to operation quickly.

- Compatibility: The harness is engineered to be compatible with the specific electrical requirements of each engine model, ensuring that all electrical components are properly connected and functioning as intended.

Role of Part 3393514 Wiring Harness in Engine Systems

The 3393514 Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and power distribution among key elements. This harness is meticulously designed to interface with multiple components, facilitating efficient operation and reliability.

Integration with Throttle Extension

The Wiring Harness 3393514 is responsible for connecting the Throttle Extension to the engine’s control unit. This connection allows for precise modulation of the throttle, which is essential for maintaining optimal engine performance. The harness ensures that signals from the throttle position sensor are accurately transmitted to the engine control module (ECM), enabling real-time adjustments to fuel delivery and ignition timing.

Power Distribution to Harness and Wiring

This harness acts as a central conduit for power distribution to other harnesses and wiring within the engine system. It provides the necessary electrical connections to various sensors, actuators, and control modules. By doing so, it ensures that all components receive the appropriate voltage and current, which is vital for their operation.

The harness also incorporates protective measures such as fuses and relays to safeguard against electrical surges and shorts, thereby enhancing the overall reliability of the engine system.

Ensuring System Integrity

Beyond power distribution, the 3393514 Wiring Harness plays a role in maintaining the integrity of the engine system. It is engineered to withstand the harsh environment within the engine compartment, including exposure to heat, vibration, and chemical contaminants. This durability ensures that the electrical connections remain secure and functional over the lifespan of the vehicle.

Conclusion

In summary, the 3393514 Wiring Harness is a fundamental component that enables the efficient and reliable operation of various engine systems by providing essential electrical connections and facilitating communication between components. Its design and construction ensure durability, ease of installation, and compatibility with a range of engine models, making it a critical part of the electrical system in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.