This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3642490 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to its overall operation and performance.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in enabling communication and power distribution among the engine, lights, sensors, and other electrical components 1.

Purpose of the 3642490 Wiring Harness

The Cummins 3642490 Wiring Harness is specifically engineered to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s battery, engine control module (ECM), sensors, and various electrical accessories. By providing a structured and organized pathway for electrical signals and power, this wiring harness contributes to the efficient operation of the truck’s electrical systems, enhancing both performance and reliability.

Key Features

The 3642490 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable, corrosion-resistant materials to withstand the harsh conditions often encountered in commercial trucking. The harness features precise wiring and connector placements to ensure optimal performance and reliability. Additionally, it is designed with flexibility in mind, allowing for easy installation and integration with the truck’s existing electrical systems.

Benefits

The use of the Cummins 3642490 Wiring Harness offers several advantages. It enhances the efficiency of electrical signal transmission and power distribution within the truck, leading to improved overall performance. The harness’s durable construction and reliable design contribute to increased safety and reduced maintenance needs. Furthermore, its precise engineering ensures compatibility with a wide range of commercial truck models, making it a versatile choice for fleet operators 2.

Installation Process

Installing the Cummins 3642490 Wiring Harness requires careful attention to detail and adherence to best practices. Begin by disconnecting the truck’s battery to prevent electrical shocks or short circuits. Next, route the harness through the designated pathways within the truck, ensuring that it is securely fastened and protected from potential damage. Connect the harness to the battery, ECM, and other electrical components using the provided connectors. Finally, test the installation by reconnecting the battery and checking for proper functionality of all connected systems.

Common Issues and Troubleshooting

Wiring harnesses, including the Cummins 3642490, may encounter issues such as loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, begin by visually inspecting the harness for any signs of damage or wear. Check all connections to ensure they are secure and properly aligned. If a specific electrical component is not functioning, trace the wiring back to identify any breaks or shorts. Repairing or replacing damaged sections of the harness may be necessary to restore full functionality.

Maintenance Tips

Regular maintenance of the Cummins 3642490 Wiring Harness is important for ensuring its longevity and optimal performance. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean the harness and its connectors to remove any dirt or debris that may interfere with electrical conductivity. Additionally, ensure that all connections remain tight and secure to prevent electrical issues. Following these maintenance practices will help to extend the life of the wiring harness and maintain the efficiency of the truck’s electrical system.

Safety Considerations

When working with the Cummins 3642490 Wiring Harness, it is important to observe several safety protocols. Always disconnect the truck’s battery before beginning any work on the electrical system to avoid the risk of electrical shock or short circuits. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from potential hazards. Additionally, ensure that all tools and equipment used during installation or maintenance are in good condition and suitable for electrical work.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company offers a wide range of products and services designed to meet the diverse needs of its customers, from engines and powertrains to aftermarket parts and digital solutions.

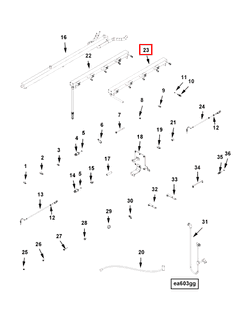

Cummins Wiring Harness 3642490 in Engine Applications

The Cummins Wiring Harness 3642490 is a component designed to ensure seamless electrical connectivity in various Cummins engines. This wiring harness is engineered to integrate smoothly with the following engines:

- QSK60 CM500

The QSK60 CM500 engine, known for its robust performance and reliability, relies on the 3642490 wiring harness to manage its electrical systems efficiently. This harness is meticulously crafted to handle the specific electrical demands of the QSK60 CM500, ensuring that all components receive the necessary power and signals for optimal operation.

The wiring harness is designed to fit precisely within the engine’s architecture, connecting various electrical components and sensors. Its placement is critical, as it must be able to withstand the engine’s operational environment, including heat, vibrations, and exposure to various elements. The harness’s design facilitates easy installation and maintenance, allowing for quick troubleshooting and repairs.

In the QSK60 CM500, the wiring harness plays a pivotal role in maintaining the engine’s performance and efficiency. It ensures that all electrical systems, including the engine control unit (ECU), sensors, and actuators, are properly connected and functioning. This integration is essential for the engine’s overall reliability and longevity.

The 3642490 wiring harness is a testament to Cummins’ commitment to quality and durability. Its design reflects an understanding of the unique challenges faced by heavy-duty engines, ensuring that the QSK60 CM500 operates at peak performance under demanding conditions.

Role of Part 3642490 Wiring Harness in Engine Systems

The Part 3642490 Wiring Harness is a component that facilitates the integration and operation of various engine systems. It acts as the central nervous system for the engine, ensuring that all electrical and electronic components communicate effectively and function harmoniously.

Integration with Accessories

The wiring harness connects various accessories to the engine’s electrical system. These accessories may include fuel pumps, cooling fans, and ignition systems. By providing a structured pathway for electrical signals and power, the harness ensures that these accessories receive the necessary voltage and current to operate efficiently. This integration allows for the seamless operation of engine-driven accessories, enhancing overall engine performance and reliability.

Electrical System Coordination

Within the electrical system, the wiring harness plays a pivotal role in distributing power from the battery to various components such as lights, sensors, and actuators. It ensures that each component receives the correct voltage, preventing issues such as overloading or under-voltage conditions that could lead to malfunctions. The harness also facilitates the return path for electrical current, maintaining a balanced electrical system and preventing ground faults.

Connection to Electronic Control Module (ECM) Kit

The wiring harness is integral to the operation of the Electronic Control Module (ECM) kit. It provides the necessary connections between the ECM and other engine components, allowing the ECM to monitor and control various engine functions. This includes fuel injection, ignition timing, and emissions control. The harness ensures that the ECM receives accurate data from sensors and can send precise commands to actuators, optimizing engine performance and efficiency.

Enhanced Diagnostic Capabilities

By providing a structured and organized pathway for electrical signals, the wiring harness also enhances the diagnostic capabilities of the engine system. Technicians can trace electrical issues more effectively, identify faults in specific circuits, and perform repairs with greater accuracy. This leads to reduced downtime and more efficient maintenance procedures.

Conclusion

The Cummins 3642490 Wiring Harness is a fundamental component that ensures the proper functioning and integration of accessories, the electrical system, and the ECM kit within engine systems. Its role in facilitating communication and power distribution is essential for the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.