This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3606683 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. Its role is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and improving the efficiency of the electrical system. Within a vehicle, the wiring harness plays a role in connecting the battery to other electrical components, such as lights, sensors, and the engine control unit, ensuring that electricity is distributed as needed 1.

Purpose of the 36066683 Wiring Harness

The Cummins 3606683 Wiring Harness is specifically engineered to integrate with the electrical systems of commercial trucks. It plays a role in connecting various electrical components, ensuring that they receive the necessary power and signals to operate correctly. This harness is designed to work in conjunction with other systems within the truck, such as the engine control module and various sensors, to facilitate smooth and efficient operation 2.

Key Features

The 3606683 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the demanding conditions often encountered in commercial truck operations. Key features include its durable construction, which enhances its resistance to wear and environmental factors, and its precise engineering, which ensures reliable connections and efficient electrical transmission 3.

Benefits

The advantages of using the 3606683 Wiring Harness include improved efficiency in electrical transmission, enhanced reliability due to its robust construction, and ease of installation compared to traditional wiring methods. Its design allows for a more organized and protected electrical system, reducing the likelihood of issues such as short circuits and electrical failures.

Installation Process

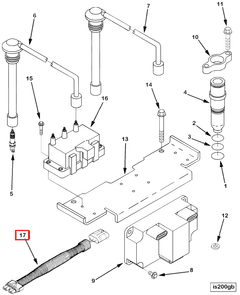

Installing the 3606683 Wiring Harness requires careful attention to detail to ensure proper integration with the truck’s electrical system. The process involves identifying the correct location for the harness, securing it in place, and connecting it to the appropriate electrical components. Best practices include following the manufacturer’s guidelines, using the correct tools, and ensuring all connections are secure and properly insulated. Common pitfalls to avoid include improper routing of the harness, which can lead to damage or reduced efficiency, and insufficient securing, which may result in movement and potential disconnection.

Maintenance and Care

To ensure the longevity and optimal performance of the 3606683 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris that may accumulate, and checking connections for tightness and integrity. Proper maintenance helps prevent issues such as electrical failures and ensures the harness continues to function effectively.

Troubleshooting Common Issues

Frequent problems associated with wiring harnesses can include loose connections, damage to the wires or connectors, and issues with electrical transmission. Practical solutions for addressing these issues involve inspecting the harness for any visible signs of damage, ensuring all connections are secure, and testing the electrical system for proper function. In cases where damage is detected, repair or replacement of the affected components may be necessary.

Safety Considerations

When working with the 3606683 Wiring Harness, it is important to observe safety protocols to prevent accidents and ensure compliance with industry standards. This includes wearing appropriate personal protective equipment, ensuring the vehicle’s electrical system is de-energized before beginning work, and following manufacturer guidelines for installation and maintenance. Adhering to these safety considerations helps protect both the technician and the vehicle from potential hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as filtration and emission solutions, demonstrating its broad expertise in the automotive and heavy-duty truck industries.

Role of Part 3606683 Wiring Harness in Engine Systems

The 3606683 wiring harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various subsystems.

Integration with Accessories

In engine systems, the wiring harness connects to a variety of accessories, ensuring they receive the necessary power and signals to operate efficiently. These accessories may include fuel pumps, sensors, and emission control devices. The harness routes electrical signals from the engine control unit (ECU) to these accessories, allowing for precise control and monitoring of their functions.

Wiring System Coordination

The wiring harness acts as the central nervous system for the engine’s electrical components. It organizes and protects the myriad of wires that transmit power and data throughout the engine system. This includes connections to the battery, starter motor, and various sensors distributed across the engine. By consolidating these wires into a single, organized unit, the harness reduces the risk of electrical shorts and enhances the reliability of the engine’s electrical system.

Ignition System Support

A key function of the wiring harness is its role in the ignition system. It provides the necessary connections for the ignition coil, spark plugs, and ignition control module. The harness ensures that the ignition system receives a consistent and regulated power supply, which is essential for the precise timing of spark delivery to the combustion chambers. This results in efficient fuel combustion and optimal engine performance.

System-Wide Electrical Management

Beyond individual components, the wiring harness plays a pivotal role in managing the overall electrical load of the engine system. It helps in distributing power evenly across all connected components, preventing overloads and ensuring that each part of the engine operates within its designed parameters. This balanced distribution is vital for the longevity and performance of the engine’s electrical components.

Conclusion

In summary, the 3606683 wiring harness is a fundamental element in the engine’s electrical system, ensuring that all components—from accessories to the ignition system—are powered and controlled effectively. Its role in maintaining the integrity and efficiency of the engine’s electrical network cannot be overstated.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.