This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3635803 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital element in the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to its overall operation and performance.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays, which are bundled together to transmit electrical power and signals within a vehicle. It simplifies the installation process and reduces the risk of electrical faults by organizing the wiring into a single, manageable unit. Within a vehicle’s electrical system, the wiring harness plays a role in connecting the battery, sensors, control units, and other electrical components, ensuring they operate in unison 1.

Purpose of the 3635803 Wiring Harness

The Cummins 3635803 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s engine control module (ECM), sensors, and other critical components. By providing a structured pathway for electrical signals and power, this wiring harness contributes to the efficient operation of the truck’s engine and ancillary systems. Its design allows for seamless integration with the truck’s existing electrical architecture, enhancing overall system performance 2.

Key Features

The Cummins 3635803 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to the harsh conditions often encountered in commercial truck operations. The harness features a compact design that allows for easy installation and maintenance. Additionally, it incorporates protective measures such as shielding and insulation to safeguard against electrical interference and environmental factors, ensuring reliable performance over time 3.

Benefits

The use of the Cummins 3635803 Wiring Harness in commercial trucks offers several advantages. It enhances the efficiency of electrical signal transmission, contributing to improved engine performance and fuel efficiency. The harness’s reliable design reduces the likelihood of electrical faults, leading to increased safety and reliability in truck operations. Furthermore, its durability ensures long-term performance, minimizing the need for frequent replacements and maintenance.

Installation and Integration

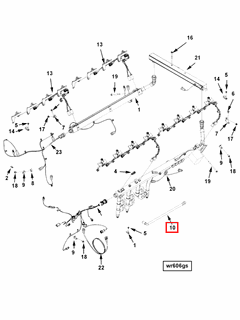

Installing the Cummins 3635803 Wiring Harness requires careful consideration of the truck’s electrical system and compatibility with existing components. It is important to ensure that the harness is correctly aligned with the truck’s wiring diagram and that all connections are secure. Prior to installation, it is advisable to disconnect the battery to prevent electrical shocks or short circuits. Following the manufacturer’s guidelines for installation will help ensure that the harness is integrated seamlessly into the truck’s electrical system.

Troubleshooting Common Issues

Common issues with the Cummins 3635803 Wiring Harness may include electrical faults or connectivity problems. To address these issues, it is important to conduct a thorough inspection of the harness and its connections. Checking for loose or corroded connections, damaged wires, or signs of wear can help identify potential problems. In cases where electrical faults persist, consulting the truck’s wiring diagram and using diagnostic tools can aid in pinpointing the source of the issue.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3635803 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and cleaning the harness to remove any dirt or debris that may accumulate over time. Additionally, protecting the harness from physical damage and environmental factors can help prevent premature failure.

Safety Considerations

When working with the Cummins 3635803 Wiring Harness, it is important to observe safety practices to prevent accidents and injuries. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools to avoid electrical shocks, and wearing appropriate personal protective equipment. Additionally, following the manufacturer’s guidelines for installation, maintenance, and troubleshooting will help ensure safe and effective use of the wiring harness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and commercial truck industries. The company’s commitment to innovation, quality, and customer satisfaction has made it a preferred choice for commercial vehicle operators worldwide.

Compatibility with Engine Models

The Cummins Wiring Harness part number 3635803 is designed to integrate seamlessly with a variety of Cummins engine models, ensuring reliable electrical connectivity and optimal performance. This wiring harness is compatible with the following engines:

- QSK60 CM850 MCRS

- QSK78 CM500

These engines, while differing in specific configurations and power outputs, share a commonality in their electrical systems, making the 3635803 wiring harness a versatile component suitable for both models. The harness is engineered to handle the electrical demands of these engines, providing a robust and dependable connection for various electrical components within the engine system.

Role of Part 3635803 Wiring Harness in Engine Systems

The 3635803 Wiring Harness is an integral component in the orchestration of various engine systems, facilitating seamless communication and power distribution among key elements.

Primarily, the harness connects the Electronic Control Module (ECM) to the Engine Control Module (ECM), ensuring that the engine’s operational parameters are consistently monitored and adjusted. This connection allows the ECM to receive real-time data from sensors distributed throughout the engine, enabling it to make precise adjustments to fuel injection, ignition timing, and other critical functions.

Furthermore, the wiring harness interfaces with various modules within the engine system, such as the transmission control module and the anti-lock braking system module. This integration ensures that the engine operates in harmony with other vehicle systems, optimizing performance and safety.

Additionally, the harness plays a significant role in powering ancillary components such as the fuel pump, starter motor, and various sensors. By providing a reliable electrical pathway, it ensures that these components receive the necessary voltage and current to function correctly.

Conclusion

In summary, the 3635803 Wiring Harness is a linchpin in the engine’s electrical architecture, enabling efficient communication, precise control, and reliable power distribution across a multitude of components. Its robust design, compatibility with various Cummins engine models, and integral role in engine systems make it a critical component for the efficient and safe operation of commercial trucks.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.