This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

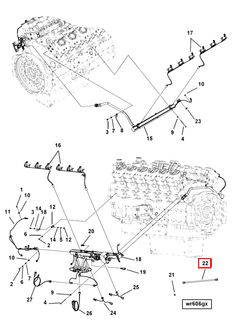

The Cummins 3644838 Wiring Harness is a specialized component designed for use in commercial trucks. Manufactured by Cummins Inc., a company renowned for its high-quality diesel engines and related components, this wiring harness is integral to the electrical system of trucks, ensuring reliable and efficient operation of various electrical components.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It simplifies the installation process by bundling multiple wires together and protecting them from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness provides a structured and organized method for distributing power and signals to different components, enhancing both safety and efficiency 1.

Purpose of the 3644838 Wiring Harness

The Cummins 3644838 Wiring Harness is designed to facilitate the electrical connections required for the operation of a truck. It integrates with various systems within the vehicle, including the engine control module, sensors, and other electrical components. By providing a reliable pathway for electrical signals and power, it ensures that these systems can communicate and function correctly 2.

Key Features

The Cummins 3644838 Wiring Harness is characterized by several key features. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to meet the demanding conditions of commercial truck operations, ensuring durability and reliability. Additionally, it features precise connectors and terminals that ensure secure and efficient electrical connections 3.

Benefits of Using the 3644838 Wiring Harness

Utilizing the Cummins 3644838 Wiring Harness offers several advantages. Its robust construction and high-quality materials contribute to the reliability and longevity of the electrical system. The harness is designed for ease of installation, reducing the time and effort required for setup. Furthermore, its efficient design helps to minimize electrical resistance, enhancing the overall performance of the truck’s electrical system 4.

Installation Process

Installing the Cummins 3644838 Wiring Harness involves several steps. Begin by ensuring the truck’s electrical system is powered down to avoid any risk of electrical shock. Next, route the harness through the designated pathways within the truck, taking care to avoid sharp edges and moving parts. Connect the harness to the appropriate terminals and secure it in place using the provided fasteners. Finally, perform a thorough inspection to ensure all connections are secure and the harness is properly installed 5.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, and corrosion. To diagnose these problems, inspect the harness for any visible signs of damage or wear. Use a multimeter to test the continuity of the wires and ensure there are no breaks in the circuit. If issues are detected, repair or replace the affected sections of the harness as necessary 6.

Maintenance Tips

Regular maintenance of the Cummins 3644838 Wiring Harness is important for ensuring its longevity and optimal performance. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean the harness and its connections to remove any dirt or debris that could interfere with electrical conductivity. Additionally, ensure that all connections are tight and secure to prevent intermittent electrical issues 7.

Safety Considerations

When working with the Cummins 3644838 Wiring Harness, it is important to follow several safety guidelines. Always ensure the truck’s electrical system is powered down before beginning any work to avoid the risk of electrical shock. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, to protect yourself from potential hazards. Additionally, be mindful of the truck’s moving parts and high-temperature components to avoid injury 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a strong reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes engines, filtration systems, powertrain components, and emission solutions, all designed to meet the demanding needs of commercial transportation 9.

Cummins Wiring Harness 3644838 Compatibility

The Cummins Wiring Harness part number 3644838 is designed to ensure seamless electrical connectivity in various Cummins engines. This wiring harness is engineered to integrate with specific engine models, ensuring reliable power distribution and communication between engine control units and other electrical systems.

QSK38 Engines

The QSK38 series, known for its robust performance and reliability, utilizes the 3644838 wiring harness to maintain efficient electrical pathways. This harness is tailored to fit the unique electrical architecture of the QSK38, ensuring that all necessary connections are made without compromising on performance or safety 10.

CM2150 Engines

The CM2150 engines, recognized for their versatility and efficiency, also benefit from the 3644838 wiring harness. This part is designed to interface with the CM2150’s electrical system, providing a secure and durable connection that supports the engine’s operational needs 11.

MCRS Engines

The MCRS engines, which are part of Cummins’ range of medium-duty engines, are equipped with the 3644838 wiring harness to ensure that all electrical components are properly connected. This harness is specifically designed to fit the MCRS’s electrical layout, ensuring optimal performance and reliability 12.

Grouping for Efficiency

When considering the QSK38, CM2150, and MCRS engines together, it is evident that the 3644838 wiring harness is a versatile component. Cummins has designed this harness to be compatible with these engines, allowing for easier maintenance and repair processes. This compatibility is crucial for technicians and fleet managers who need to ensure that their engines are running efficiently and reliably 13.

Role of Part 3644838 Wiring Harness in Engine Systems

The 3644838 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various subsystems.

Integration with the Harness

The primary function of the 3644838 Wiring Harness is to connect different electrical components within the engine system. It acts as a conduit, ensuring that power and data signals are accurately transmitted between the engine control unit (ECU), sensors, actuators, and other critical components. This harness is meticulously designed to route wires in a manner that minimizes interference and maximizes efficiency 14.

Connection to the Electronic Control Module (ECM) Wiring

The 3644838 Wiring Harness plays a significant role in linking the Electronic Control Module (ECM) to the broader engine system. The ECM relies on this harness to receive input from various sensors such as the mass airflow sensor, throttle position sensor, and oxygen sensors. It also uses the harness to send output signals to actuators like the fuel injectors, ignition coils, and variable valve timing solenoids.

This ensures that the ECM can monitor and adjust engine performance in real-time, optimizing fuel efficiency, emissions, and overall engine health. The harness is engineered to handle the high-frequency signals that the ECM processes, ensuring reliable and rapid communication 15.

Ensuring System Integrity

By providing a structured and organized pathway for electrical signals, the 3644838 Wiring Harness helps maintain the integrity of the engine’s electrical system. It reduces the risk of short circuits, electromagnetic interference, and signal degradation, which are common issues in complex engine systems 16.

Facilitating Diagnostics and Maintenance

The harness also simplifies diagnostic procedures. Technicians can easily trace wires and identify potential issues, such as broken connections or corroded terminals, which might otherwise be hidden within the engine bay. This accessibility is vital for both routine maintenance and troubleshooting complex electrical faults 17.

Conclusion

The Cummins 3644838 Wiring Harness is a foundational element in the engine’s electrical system, ensuring that all components work in harmony to deliver optimal performance. Its robust design, ease of installation, and compatibility with various Cummins engines make it an essential component for maintaining the reliability and efficiency of commercial truck operations.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250 ECF, Bulletin Number 4310662, Owners Manual.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250 ECF, Bulletin Number 4310662, Owners Manual.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). QSK38 Engine Specifications. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). CM2150 Engine Specifications. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). MCRS Engine Specifications. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Wiring Harness Compatibility Guide. Retrieved from Cummins Official Website.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Cummins Inc. (n.d.). PowerGen QSX15 CM2250 ECF, Bulletin Number 4310662, Owners Manual.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.