This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3643638 Wiring Harness is a specialized component designed for use in commercial trucks. It plays a role in the vehicle’s electrical system by facilitating the connection between various electrical components and the truck’s power source. This integration ensures that all electrical systems within the truck operate in unison, contributing to the vehicle’s overall functionality and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It consists of insulated wires bundled together, often secured with ties or conduits, and includes connectors that allow for easy integration with other parts of the vehicle’s electrical system. The primary function of a wiring harness is to organize and protect the wires, reducing the risk of short circuits and ensuring efficient signal transmission 1.

Purpose of the 3643638 Wiring Harness

This Cummins part is designed to provide a structured and secure pathway for electrical signals and power. It connects various electrical components, such as sensors, lights, and control units, to the truck’s battery and other power sources. This integration ensures that all electrical systems within the truck operate in unison, contributing to the vehicle’s overall functionality and safety.

Key Features

The 3643638 Wiring Harness is characterized by its robust design and the quality of materials used in its construction. It is built to withstand the harsh conditions often encountered in commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness features high-quality insulation and durable connectors, which enhance its performance and longevity. Additionally, its design allows for easy integration with other systems and components within the truck.

Benefits

The use of the 3643638 Wiring Harness offers several advantages in truck operations. It contributes to improved reliability by ensuring secure and consistent electrical connections. This reliability is crucial for the safe and efficient operation of the truck. Furthermore, the harness enhances efficiency by optimizing the transmission of electrical signals and power, reducing the likelihood of electrical failures. Safety is also improved, as the harness helps prevent electrical shorts and other hazards that could arise from poorly managed wiring 2.

Installation Considerations

When installing the 3643638 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration and functionality. Preparatory steps include ensuring the truck’s electrical system is compatible with the harness and that all existing wiring is in good condition. Tools required for installation may include wire cutters, strippers, and crimping tools. Common pitfalls to avoid include improper securing of the harness, which can lead to damage from vibrations, and incorrect connections, which can cause electrical issues.

Troubleshooting Common Issues

Frequent problems associated with wiring harnesses can include loose connections, damaged wires, and faulty connectors. Diagnosing these issues involves inspecting the harness for signs of wear or damage and testing electrical connections for continuity and proper function. Recommended solutions or repairs may include tightening connections, replacing damaged wires or connectors, and ensuring the harness is properly secured within the truck.

Maintenance Tips

Routine maintenance practices are key to ensuring the longevity and optimal performance of the 3643638 Wiring Harness. This includes regular inspection for signs of wear, damage, or corrosion, and cleaning the harness to remove dirt and debris that could affect its performance. Care instructions may also involve applying protective coatings to vulnerable areas and ensuring all connections remain secure and dry.

Safety Precautions

When working with the 3643638 Wiring Harness, it is important to observe electrical safety practices and use personal protective equipment (PPE) to prevent injury. This includes wearing insulated gloves and safety glasses, ensuring the truck’s battery is disconnected before beginning work, and using tools with insulated handles. Adhering to these safety measures helps protect against electrical shocks and other hazards associated with working on vehicle electrical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engines, powertrains, and components designed to meet the demanding requirements of commercial vehicle operations. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 3.

Role of Part 3643638 Wiring Harness in Engine Systems

The 3643638 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various engine components.

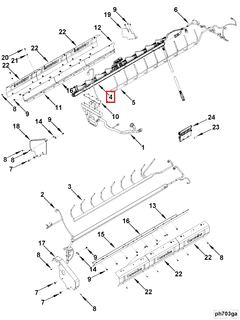

Integration with Assembly B Bank Harness

The 3643638 Wiring Harness interfaces with the Assembly B Bank Harness to ensure efficient power delivery and signal transmission to the engine’s cylinder bank B. This integration is essential for maintaining balanced engine performance and ensuring that each cylinder operates within optimal parameters.

Connection to Engine Control Module (ECM)

A key function of the 3643638 Wiring Harness is its connection to the Engine Control Module (ECM). This harness transmits critical data from various sensors to the ECM, allowing for real-time monitoring and adjustment of engine operations. It also relays commands from the ECM to actuators and other control units, ensuring that the engine responds accurately to driving conditions and load requirements.

Coordination with Wiring Assembly Harness

The 3643638 Wiring Harness works in tandem with the Wiring Assembly Harness to create a comprehensive network that covers all electrical connections within the engine bay. This coordinated effort ensures that power and data signals are distributed effectively, reducing the risk of electrical faults and enhancing overall system reliability.

General Wiring Harness Functions

Beyond specific integrations, the 3643638 Wiring Harness plays a broader role in the engine’s electrical system. It connects various sensors, actuators, and control units, ensuring that all components can communicate and function in harmony. This comprehensive connectivity is vital for the engine’s performance, efficiency, and durability.

Conclusion

The Cummins 3643638 Wiring Harness is a critical component in the electrical systems of commercial trucks and engines, ensuring reliable and efficient operation. Its robust design, high-quality materials, and integration capabilities make it an essential part of modern vehicle electrical systems. Proper installation, maintenance, and safety precautions are crucial to maximizing the benefits of this part.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.