This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3637361 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, ensuring that power and signals reach their intended destinations efficiently and safely 1.

Role of the 3637361 Wiring Harness in Truck Operation

The Cummins 3637361 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects various components such as sensors, lights, and control modules, enabling them to communicate and operate in unison. This harness plays a role in the truck’s operation by ensuring that all electrical components receive the necessary power and signals to function correctly. Its integration with other systems enhances the truck’s overall efficiency, reliability, and safety 2.

Key Features

The Cummins 3637361 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typically encountered in commercial truck operations, including exposure to vibrations, temperature extremes, and moisture. Unique characteristics of this wiring harness include its precise engineering to fit specific truck models and its ability to support high current loads, ensuring reliable performance under demanding conditions 3.

Benefits of Using the 3637361 Wiring Harness

Utilizing the Cummins 3637361 Wiring Harness offers several advantages. It contributes to improved efficiency by ensuring that electrical power is distributed effectively throughout the truck. The harness enhances reliability by providing a durable and secure connection between components. Additionally, it plays a role in safety by reducing the risk of electrical faults and ensuring that all systems operate as intended, which is vital for the safe operation of commercial trucks.

Installation Considerations

Proper installation of the Cummins 3637361 Wiring Harness is crucial for its effective operation. It is important to follow manufacturer guidelines to ensure that the harness is correctly positioned and securely connected to all components. Special attention should be given to protecting the harness from physical damage and ensuring that all connections are tight and corrosion-free. Any prerequisites, such as the need for specific tools or preparatory steps, should be adhered to for a successful installation.

Troubleshooting Common Issues

Common problems associated with wiring harnesses can include loose connections, damaged wires, or corrosion at connection points. To address these issues, it is advisable to conduct regular inspections of the harness and its connections. If problems are identified, steps such as tightening connections, repairing or replacing damaged wires, and cleaning or applying corrosion-resistant coatings can be taken to resolve these issues and restore the harness’s functionality.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3637361 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear, damage, or corrosion. Keeping the harness clean and dry, and protecting it from physical damage, can help prevent issues. Additionally, ensuring that all connections remain tight and secure will contribute to the reliable operation of the truck’s electrical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a key player in the commercial truck industry, providing innovative and reliable solutions that meet the demanding requirements of commercial vehicle operators worldwide.

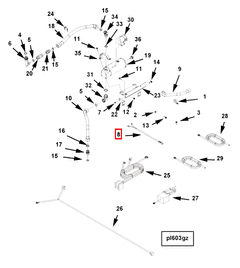

Cummins Wiring Harness 3637361 in QSK78 CM500 Engines

The Cummins Wiring Harness part number 3637361 is a critical component in the QSK78 CM500 engines. This wiring harness is meticulously designed to ensure seamless electrical connectivity across various engine systems. It plays a pivotal role in maintaining the operational integrity of the engine by facilitating the transmission of electrical signals between different parts of the engine.

In the QSK78 CM500 engines, the wiring harness is integral to the engine’s electronic control unit (ECU) and other vital systems. It ensures that all electrical components, such as sensors, actuators, and control modules, are properly interconnected. This allows for efficient communication and control, which is essential for the engine’s performance and reliability.

The harness is engineered to withstand the harsh operating conditions typical of heavy-duty engines. It is constructed with high-quality materials that provide durability and resistance to environmental factors such as heat, vibration, and moisture. This ensures that the harness maintains its functionality over the engine’s lifespan.

Proper installation of the wiring harness is crucial. It requires precise routing and secure connections to prevent electrical faults and ensure optimal performance. Technicians must follow specific guidelines to ensure that the harness is correctly integrated into the engine’s electrical architecture.

The Cummins Wiring Harness 3637361 is a testament to the company’s commitment to quality and reliability. It is designed to meet the stringent demands of modern heavy-duty engines, ensuring that the QSK78 CM500 engines operate at peak efficiency.

Role of Part 3637361 Wiring Harness in Engine Systems

The Part 3637361 Wiring Harness is an integral component in the electrical architecture of engine systems, specifically designed to interface with the primer and engine lubricating systems.

Integration with Primer System

In the primer system, the wiring harness facilitates the electrical connections necessary for the operation of the primer solenoid. This solenoid is responsible for injecting fuel into the intake manifold to aid in engine starting, especially in cold conditions. The wiring harness ensures a reliable and consistent power supply to the primer solenoid, which is essential for its precise operation. It also connects to the engine control unit (ECU), allowing for the monitoring and control of the priming process. This integration ensures that the primer system operates efficiently, contributing to smoother engine starts.

Connection to Engine Lubricating System

For the engine lubricating system, the wiring harness plays a significant role in powering and controlling the oil pressure sensor and the oil pump (if electrically driven). The oil pressure sensor provides real-time data on oil pressure levels to the ECU, which uses this information to adjust engine parameters for optimal performance and protection. The wiring harness ensures that the sensor receives a stable power supply and that the data transmission to the ECU is accurate and uninterrupted.

In engines with electrically driven oil pumps, the wiring harness is responsible for delivering power to the pump and facilitating communication between the pump and the ECU. This allows for dynamic adjustment of oil flow based on engine load and operating conditions, ensuring that the engine receives adequate lubrication under all circumstances.

Overall Functionality

The Part 3637361 Wiring Harness, therefore, acts as the nervous system for these critical engine components, ensuring that they receive the necessary power and signals to function correctly. Its role in maintaining the electrical integrity and communication between the primer and lubricating systems is fundamental to the overall performance and reliability of the engine.

Conclusion

The Cummins 3637361 Wiring Harness is a critical component in the electrical systems of commercial trucks and heavy-duty engines. Its robust design, high-quality materials, and precise engineering ensure reliable performance under demanding conditions. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part, contributing to the overall efficiency, reliability, and safety of the vehicle.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.