This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3751240 Thrust Ring is a vital component in heavy-duty truck engines, designed to manage axial loads and maintain the alignment of engine components. Understanding its function and significance is essential for maintaining and optimizing engine performance.

Basic Concepts of Thrust Rings

A thrust ring is a mechanical component that controls axial movement within an engine by providing a bearing surface that minimizes friction and wear. In engines, thrust rings support and align parts experiencing axial loads, ensuring smooth operation and longevity 1.

Role of the 3751240 Thrust Ring in Truck Engines

The Cummins 3751240 Thrust Ring manages axial loads within the engine, particularly those experienced by the crankshaft and other rotating components. By providing a stable bearing surface, it maintains the alignment of these parts, which is crucial for the engine’s operation and reduces the risk of wear and damage 2.

Key Features of the 3751240 Thrust Ring

Crafted from high-quality materials, the 3751240 Thrust Ring is engineered to withstand the high loads and temperatures encountered in heavy-duty truck engines. Its precise design ensures optimal contact with mating surfaces, enhancing its ability to manage axial loads effectively 3.

Benefits of Using the 3751240 Thrust Ring

Incorporating the 3751240 Thrust Ring into a truck engine offers several advantages, including improved engine efficiency due to reduced friction and wear on components, enhanced reliability through better alignment and load management, and potentially extended engine life 4.

Installation Considerations

Proper installation of the 3751240 Thrust Ring is crucial for its optimal performance and longevity. Guidelines for installation include careful handling to avoid damage, correct orientation within the engine, and ensuring it is properly seated to maintain its function. Following manufacturer recommendations during installation can help prevent issues and ensure the thrust ring operates as intended.

Troubleshooting Common Issues

Typical problems associated with thrust rings can include wear, misalignment, or failure to manage axial loads effectively. Diagnosing these issues may involve inspecting the ring for signs of damage or wear, checking the alignment of engine components, and assessing the overall condition of the engine. Recommended solutions can range from cleaning and realigning components to replacing the thrust ring if necessary.

Maintenance Tips

Routine checks and maintenance procedures can help prolong the life of the 3751240 Thrust Ring and ensure continued engine performance. This includes regular inspections for wear or damage, ensuring proper lubrication, and following manufacturer guidelines for maintenance intervals. Keeping the engine clean and operating within specified parameters can also contribute to the longevity of the thrust ring.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications.

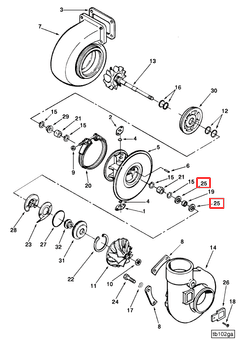

Role of Part 3751240 Thrust Ring in Engine Systems

The 3751240 Thrust Ring is an integral component in various engine systems, particularly those involving turbochargers and their assemblies. It functions to manage axial loads within the turbocharger, ensuring smooth operation and longevity of the system.

In an Aftermarket Turbocharger, the thrust ring helps in maintaining the balance of forces acting on the rotor assembly. This is essential for preventing undue wear and tear on the Core and Housing Assembly.

When integrated into a Core Assembly or a specific Core Assembly 4LGK, the thrust ring assists in stabilizing the axial movement of the rotor, which is pivotal for the efficient operation of the turbocharger.

For systems utilizing a Liner Pack or within a Performance Parts setup, the thrust ring’s role is to enhance the durability and performance of the turbocharger by reducing friction and wear between moving parts.

In the context of a Rotor Assembly 4LGZ, the thrust ring is responsible for managing the axial thrust that occurs during high-speed rotation, thus protecting the integrity of the assembly.

For Turbocharger HC3 and Heat3B Turbocharger systems, the thrust ring is a key component that ensures the turbocharger operates within its designed parameters, contributing to the overall efficiency and reliability of the engine system.

In Turbocharger and Connection assemblies, as well as Turbocharger and Mounting configurations, the thrust ring plays a supportive role in maintaining the structural integrity and operational stability of the turbocharger.

Within a Turbocharger Conversion Kit or a Turbocharger Core, the thrust ring is essential for adapting the turbocharger to different engine configurations, ensuring compatibility and optimal performance.

Finally, in a comprehensive Turbocharger Kit, the inclusion of the thrust ring is fundamental for the kit’s effectiveness, providing the necessary support for the turbocharger’s components to function harmoniously.

Conclusion

The Cummins 3751240 Thrust Ring plays a significant role in the efficiency, reliability, and longevity of heavy-duty truck engines. Its proper installation, maintenance, and understanding of its function are crucial for optimal engine performance.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.