This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

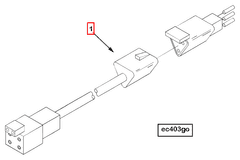

The Cummins 3393515 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, ensuring that power and signals reach their intended destinations efficiently and safely 1.

Purpose of the 3393515 Wiring Harness

The Cummins 3393515 Wiring Harness is designed to integrate with the electrical systems of commercial trucks, specifically those equipped with Cummins engines. It facilitates the connection between the engine’s electrical components and the truck’s power source, enabling the operation of various systems such as the engine control module, sensors, and other electrical devices. This integration ensures that the engine and its associated systems function correctly, contributing to the truck’s overall performance and reliability.

Key Features

The Cummins 3393515 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions often encountered in commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness features durable connectors and terminals that ensure secure and reliable connections. Additionally, its design allows for easy installation and maintenance, enhancing its practicality for use in commercial settings.

Benefits

The use of the Cummins 3393515 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring that electrical systems operate smoothly and reliably. The harness’s robust construction and high-quality materials enhance the reliability of electrical connections, reducing the likelihood of faults or failures. Furthermore, by facilitating the proper functioning of safety-critical systems, the wiring harness plays a role in enhancing the overall safety of truck operations 2.

Installation Considerations

Proper installation of the Cummins 3393515 Wiring Harness is important to ensure its effective operation and longevity. Installation should be carried out by qualified professionals familiar with the specific requirements of commercial truck electrical systems. It may require the use of specialized tools and equipment to ensure that connections are secure and that the harness is properly routed to avoid damage or interference with other components. Following the manufacturer’s guidelines and recommendations during installation is important.

Troubleshooting Common Issues

Common issues with the Cummins 3393515 Wiring Harness may include electrical faults or connectivity problems. These can often be identified through systematic inspection and testing of the harness and its connections. Ensuring that all connections are secure and that there is no visible damage to the wires or connectors is a first step in troubleshooting. In cases where faults are not readily apparent, the use of diagnostic tools may be necessary to pinpoint the issue. Addressing problems promptly can help maintain the reliability and safety of the truck’s electrical systems.

Maintenance Tips

Routine maintenance of the Cummins 3393515 Wiring Harness is important to ensure its longevity and optimal performance. This includes regular inspection of the harness for signs of wear, damage, or corrosion. Cleaning the harness and its connections to remove dirt and debris can also help prevent issues. Additionally, ensuring that all connections remain secure and that the harness is properly routed can contribute to its effective operation. Following the manufacturer’s maintenance recommendations can help extend the life of the wiring harness and ensure the reliable operation of the truck’s electrical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the diverse needs of its customers, from light-duty to heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility with K19, K38, and K50 Engines

The Cummins Wiring Harness 3393515 is designed to integrate seamlessly with a range of Cummins engines, including the K19, K38, and K50 models. This wiring harness is a component in ensuring the electrical systems of these engines function correctly, providing the necessary connectivity for various engine components and systems.

K19 and K38 Engines

For the K19 and K38 engines, the wiring harness 3393515 is engineered to fit precisely, ensuring that all electrical connections are made efficiently. These engines, known for their reliability and performance, benefit from the harness’s robust design, which supports the complex electrical demands of these models. The harness is designed to handle the specific electrical requirements of these engines, ensuring that power is distributed correctly and efficiently.

K50 Engine

The K50 engine, part of Cummins’ lineup of high-performance engines, also integrates the wiring harness 3393515 effectively. This engine, known for its power and efficiency, requires a wiring harness that can manage its advanced electrical systems. The harness is designed to fit the K50’s architecture, ensuring that all electrical components are connected properly, which is crucial for the engine’s optimal performance.

Grouping the Engines

When considering the K19, K38, and K50 engines together, it is evident that the wiring harness 3393515 is designed to be versatile and adaptable. This harness is engineered to fit a range of Cummins engines, ensuring that it can meet the specific electrical needs of each model. The commonality in design allows for easier maintenance and repair, as the same wiring harness can be used across different engine models, simplifying the process for technicians and operators.

Role of Part 3393515 Wiring Harness in Engine Systems

The 3393515 Wiring Harness is an integral component in the electrical system of engine assemblies, facilitating the seamless transmission of electrical signals and power between various engine components. This harness is meticulously designed to interface with multiple systems, ensuring efficient operation and communication.

Integration with Key Components

-

Harness and Throttle Extension: The 3393515 Wiring Harness connects to the throttle extension, allowing for precise control of the engine’s throttle system. This connection ensures that the throttle responds accurately to driver inputs, maintaining optimal engine performance and fuel efficiency.

-

Wiring Connections: The harness is responsible for linking various wiring systems throughout the engine. It provides a robust and reliable pathway for electrical signals, reducing the risk of interference and ensuring consistent performance. This includes connections to sensors, actuators, and control modules, which rely on accurate and timely data transmission.

-

Sensor Integration: By interfacing with numerous sensors such as the oxygen sensor, mass airflow sensor, and crankshaft position sensor, the 3393515 Wiring Harness plays a key role in monitoring engine conditions. These sensors provide vital data to the engine control unit (ECU), allowing for real-time adjustments to fuel delivery, ignition timing, and other critical parameters.

-

Actuator Control: The harness also facilitates communication with various actuators, including the fuel injectors, idle air control valve, and variable valve timing solenoids. This ensures that the engine operates smoothly under varying conditions, enhancing both performance and reliability.

-

Grounding and Shielding: Effective grounding and shielding are essential for the proper function of the 3393515 Wiring Harness. It ensures that electrical signals are not distorted by external electromagnetic interference, maintaining the integrity of the data transmitted throughout the engine system.

Conclusion

In summary, the 3393515 Wiring Harness is a fundamental element in the electrical architecture of engine systems, enabling the efficient and reliable operation of numerous components. Its role in facilitating communication and power distribution underscores its importance in modern engine design.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.