This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3640314 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals to various components within a vehicle. It typically includes insulated wires bundled together, connectors for joining different parts of the harness, and terminals for connecting to electrical components. The harness plays a role in organizing and protecting the wires, reducing the risk of short circuits and ensuring reliable electrical connections 1.

Purpose of the 3640314 Wiring Harness

The Cummins 3640314 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects key components such as sensors, control modules, and actuators to the truck’s power supply. This harness plays a role in ensuring that these components receive the necessary electrical signals and power to function correctly. Its design allows for efficient signal transmission and power distribution, contributing to the truck’s operational efficiency and reliability.

Key Features

The Cummins 3640314 Wiring Harness is characterized by several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is designed to be compact yet robust, allowing it to fit within the confined spaces of a truck’s engine compartment while withstanding the vibrations and harsh conditions typical of commercial truck operations. Additionally, it includes specialized connectors and terminals that ensure secure and reliable connections.

Benefits of Using the 3640314 Wiring Harness

Utilizing the Cummins 3640314 Wiring Harness offers several advantages for truck operations. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted reliably and without loss. This reliability enhances the overall performance of the truck’s electrical systems, leading to more consistent operation of critical components. Furthermore, the harness’s durable construction and resistance to environmental factors contribute to its longevity, reducing the need for frequent replacements and maintenance 2.

Installation Process

Installing the Cummins 3640314 Wiring Harness requires careful attention to detail to ensure proper function and safety. The process involves identifying the correct routing paths for the harness within the truck’s engine compartment, securing it in place using appropriate fasteners, and connecting it to the relevant electrical components and power sources. It is important to follow the manufacturer’s guidelines for installation to ensure that all connections are secure and that the harness is properly protected from physical damage and environmental factors.

Common Issues and Troubleshooting

Typical problems that may arise with the Cummins 3640314 Wiring Harness include loose connections, damaged wires, and corrosion at connector points. These issues can lead to intermittent electrical problems or complete failure of connected components. Troubleshooting involves inspecting the harness for visible signs of damage, ensuring that all connections are secure, and testing the electrical continuity of the wires. In cases where damage is detected, repairs or replacements may be necessary to restore proper function.

Maintenance Tips

Regular maintenance of the Cummins 3640314 Wiring Harness is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage, ensuring that all connections remain secure, and protecting the harness from physical damage and environmental factors. Cleaning the harness and its connectors can also help prevent the buildup of dirt and corrosion, which can interfere with electrical connections 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines, powertrain solutions, and aftermarket parts designed to meet the demanding requirements of commercial truck operations.

Wiring Harness 3640314 Compatibility with Cummins Engines

The Wiring Harness part number 3640314, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This part is crucial for ensuring proper electrical connectivity and functionality within the engine system. Below is a detailed description of how this wiring harness fits with the specified engines.

QSK50 CM2150 MCRS and QSK50 CM2350 K108

The Wiring Harness 3640314 is compatible with the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in various industrial applications. The harness is engineered to interface with the specific electrical architecture of these engines, ensuring that all necessary connections are made without modification. This compatibility is critical for maintaining the engine’s operational integrity and performance.

QST30 CM2350 T101

Similarly, the Wiring Harness 3640314 is also designed to fit the QST30 CM2350 T101 engine. This engine, like the QSK50 series, benefits from the precise electrical connections provided by this harness. The harness is tailored to meet the electrical requirements of the QST30 engine, ensuring that all components are properly powered and controlled. This compatibility is essential for the engine’s efficient operation and longevity.

Grouping of Engines

The Wiring Harness 3640314 is compatible with the following engines:

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QST30 CM2350 T101

These engines, while part of different series, share a commonality in their electrical systems, allowing the harness to be universally applied across these models. This compatibility ensures that technicians and operators can confidently use the same wiring harness across multiple engine types, simplifying maintenance and repair processes.

Role of Part 3640314 Wiring Harness in Engine Systems

The Part 3640314 Wiring Harness is an integral component in the electrical system of engine setups, ensuring seamless communication and power distribution among various engine components.

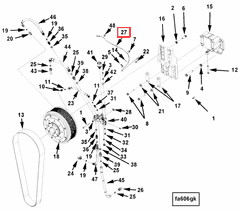

Integration with the Drive System

In the drive system, the Wiring Harness facilitates the transmission of electrical signals from the engine control unit (ECU) to the drive components. This ensures that the drive operates in sync with the engine’s performance parameters, optimizing power delivery and efficiency.

Connection to the Fan

For the fan, the Wiring Harness plays a key role in regulating its operation. It connects the fan to the engine’s thermal management system, allowing the fan to respond accurately to temperature changes. This ensures that the engine maintains optimal operating temperatures, preventing overheating and enhancing longevity.

Interaction with the Manifold

In relation to the manifold, the Wiring Harness is responsible for transmitting sensor data from the manifold to the ECU. This data is vital for the ECU to make real-time adjustments to fuel injection and air-fuel ratio, thereby improving engine performance and fuel efficiency.

Role in Lubricating Oil Access

Finally, the Wiring Harness is essential in the lubricating oil access system. It connects sensors that monitor oil pressure and temperature, providing the ECU with necessary data to ensure the engine is adequately lubricated. This is fundamental in preventing engine wear and ensuring smooth operation.

Conclusion

In summary, the Part 3640314 Wiring Harness is a fundamental component in the electrical architecture of engine systems, enabling efficient and reliable operation of various engine components.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.