This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3396090 Wiring Harness Assembly is a component designed for use in commercial trucks, manufactured by Cummins Inc. This assembly plays a significant role in the electrical system of trucks, facilitating the connection between various electrical components and systems. Cummins, a well-established manufacturer in the automotive industry, is known for its expertise in diesel engine manufacturing and commitment to innovation and quality 2.

Basic Concepts of Wiring Harness Assembly

A wiring harness assembly is a collection of wires, terminals, and connectors that run throughout a vehicle’s electrical system. It serves as the central nervous system for the truck, allowing for the transmission of electrical signals and power between different components. The assembly typically includes insulated wires, connectors, and protective housings. Proper wiring is vital for the efficient and safe operation of truck systems, ensuring that electrical components function correctly and reliably 1.

Purpose of the 3396090 Wiring Harness Assembly

The 3396090 Wiring Harness Assembly is specifically designed to facilitate the connection between various electrical components and systems within a truck. It plays a role in ensuring that electrical signals and power are distributed efficiently throughout the vehicle. This assembly helps in maintaining the integrity of the electrical system by providing a structured and organized method for wiring.

Key Features

The 3396090 Wiring Harness Assembly features a robust design that includes high-quality materials and precise engineering. It is constructed using durable materials that can withstand the harsh conditions often encountered in commercial trucking. The assembly includes features such as corrosion-resistant connectors, high-temperature insulation, and a compact design that allows for easy installation and maintenance. These characteristics enhance its performance and durability, making it suitable for demanding applications.

Benefits

Using the 3396090 Wiring Harness Assembly offers several benefits. It contributes to improved electrical efficiency by ensuring that connections are secure and reliable. The assembly reduces the risk of short circuits and electrical failures, which can be common in poorly wired systems. Additionally, its durable construction enhances its longevity, even in harsh operating conditions, providing truck operators with a reliable and long-lasting solution for their electrical needs.

Installation Considerations

When installing the 3396090 Wiring Harness Assembly, it is important to consider compatibility with various truck models and systems. Following manufacturer recommendations ensures that the assembly is installed correctly and functions as intended. Proper installation involves careful routing of wires, secure connection of terminals, and protection of the assembly from physical damage and environmental factors.

Troubleshooting Common Issues

Common issues with wiring harness assemblies can include loose connections, damaged wires, and corrosion on terminals. Regular inspections and maintenance can help identify and address these problems before they lead to more significant issues. Troubleshooting steps may involve checking for secure connections, inspecting wires for damage, and cleaning terminals to remove corrosion. Preventive maintenance is key to ensuring the longevity and optimal performance of the assembly.

Maintenance Tips

To ensure the longevity and optimal performance of the 3396090 Wiring Harness Assembly, it is important to keep it clean, dry, and free from physical damage. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. Keeping the assembly protected from moisture and contaminants can prevent corrosion and extend its lifespan. Additionally, avoiding sharp edges and excessive bending of wires can help maintain the integrity of the assembly.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive industry. The company’s commitment to excellence is evident in its wide range of products, including the 3396090 Wiring Harness Assembly, which is designed to meet the demanding requirements of commercial trucking applications 2.

Integration with Cummins Engines

G8.3 Series

The G8.3 series engines benefit from the precise wiring configurations provided by the 3396090 harness. This part is specifically tailored to manage the electrical demands of these engines, ensuring that all sensors, actuators, and control modules are properly connected. The harness is designed to withstand the operational stresses of the engine, providing a durable and long-lasting solution.

Other Cummins Engines

While the primary focus is on the G8.3 series, the 3396090 wiring harness is also compatible with other Cummins engines. This versatility allows for a standardized approach to engine wiring, simplifying maintenance and repair processes. The harness is engineered to meet the stringent electrical requirements of Cummins engines, ensuring optimal performance and reliability.

Compatibility and Installation

The installation of the 3396090 wiring harness is straightforward, thanks to its modular design. Technicians can easily route and secure the harness within the engine compartment, ensuring that all connections are secure and properly insulated. This design facilitates efficient troubleshooting and maintenance, reducing downtime and improving overall engine efficiency.

Quality and Performance

Cummins is renowned for its high-quality components, and the 3396090 wiring harness is no exception. Manufactured to meet Cummins’ rigorous standards, this harness provides a reliable electrical pathway, minimizing the risk of failures and ensuring consistent engine performance. The harness is designed to handle the electrical loads typical of Cummins engines, providing a robust solution for both light-duty and heavy-duty applications.

Role of 3396090 Wiring Harness Assembly in Engine Systems

The 3396090 Wiring Harness Assembly is an integral component in the electrical system of an engine, facilitating the connection between various electrical components and the ignition system.

Integration with the Electrical System

In the electrical system, the 3396090 Wiring Harness Assembly serves as the backbone for transmitting electrical power and signals. It connects the battery to the starter motor, ensuring that the engine can be started reliably. Additionally, it links the alternator to the battery, allowing for the recharging of the battery while the engine is running. The harness also provides power to essential components such as the fuel pump, ensuring a consistent fuel supply to the engine.

Interaction with the Ignition System

Within the ignition system, the 3396090 Wiring Harness Assembly plays a significant role by connecting the ignition switch to the ignition coil. This connection is vital for the ignition process, as it allows the ignition switch to send a signal to the ignition coil, which then generates the high voltage needed to create a spark at the spark plugs. This spark is essential for igniting the air-fuel mixture in the combustion chamber, thereby powering the engine.

Furthermore, the wiring harness assembly interfaces with the engine control unit (ECU), providing it with the necessary power and data connections. This allows the ECU to monitor and control various engine parameters, such as fuel injection timing and ignition timing, ensuring optimal engine performance and efficiency.

Conclusion

The 3396090 Wiring Harness Assembly is a fundamental component that ensures the seamless operation of the electrical and ignition systems within an engine, contributing to reliable and efficient engine performance. Its robust design, compatibility with various Cummins engines, and ease of installation make it a valuable asset for commercial trucking applications.

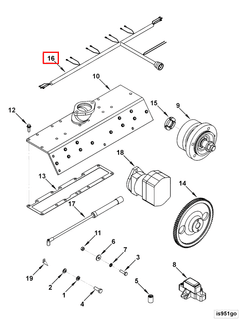

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.