This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

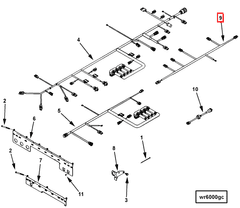

Introduction

The Cummins 3658785 Wiring Harness is a specialized component designed for use in commercial trucks. It serves a role in the vehicle’s electrical system, facilitating the connection between various electrical components and ensuring the efficient transmission of electrical signals and power. Its significance lies in its ability to support the complex electrical demands of modern trucks, contributing to overall vehicle performance and reliability.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components within a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in organizing and routing electrical connections, reducing the risk of short circuits and improving the efficiency of electrical signal transmission 1.

Purpose of the 3658785 Wiring Harness

The Cummins 3658785 Wiring Harness is designed to integrate with the electrical systems of commercial trucks, providing a structured and reliable means of connecting various electrical components. It facilitates the operation of critical systems such as the engine control unit (ECU), sensors, and other electronic modules. By standardizing connections and reducing the complexity of wiring, it contributes to the efficient functioning of the truck’s electrical system.

Key Features

The Cummins 3658785 Wiring Harness is characterized by its robust design and high-quality materials. It features durable insulation to protect against electrical interference and physical damage, ensuring reliable performance in demanding environments. The harness is engineered with precision to fit specific truck models, ensuring compatibility and ease of installation. Additionally, it incorporates unique characteristics such as corrosion-resistant connectors and flexible routing options to enhance its performance and durability.

Benefits

The Cummins 3658785 Wiring Harness offers several benefits, including improved electrical efficiency through organized and streamlined connections. It reduces the risk of short circuits by providing a structured pathway for electrical signals and power. Furthermore, its design enhances reliability, even in harsh operating conditions, contributing to the overall durability and performance of the truck’s electrical system 2.

Installation Considerations

When installing the Cummins 3658785 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Compatibility with various truck models should be verified to ensure a seamless fit. Specific installation requirements, such as securing the harness in place and ensuring all connections are tight and secure, should be adhered to for optimal performance.

Troubleshooting Common Issues

Common issues with the Cummins 3658785 Wiring Harness may include loose connections, damaged wires, or corrosion at connectors. Troubleshooting steps involve inspecting the harness for visible damage, ensuring all connections are secure, and cleaning or replacing corroded connectors as necessary. Addressing these issues promptly can help maintain the integrity and reliability of the truck’s electrical system 3.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3658785 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning connectors to prevent corrosion, and repairing or replacing any damaged sections of the harness. Adhering to these maintenance practices can help prevent electrical issues and ensure the continued reliability of the truck’s electrical system.

Safety Precautions

When working with the Cummins 3658785 Wiring Harness, it is important to observe safety precautions to prevent accidents or injuries. This includes proper handling of electrical components, adhering to electrical safety guidelines, and taking precautions to avoid electrical shocks or fires. Ensuring the truck’s battery is disconnected during installation or maintenance work is a critical safety measure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a reputation for producing high-quality components, Cummins is committed to advancing technology and delivering reliable solutions for the automotive and heavy-duty truck industries.

Compatibility

The Cummins Wiring Harness part number 3658785 is a component designed to ensure seamless electrical connectivity within various engine systems. This wiring harness is engineered to fit into specific engine models, ensuring compatibility and reliability.

QST30 CM552 Engines

The Cummins Wiring Harness 3658785 is compatible with the QST30 CM552 engines. This harness is meticulously designed to interface with the electrical architecture of these engines, facilitating efficient power distribution and communication between various engine control units and sensors. The harness’s robust construction and precise wiring layout ensure that it can withstand the operational stresses of these engines, providing a stable and reliable electrical connection.

Grouping of Compatible Engines

While the primary focus here is on the QST30 CM552 engines, it is important to note that the Cummins Wiring Harness 3658785 may also be compatible with other similar engine models within the Cummins product line. These engines typically share common electrical system architectures, making the harness adaptable to a range of engine types. Users should verify compatibility with their specific engine model to ensure proper fitment and functionality.

Role of Part 3658785 Wiring Harness in Engine Systems

The Part 3658785 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution between various subsystems.

Integration with the Engine Control Module (ECM)

The wiring harness interfaces directly with the Engine Control Module (ECM), serving as the primary conduit for data and power transmission. It ensures that the ECM receives accurate sensor data, such as temperature, pressure, and airflow metrics, which are essential for precise engine management. Conversely, it transmits control signals from the ECM to actuators, enabling real-time adjustments to fuel injection, ignition timing, and other critical parameters.

Power Distribution

Beyond data transmission, the wiring harness is responsible for distributing electrical power to various engine components. This includes supplying voltage to sensors, solenoids, and other peripherals that contribute to the engine’s operation. Its robust design ensures consistent power delivery, minimizing the risk of electrical failures that could compromise engine performance.

Sensor Connectivity

The harness plays a role in connecting an array of sensors to the ECM. These sensors monitor conditions such as engine temperature, oil pressure, and crankshaft position. The wiring harness ensures that these sensors are accurately wired, allowing the ECM to make informed decisions based on real-time data.

Actuator Control

In addition to sensors, the wiring harness facilitates the control of various actuators within the engine system. This includes components like the fuel injectors, throttle body, and variable valve timing solenoids. By providing a reliable electrical pathway, the harness ensures that these actuators respond promptly to ECM commands, optimizing engine efficiency and performance.

Grounding and Shielding

Effective grounding and shielding are paramount in maintaining the integrity of electrical signals within the engine system. The wiring harness incorporates dedicated ground wires and shielding to protect against electromagnetic interference (EMI) and radio-frequency interference (RFI). This ensures that the signals transmitted between the ECM and other components remain clear and unaffected by external electrical noise.

Diagnostic Capabilities

Modern wiring harnesses, including Part 3658785, are designed with diagnostic capabilities in mind. They often include dedicated wires for On-Board Diagnostics (OBD) systems, allowing mechanics to retrieve fault codes and perform system checks. This feature enhances the ease of troubleshooting and maintenance, contributing to overall engine reliability.

Conclusion

The Cummins 3658785 Wiring Harness is a fundamental component in the electrical system of engine modules, ensuring efficient data transmission, power distribution, and system integration. Its role in connecting sensors, actuators, and the ECM underscores its importance in maintaining optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.