This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3424703 Locking Ring is a specialized component designed for use in heavy-duty truck applications. Its purpose is to secure various parts within the truck’s mechanical systems, ensuring they remain in place under operational stress. This locking ring is significant due to its role in maintaining the integrity and performance of critical truck components.

Basic Concepts of Locking Rings

Locking rings, also known as retaining rings or circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing 1. They contribute to the stability and reliability of assemblies by securing parts in place, which is vital for the proper functioning of mechanical systems. Locking rings come in various designs, including internal and external types, each suited to specific applications based on the requirements of the assembly.

Purpose of the Cummins 3424703 Locking Ring

The Cummins 3424703 Locking Ring is specifically designed to play a role in securing components within the truck’s engine and transmission systems. It ensures that parts remain fixed in their intended positions, which is crucial for the efficient operation of these systems. By preventing movement and misalignment, the locking ring contributes to the overall reliability and performance of the truck.

Key Features

The Cummins 3424703 Locking Ring is characterized by its robust design and material composition. Made from high-strength steel, it offers durability and resistance to wear and corrosion. Its shape is engineered to provide a secure fit within the designated grooves or housings, ensuring that it effectively holds components in place. Unique design elements may include specific dimensions and surface treatments to enhance its performance in heavy-duty applications.

Benefits

Utilizing the Cummins 3424703 Locking Ring offers several advantages. Its high-strength material composition ensures enhanced durability, making it suitable for the demanding conditions of heavy-duty truck operations 2. The reliable performance of the locking ring contributes to the overall efficiency and longevity of the truck’s mechanical systems. Additionally, its design allows for easy installation and removal, facilitating maintenance procedures.

Installation Process

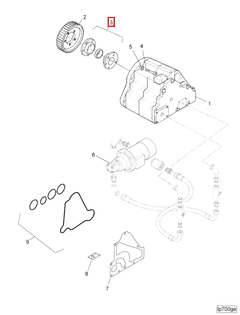

Proper installation of the Cummins 3424703 Locking Ring is crucial for its effective function. The process involves selecting the correct size and type of locking ring for the application, ensuring the groove or housing is clean and free of debris, and using appropriate tools to install the ring securely in place. Careful attention to these steps ensures that the locking ring performs its intended role without issues.

Common Issues and Troubleshooting

Typical problems associated with the Cummins 3424703 Locking Ring may include wear, corrosion, or improper installation. Wear can occur due to continuous use and exposure to operational stresses, while corrosion may result from environmental factors. Improper installation can lead to inadequate securing of components. Troubleshooting these issues involves inspecting the locking ring for signs of damage or misalignment, cleaning or replacing it as necessary, and ensuring correct installation techniques are followed.

Maintenance Tips

Regular maintenance of the Cummins 3424703 Locking Ring is important to prolong its service life and ensure optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the locking ring and its housing to remove any debris or corrosion, and verifying that it remains securely in place. Adhering to recommended inspection intervals and maintenance procedures helps maintain the integrity of the truck’s mechanical systems.

Role in Engine and Transmission Systems

The Cummins 3424703 Locking Ring interacts within engine and transmission systems by securing components that are critical to their operation. Its role in preventing movement and misalignment contributes to the efficiency and reliability of these systems. By ensuring that parts remain fixed in their intended positions, the locking ring plays a part in the overall performance and durability of the truck 3.

Compatibility with Cummins Engines

This part is designed to fit a variety of Cummins engines, ensuring that components remain securely fastened and preventing any movement that could lead to mechanical failure. It is compatible with engines such as the QSV81G, QSV91G, QSV91-G4 CM558/CM700 V102, QSW/QSV82, QSW27, QSW36, and QSW73.

Role in Engine Systems

The Locking Ring (Part 3424703) is integral to the secure assembly and operation of various engine components. Its application ensures the stability and efficiency of the engine system by maintaining the proper alignment and connection of parts.

In the lubricating oil assembly pump, the Locking Ring is used to secure the pump housing to the engine block, ensuring that the pump operates within the designed parameters without any misalignment that could lead to inefficiencies or failures. This secure fit is essential for the consistent delivery of lubricating oil to critical engine components, reducing wear and enhancing performance.

For the lubricating oil mounting pump, the Locking Ring plays a similar role. It ensures that the pump is correctly mounted and aligned, which is vital for the effective circulation of lubricating oil throughout the engine. Proper alignment prevents leaks and ensures that oil reaches all necessary components, maintaining optimal engine health.

In the lubricating oil pump, the Locking Ring is employed to secure the pump’s internal components, such as gears or rotors, ensuring they remain in the correct position during operation. This stability is crucial for the pump’s efficiency in delivering oil under pressure to various engine parts.

When considering the broader pump system, the Locking Ring is used to secure the pump’s casing to the engine or its mounting bracket. This ensures that the pump can operate under varying conditions without shifting, which could lead to performance issues or damage.

In the context of the lubricating oil system as a whole, the Locking Ring contributes to the integrity of the system by ensuring that all components are securely fastened. This is particularly important in high-stress environments where vibrations and thermal expansion can cause parts to loosen over time.

For the water pump, the Locking Ring is used to secure the pump housing and impeller, ensuring that the water flow through the engine’s cooling system is consistent and reliable. This is essential for maintaining the engine’s operating temperature within safe limits, preventing overheating and potential damage.

Overall, the Locking Ring (Part 3424703) is a fundamental component in ensuring the secure and efficient operation of various engine systems, from lubricating oil pumps to water pumps, by maintaining the proper alignment and connection of critical parts.

Conclusion

The Cummins 3424703 Locking Ring is a critical component in heavy-duty truck applications, ensuring the secure assembly and operation of various engine and transmission components. Its robust design, high-strength material, and ease of installation contribute to the overall reliability and performance of the truck. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring the longevity and efficiency of the truck’s mechanical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.