This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3628049 Wiring Harness is a specialized component designed for use in commercial trucks. It serves a vital role in the electrical system, facilitating the connection between various electrical components and the truck’s power source. This harness ensures that electrical signals and power are efficiently distributed throughout the vehicle, contributing to the overall functionality and performance of the truck.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different parts of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in connecting the battery, sensors, control units, and other electrical components, enabling them to communicate and operate in unison 1.

Purpose of the 3628049 Wiring Harness

The 3628049 Wiring Harness is specifically engineered to integrate into the electrical system of commercial trucks. It facilitates the connection between the truck’s power source and various electrical components, such as sensors, control modules, and lighting systems. This harness ensures that electrical signals and power are accurately and reliably transmitted, supporting the truck’s operational functions and enhancing its performance.

Key Features

The 3628049 Wiring Harness is characterized by several key features that enhance its functionality and durability. It is designed with high-quality materials to withstand the demanding conditions of commercial truck operations. The harness includes robust connectors and terminals that ensure secure and stable connections. Additionally, it is constructed with durable insulation to protect the wires from abrasion, moisture, and other environmental factors. The design of the harness also takes into account the specific routing and spacing requirements of commercial trucks, ensuring a neat and organized installation.

Benefits of Using the 3628049 Wiring Harness

Utilizing the 3628049 Wiring Harness offers several advantages in truck operations. It contributes to improved reliability by ensuring consistent and secure electrical connections. The harness enhances efficiency by optimizing the distribution of electrical power and signals throughout the truck. Furthermore, it plays a role in safety by reducing the risk of electrical faults and malfunctions, which can lead to hazardous situations on the road 2.

Installation Process

Installing the 3628049 Wiring Harness requires careful attention to detail and adherence to safety protocols. The process involves identifying the correct routing paths for the harness within the truck, securing it in place with appropriate fasteners, and connecting it to the relevant electrical components. Tools such as wire strippers, crimping tools, and electrical tape may be required. It is important to follow the manufacturer’s instructions and take necessary safety precautions, such as disconnecting the battery before beginning the installation.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, it is important to conduct a thorough inspection of the harness and its connections. Checking for signs of wear, corrosion, or physical damage can help identify potential issues. Using a multimeter to test the continuity of the wires and the integrity of the connections can also aid in diagnosing problems. Repairing or replacing damaged sections of the harness may be necessary to restore proper functionality.

Maintenance Tips

Regular maintenance of the 3628049 Wiring Harness is important to ensure its longevity and optimal performance. This includes inspecting the harness for signs of wear or damage, cleaning the connectors to remove any corrosion or debris, and ensuring that all connections are secure and tight. It is also beneficial to protect the harness from physical damage by securing it properly and avoiding sharp edges or moving parts that could cause abrasion.

Safety Considerations

When working with electrical components like the 3628049 Wiring Harness, it is important to observe safety protocols to prevent accidents and injuries. This includes disconnecting the battery before beginning any work on the electrical system, wearing appropriate personal protective equipment, and ensuring that all tools and equipment are in good condition. It is also important to be aware of the potential risks associated with electrical work, such as electric shock or short circuits, and to take necessary precautions to mitigate these risks 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company offers a wide range of products and services, including diesel and natural gas engines, as well as aftermarket parts and services, catering to various industries and applications.

Cummins Wiring Harness 3628049 Compatibility with K19 Engines

The Cummins Wiring Harness part number 3628049 is designed to integrate seamlessly with various engine models, including the K19 series. This wiring harness is a critical component that ensures the electrical systems of these engines function correctly.

K19 Engine Series

The K19 engine series, known for its robust performance and reliability, benefits significantly from the precise engineering of the Cummins Wiring Harness 3628049. This part is engineered to provide a secure and efficient electrical connection, ensuring that all components of the engine receive the necessary power and signals.

The harness is meticulously designed to fit the specific electrical architecture of the K19 engines, allowing for easy installation and minimal downtime during maintenance or replacement. Its compatibility with the K19 series ensures that the engine operates at peak efficiency, with all electrical systems working in harmony.

Installation and Integration

When installing the Cummins Wiring Harness 3628049 with the K19 engines, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. The harness is designed to connect with the engine’s electrical components, including sensors, actuators, and control modules, providing a reliable pathway for electrical signals.

The harness’s durability and resistance to environmental factors make it an ideal choice for use in various conditions, ensuring that the K19 engines maintain their performance over time. The precise routing and secure connections of the harness contribute to the overall reliability and longevity of the engine’s electrical system.

Grouping of Engines

The Cummins Wiring Harness 3628049 is not limited to the K19 series alone. It is also compatible with other engine models that share similar electrical architectures. This versatility allows for a broader application across different engine types, providing a standardized solution for various engine models.

By grouping engines with compatible electrical systems, the harness ensures that the installation process is streamlined, reducing the need for custom modifications and enhancing the ease of maintenance. This approach not only saves time but also ensures that the engines operate efficiently and reliably.

Engine Performance and Reliability

The integration of the Cummins Wiring Harness 3628049 with the K19 engines significantly impacts the overall performance and reliability of the engine. The harness’s design ensures that all electrical components receive the necessary power and signals, allowing the engine to operate smoothly and efficiently.

The reliability of the harness contributes to the longevity of the engine, reducing the likelihood of electrical failures and ensuring that the engine maintains its performance over time. This reliability is crucial for applications where downtime is not an option, such as in heavy-duty industrial or commercial settings.

Role of Part 3628049 Wiring Harness in Engine Systems

The part 3628049 wiring harness is integral to the efficient operation of various engine systems, particularly when paired with components such as the fuel pressure transducer.

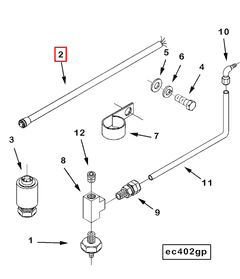

Integration with Fuel Pressure Transducer

The wiring harness facilitates the connection between the fuel pressure transducer and the engine control unit (ECU). This connection is essential for the accurate monitoring of fuel pressure within the system. The transducer sends real-time data to the ECU, allowing for precise fuel delivery adjustments. The wiring harness ensures that this data transmission is reliable and uninterrupted, which is vital for maintaining optimal engine performance and fuel efficiency.

Enhanced System Functionality

By providing a structured and organized pathway for electrical signals, the wiring harness reduces the risk of signal interference and ensures that the fuel pressure transducer operates within specified parameters. This results in more consistent fuel pressure readings, which are critical for the ECU to make informed decisions regarding fuel injection timing and quantity.

Support for Diagnostic Processes

The wiring harness also plays a role in simplifying diagnostic processes. When issues arise within the fuel system, the integrity of the wiring harness allows for accurate readings from the transducer, aiding in the identification of potential problems. This can significantly reduce diagnostic time and enhance the overall maintenance efficiency of the engine system.

Conclusion

The Cummins 3628049 Wiring Harness is a critical component in the electrical systems of commercial trucks and engines, ensuring reliable and efficient operation. Its compatibility with various engine models, including the K19 series, highlights its versatility and importance in maintaining engine performance and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.