This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

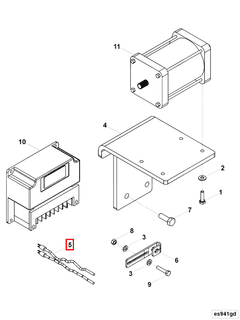

The Cummins 3395526 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals to and from different components within a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness plays a role in connecting the battery, sensors, control units, and other electrical components, ensuring they operate correctly and in unison 1.

Purpose of the 3395526 Wiring Harness

The Cummins 3395526 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s engine control module (ECM), sensors, and other critical components. By providing a structured and organized pathway for electrical signals and power, this wiring harness contributes to the efficient operation of the truck’s engine and other systems, enhancing overall performance and reliability.

Key Features

The 3395526 Wiring Harness is characterized by its robust design and high-quality materials, which are selected to withstand the demanding conditions of commercial truck operations. It features durable connectors and terminals that ensure secure and reliable connections. The harness is also designed with flexibility in mind, allowing it to accommodate the movements and vibrations inherent in truck operations without compromising its integrity.

Benefits

The use of the Cummins 3395526 Wiring Harness in commercial trucks offers several advantages. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted without loss or interference. This results in more reliable operation of the truck’s systems. Additionally, the harness’s design enhances safety by reducing the risk of electrical faults and ensuring that all connections are secure and properly insulated.

Installation Considerations

Proper installation of the 3395526 Wiring Harness is vital to ensure its effectiveness and longevity. Installation should be carried out by qualified professionals who are familiar with the specific requirements of commercial truck electrical systems. It may require the use of specialized tools and should be performed in accordance with the manufacturer’s guidelines to ensure all connections are secure and the harness is properly routed to avoid damage 2.

Maintenance and Troubleshooting

Regular maintenance of the 3395526 Wiring Harness is important to ensure its continued performance and reliability. This includes inspecting the harness for signs of wear, damage, or corrosion, and ensuring all connections are secure. Basic troubleshooting techniques can be employed to identify and address common issues, such as loose connections or damaged wires, to prevent more serious problems from developing.

Compatibility and Applications

The Cummins 3395526 Wiring Harness is designed for use in specific models and series of commercial trucks. Its compatibility ensures that it can be effectively integrated into the electrical systems of these vehicles, providing reliable performance and enhancing the functionality of the truck’s systems.

Safety Precautions

When working with the 3395526 Wiring Harness, it is important to observe safety precautions to prevent accidents and ensure personal safety. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools to avoid electrical shocks, and ensuring that all work is performed in a well-ventilated area to prevent the accumulation of hazardous fumes.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is committed to providing reliable and efficient solutions that meet the needs of its customers. The company’s products are known for their quality, performance, and durability, making them a preferred choice for commercial truck operators worldwide 3.

Cummins Wiring Harness Part 3395526 Compatibility

The Cummins Wiring Harness part 3395526 is designed to integrate seamlessly with a range of engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to fit specific engine configurations, providing a critical link between various electrical components and the engine control unit (ECU).

G5.9 Engines

For the G5.9 engine series, the wiring harness part 3395526 is meticulously crafted to match the electrical architecture of these engines. This ensures that all sensors, actuators, and other electrical components are properly connected, facilitating efficient engine operation and diagnostics. The harness is designed to withstand the operational stresses of the G5.9 engine, maintaining integrity and performance over time.

G8.3 Engines

Similarly, the G8.3 engine series benefits from the precise design of the Cummins Wiring Harness part 3395526. This harness is tailored to the unique electrical requirements of the G8.3 engines, ensuring that all electrical pathways are correctly established. The harness’s robust construction and precise routing help in minimizing electrical interference and ensuring stable power delivery to critical engine components.

Compatibility and Installation

The compatibility of the wiring harness with both G5.9 and G8.3 engines is achieved through a combination of standardized connectors and custom routing paths. This ensures that the harness can be easily installed and replaced without the need for extensive modifications to the engine or its surrounding components. The harness is designed to integrate with other electrical components in the engine bay, providing a cohesive and reliable electrical system.

By ensuring a perfect fit and reliable performance, the Cummins Wiring Harness part 3395526 plays a role in the overall functionality and longevity of the G5.9 and G8.3 engines.

Role of Part 3395526 Wiring Harness in Engine Systems

The 3395526 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution between various electronic components.

Integration with the Governor

In engine systems equipped with a governor, the 3395526 Wiring Harness plays a role in ensuring the governor operates efficiently. The governor, which regulates the engine’s speed, relies on precise electrical signals to function correctly. The wiring harness provides the necessary connections for the governor to receive power and communicate with other engine control units (ECUs). This ensures that the governor can accurately monitor and adjust the engine speed in response to varying load conditions.

Connection to Electronic Components

The 3395526 Wiring Harness is also essential for integrating various electronic components within the engine system. It serves as the backbone for the electrical network, allowing for the transmission of data and power between sensors, actuators, and the ECU.

For instance, sensors that monitor parameters such as temperature, pressure, and fuel levels are connected via the wiring harness to the ECU. This enables the ECU to make real-time adjustments to the engine’s operation based on the data received. Similarly, actuators that control functions like fuel injection and ignition timing are powered and controlled through the wiring harness, ensuring that the engine operates smoothly and efficiently.

Enhanced System Reliability

By centralizing the electrical connections, the 3395526 Wiring Harness enhances the reliability and maintainability of the engine system. It reduces the number of individual wires that would otherwise be required, minimizing the risk of loose connections or shorts. This centralized approach also simplifies troubleshooting, as technicians can more easily trace electrical issues back to the harness, rather than sifting through a web of individual wires.

Support for Advanced Engine Features

In modern engine systems that incorporate advanced features such as electronic throttle control, variable valve timing, and emissions control systems, the 3395526 Wiring Harness is indispensable. It provides the necessary infrastructure to support these features, ensuring that all components can interact seamlessly. This integration allows for more precise control over engine performance, leading to improved efficiency, reduced emissions, and enhanced drivability.

Conclusion

The Cummins 3395526 Wiring Harness is a critical component in the electrical systems of commercial trucks and engines, ensuring efficient and reliable operation. Its robust design, compatibility with specific engine models, and role in integrating electronic components make it indispensable for modern engine systems. Proper installation, maintenance, and adherence to safety precautions are essential to maximize the benefits of this Cummins part.

-

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

An Introduction to Engine Testing and Development, Richard D. Atkins, SAE International, 2009

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.