This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

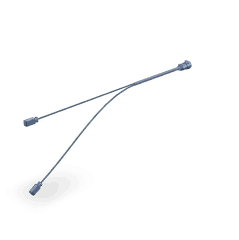

Wiring harnesses are integral components of a vehicle’s electrical system, designed to manage and route electrical signals and power throughout the vehicle. They consist of a collection of wires, connectors, and terminals that are bundled together to facilitate the transmission of electrical energy and data between various systems and components. The primary role of a wiring harness is to ensure that electrical connections are secure, organized, and protected from environmental factors, thereby enhancing the overall efficiency and reliability of the vehicle’s electrical system 1.

Purpose of the 3645032 Wiring Harness

The 3645032 Wiring Harness by Cummins is specifically engineered to play a vital role in the operation of commercial trucks. This component facilitates the connection between various electrical systems and components, ensuring that they function efficiently and reliably. By providing a structured and organized pathway for electrical signals and power, this Cummins part helps to maintain the integrity of the truck’s electrical system, supporting critical functions such as engine management, lighting, and auxiliary systems 2.

Key Features of the 3645032 Wiring Harness

The 3645032 Wiring Harness is distinguished by several key features that enhance its performance in heavy-duty applications. Constructed from high-quality materials, this wiring harness is designed to withstand the rigors of commercial truck operations. Its robust construction ensures durability, while its efficient design minimizes the risk of electrical interference and signal loss. Additionally, the harness incorporates special features such as corrosion-resistant connectors and protective coatings, which further enhance its reliability in demanding environments 3.

Benefits of Using the 3645032 Wiring Harness

Incorporating the 3645032 Wiring Harness into a truck’s electrical system offers several advantages. One of the primary benefits is improved reliability, as the harness is designed to provide secure and consistent electrical connections. This results in enhanced performance and reduced downtime. Additionally, the harness is engineered for ease of installation, which can save time and labor costs during maintenance or upgrades. Over time, the reduced need for maintenance and repairs can lead to significant cost savings, making the 3645032 Wiring Harness a valuable investment for fleet operators.

Installation and Integration

Proper installation and integration of the 3645032 Wiring Harness are critical to ensuring its optimal performance. The installation process should follow best practices to avoid common pitfalls such as improper routing, insufficient securing, or damage to the harness. Careful planning and attention to detail are necessary to ensure that the harness is correctly positioned and connected to all relevant components. Potential challenges may include navigating tight spaces or dealing with existing wiring configurations, but with careful execution, a successful installation can be achieved.

Troubleshooting Common Issues

Despite its robust design, the 3645032 Wiring Harness may encounter issues over time. Common problems can include loose connections, damaged wires, or corrosion at the terminals. Identifying these issues early is important for maintaining the harness’s performance. Diagnostic procedures may involve visual inspections, continuity tests, and voltage measurements to pinpoint the source of the problem. Repair or replacement guidelines should be followed to address any issues effectively, ensuring the harness continues to function reliably.

Maintenance Tips

Regular maintenance of the 3645032 Wiring Harness is important for ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear, corrosion, or damage. Cleaning the harness and its connections can prevent the buildup of dirt and debris, which may interfere with electrical conductivity. Additionally, it is important to monitor the harness for any signs of stress or abrasion, particularly in areas where it may come into contact with moving parts or sharp edges. When necessary, professional servicing should be considered to address more complex issues or perform thorough inspections.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial vehicle industry. The company is renowned for its commitment to quality, innovation, and customer satisfaction. Cummins’ expertise in engine and powertrain technologies extends to a wide range of applications, including on-highway and off-highway vehicles, power generation, and industrial equipment. The 3645032 Wiring Harness is a testament to Cummins’ dedication to providing reliable and high-performance components for the commercial vehicle market.

Cummins Engine Wiring Harness 3645032 Compatibility

The Cummins Wiring Harness part number 3645032 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connectivity and system functionality. This wiring harness is specifically engineered to fit within the engine architecture of the QSK50 CM2150 MCRS and QSK60 CM850 MCRS engines.

For the QSK50 CM2150 MCRS engine, the wiring harness is meticulously crafted to connect various electrical components, ensuring that power and signals are transmitted efficiently. This harness is integral to the engine’s operation, providing a robust and reliable connection that supports the engine’s performance and diagnostics.

Similarly, for the QSK60 CM850 MCRS engine, the wiring harness part number 3645032 is tailored to meet the specific electrical requirements of this engine. It ensures that all necessary connections are made accurately, facilitating smooth communication between the engine’s control systems and other electrical components.

Both engines benefit from this wiring harness by maintaining a consistent and reliable electrical network, which is crucial for optimal engine performance and longevity. The harness is designed to withstand the operational stresses of these engines, ensuring durability and reliability in demanding environments.

Role of Part 3645032 Wiring Harness in Engine Systems

The part 3645032 Wiring Harness is an integral component in the electrical system of engine setups, facilitating the seamless operation of various subsystems. It acts as the primary conduit for electrical signals and power distribution, ensuring that all connected components function harmoniously.

Integration with the Fuel System

In the fuel system, the wiring harness connects the fuel pump, fuel injectors, and the fuel level sensor to the engine control unit (ECU). This connection allows the ECU to monitor and adjust the fuel delivery based on real-time data, optimizing fuel efficiency and engine performance. The harness also ensures that the fuel pump receives the necessary power to operate, which is essential for the delivery of fuel to the engine.

Connection to the Filter System

The wiring harness also plays a significant role in the filter system by connecting sensors and actuators related to air and oil filtration. For instance, it links the air flow meter and the oil pressure sensor to the ECU. This enables the ECU to make adjustments to the air-fuel mixture and to monitor the condition of the oil, ensuring that the engine operates within optimal parameters. Additionally, the harness may connect to the filter change indicator, alerting the operator when maintenance is due.

Overall Functionality

By providing a robust and organized pathway for electrical signals and power, the part 3645032 Wiring Harness enhances the reliability and efficiency of the engine system. It reduces the risk of electrical faults by minimizing the number of individual wires needed, thus lowering the potential for short circuits and improving the overall safety of the engine operation.

Conclusion

The 3645032 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various subsystems. Its robust construction, key features, and compatibility with specific Cummins engines make it a valuable asset for fleet operators. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this Cummins part, contributing to the overall performance and longevity of the vehicle’s electrical system.

-

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Yushu Wang. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Allan Bonnick. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.