This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

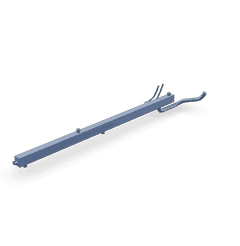

The Cummins 3637070 Wiring Harness is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the electrical connections necessary for the operation of various truck systems. This part plays a role in ensuring that electrical signals are transmitted efficiently and reliably throughout the vehicle, contributing to the overall functionality and performance of the truck 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals to different components within a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness serves as the backbone, enabling communication between the engine, sensors, lights, and other electrical components 2.

Purpose of the 3637070 Wiring Harness

This Cummins part is specifically designed to integrate with the electrical systems of commercial trucks. It plays a role in connecting various components, such as sensors, lights, and the engine control module (ECM), ensuring that they receive the necessary power and signals to function correctly. This harness is engineered to withstand the demanding conditions of commercial truck operations, providing a reliable electrical connection that supports the truck’s performance and efficiency 3.

Key Features

The 3637070 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear and environmental factors. The harness is designed to be compact yet comprehensive, accommodating the complex electrical requirements of modern commercial trucks. Additionally, it features protective sheathing to safeguard the wires from physical damage and corrosion 4.

Benefits

The use of the 3637070 Wiring Harness offers several benefits in truck operations. It contributes to improved efficiency by ensuring that electrical connections are secure and reliable. This reliability enhances the overall performance of the truck, reducing the likelihood of electrical failures. Furthermore, the harness supports safety by maintaining consistent electrical signals, which is crucial for the operation of safety-critical systems.

Installation Process

Installing the 3637070 Wiring Harness involves several steps to ensure proper integration with the truck’s electrical system. The process begins with identifying the correct location for the harness within the truck. Next, the existing wiring is disconnected, and the new harness is routed through the designated pathways. Connectors are then attached to the appropriate components, and the harness is secured in place. Tools required for installation may include wire cutters, crimping tools, and electrical tape.

Troubleshooting Common Issues

Common issues with the 3637070 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To address these problems, it is important to conduct a thorough inspection of the harness. Loose connections can be re-secured, damaged wires may need to be repaired or replaced, and faulty connectors should be inspected for proper seating and function. Regular checks can help identify and resolve issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3637070 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and protecting the harness from environmental factors such as moisture and extreme temperatures. Additionally, keeping the harness clean and free from debris can help prevent corrosion and maintain its integrity.

Safety Considerations

When working with the 3637070 Wiring Harness, it is important to observe safety precautions. This includes ensuring that the truck’s battery is disconnected before beginning any work to prevent electrical shocks. Additionally, using appropriate personal protective equipment (PPE), such as gloves and safety glasses, can help protect against injuries. Proper handling of the harness and its components is also crucial to avoid damage during installation or maintenance.

Cummins Overview

Cummins is a well-established company with a strong reputation in the automotive and heavy-duty truck industries. Founded in 1919, Cummins has a history of innovation and quality, providing reliable engines and components for a wide range of applications. The company is known for its commitment to excellence, continuously striving to improve its products and services to meet the evolving needs of its customers.

Cummins Engine Wiring Harness 3637070

The Cummins Wiring Harness part number 3637070 is a critical component in the electrical system of various Cummins engines. This wiring harness is designed to ensure reliable and efficient electrical connections within the engine’s system, facilitating the transfer of power and signals necessary for the engine’s operation.

Application in Cummins Engines

The Wiring Harness 3637070 is compatible with several Cummins engine models, including:

- QSK60 CM500: This harness is integral to the QSK60 CM500 engine, providing the necessary electrical pathways for various engine functions. It ensures that all electrical components are properly connected, allowing for seamless communication and operation.

Importance of the Wiring Harness

The wiring harness is essential for maintaining the integrity of the engine’s electrical system. It connects various sensors, actuators, and control units, ensuring that the engine can operate efficiently and safely. Proper installation and maintenance of this harness are crucial for preventing electrical faults and ensuring the longevity of the engine.

Installation and Maintenance

When installing the Wiring Harness 3637070, it is important to follow the manufacturer’s guidelines to ensure that all connections are secure and correctly routed. Regular inspections should be conducted to check for any signs of wear, corrosion, or damage, which could compromise the harness’s performance. Any issues should be addressed promptly to prevent potential engine malfunctions.

Role of Part 3637070 Wiring Harness in Engine Systems

The Part 3637070 Wiring Harness is an integral component in the electrical architecture of engine systems. It serves as the backbone for the electrical connectivity required for seamless operation of various engine components.

Integration with Accessories

The wiring harness facilitates the connection of various accessories to the engine system. These accessories may include lighting systems, cooling fans, and other auxiliary devices that require electrical power. The harness ensures that these components receive the necessary voltage and current, enabling them to function efficiently and reliably.

Electrical System Coordination

In the broader electrical system, the Part 3637070 Wiring Harness acts as a conduit for power distribution. It links the battery to the starter motor, ignition system, and other electrical components, ensuring that each part receives the appropriate electrical supply. This coordinated power distribution is essential for the synchronized operation of the engine’s electrical systems.

Connection to Electronic Control Module (ECM) Kit

The wiring harness plays a significant role in interfacing with the Electronic Control Module (ECM) kit. The ECM is the brain of the engine, controlling various functions such as fuel injection, ignition timing, and emissions. The harness provides the necessary connections for data transmission and power supply to the ECM, allowing it to monitor and adjust engine performance in real-time.

Harnessing Engine Monitoring Wiring

Engine monitoring is a key aspect of modern engine systems, and the Part 3637070 Wiring Harness is central to this function. It connects various sensors—such as temperature sensors, pressure sensors, and oxygen sensors—to the ECM. These sensors provide vital data on engine conditions, allowing the ECM to make informed decisions to optimize performance and efficiency. The harness ensures that this data is accurately and reliably transmitted, contributing to effective engine monitoring and diagnostics.

Conclusion

In summary, the Part 3637070 Wiring Harness is a fundamental component that ensures the electrical integrity and functionality of engine systems. Its role in connecting and powering various components—from accessories to the ECM and engine monitoring systems—underscores its importance in the overall operation of the engine.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.