This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3644384 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. Its role is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by connecting components such as lights, sensors, and control units to the power source and each other, enabling the vehicle to operate correctly 1.

Purpose of the 3644384 Wiring Harness

The Cummins 3644384 Wiring Harness is specifically engineered to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s engine, transmission, and various electrical components, ensuring that power and signals are transmitted efficiently. This integration is vital for the operation of features such as engine management systems, lighting, and diagnostic tools, contributing to the truck’s overall functionality and performance 2.

Key Features

The 3644384 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the harsh conditions often encountered in commercial truck operations, including exposure to vibrations, temperature extremes, and moisture. Unique characteristics of this wiring harness include its compact design, which allows for easier installation and maintenance, and its durability, which ensures long-term reliability in demanding environments 3.

Benefits of Using the 3644384 Wiring Harness

Utilizing the Cummins 3644384 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring reliable electrical connections, which can lead to better fuel economy and reduced downtime. The harness’s design enhances the reliability of the truck’s electrical systems, minimizing the risk of failures. Additionally, by providing a secure and organized method for managing wires, it plays a role in enhancing safety by reducing the likelihood of electrical fires and other hazards 4.

Installation Considerations

When installing the Cummins 3644384 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include inspecting the installation area for any potential obstructions or damage that could affect the harness’s performance. Tools required for installation may vary but typically include wire cutters, strippers, and crimping tools. Careful attention to detail during installation helps ensure the harness functions as intended 5.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Cummins 3644384 Wiring Harness, regular maintenance is recommended. This may include inspecting the harness for signs of wear or damage, ensuring connections are secure, and cleaning the harness to remove any debris that could affect its operation. Common issues that may arise include loose connections or damaged wires, which can often be addressed by tightening connections or repairing damaged sections as needed 6.

Safety Precautions

When working with the Cummins 3644384 Wiring Harness, observing important safety measures is crucial. Electrical safety practices, such as ensuring the truck’s battery is disconnected before beginning work, help prevent electrical shocks or short circuits. Handling guidelines for the harness should be followed to avoid damage to the wires or connectors, ensuring the harness remains in good working condition 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established itself as a key player in the commercial truck industry, providing reliable and efficient power solutions. Its commitment to innovation and quality has made Cummins a trusted name among commercial truck operators worldwide 8.

Wiring Harness 3644384 Compatibility with Cummins Engines

The Wiring Harness 3644384, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connectivity and performance. This part is crucial for maintaining the operational integrity of the engine’s electrical system.

QSK45 CM500 and QSK60 CM500

Both the QSK45 CM500 and QSK60 CM500 engines benefit from the 3644384 Wiring Harness. This harness is engineered to handle the electrical demands of these engines, ensuring that all necessary components receive the appropriate power and signals. Its design allows for easy installation and compatibility with the specific electrical architecture of these models.

QSK60 CM850 MCRS and QSK78 CM500

The 3644384 Wiring Harness is also compatible with the QSK60 CM850 MCRS and QSK78 CM500 engines. These engines, while differing in some specifications, share a common electrical framework that the harness is designed to support. The harness’s robust construction and precise wiring layout ensure that it can effectively manage the electrical requirements of these engines, contributing to their overall efficiency and reliability.

QSK95 CM2350 K111 and QSK95 CM2350 K113

Finally, the 3644384 Wiring Harness is suitable for use with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines, known for their high power output and advanced features, require a wiring harness that can deliver consistent and reliable electrical performance. The 3644384 harness meets these demands, providing a seamless fit and ensuring that all electrical components are properly connected and functioning.

Role of Part 3644384 Wiring Harness in Engine Systems

The 3644384 Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless electrical connectivity and functionality.

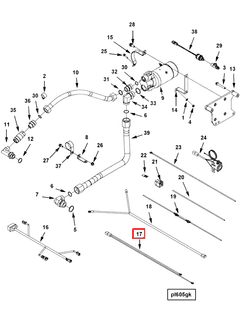

Integration with Electrical Set Accessories

The wiring harness is the backbone that connects the electrical set accessories to the engine’s electrical system. It facilitates the transmission of power and signals to components such as sensors, gauges, and control modules. This ensures that these accessories operate efficiently, providing accurate readings and enabling precise control over engine parameters.

Coordination with Primer System

In conjunction with the primer system, the 3644384 Wiring Harness plays a significant role in preparing the engine for start-up. It ensures that the electrical signals required to activate the primer are transmitted accurately. This is essential for the proper atomization of fuel, which in turn aids in a smoother and more reliable engine start, especially in cold conditions.

Support for Engine Lubricating System

The wiring harness also interfaces with the engine lubricating system by connecting oil pressure sensors and lubrication control modules. It ensures that the electrical signals indicating oil pressure and temperature are accurately conveyed to the engine control unit (ECU). This allows the ECU to make real-time adjustments to maintain optimal lubrication, thereby protecting engine components from wear and ensuring longevity.

Conclusion

In summary, the 3644384 Wiring Harness by Cummins is a versatile and essential component for maintaining the electrical integrity of a range of Cummins engines, from the QSK45 CM500 to the QSK95 CM2350 K113 series. It plays a vital role in ensuring the reliable operation of various engine systems by providing the necessary electrical connections and signal transmissions.

-

An Introduction to Engine Testing and Development, Richard D. Atkins, SAE International, 2009

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

B4.5 CM2350 B129B, Service Manual (5411247)

↩ -

An Introduction to Engine Testing and Development, Richard D. Atkins, SAE International, 2009

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

B4.5 CM2350 B129B, Service Manual (5411247)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.