This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

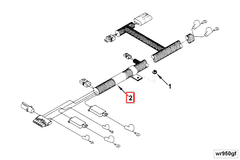

Introduction

The Cummins 3926915 Wiring Loom Assembly is a specialized component designed for use in commercial trucks. It serves as an integral element in the vehicle’s electrical system, facilitating the connection and management of various electrical components. Its role is significant in ensuring the smooth operation of the truck by providing a structured and reliable pathway for electrical signals and power.

Basic Concepts of Wiring Loom Assembly

A wiring loom assembly is a bundled set of wires and cables that are organized and protected within a sheath. This assembly is integral to a vehicle’s electrical system, allowing for the efficient transmission of electrical power and signals between different components. The components of a wiring loom typically include individual wires, connectors, and protective sheathing. The assembly functions by providing a systematic approach to wiring, reducing the risk of tangling, damage, and electrical interference 1.

Purpose of the 3926915 Wiring Loom Assembly

The 3926915 Wiring Loom Assembly plays a role in the operation of a truck by managing the electrical connections required for various systems to function correctly. It ensures that power and signals are distributed efficiently throughout the vehicle, supporting everything from engine management to lighting and auxiliary systems. By centralizing and organizing the wiring, it helps maintain the integrity and reliability of the truck’s electrical system.

Key Features

The 3926915 Wiring Loom Assembly is characterized by its robust design and the quality of materials used in its construction. It is engineered to withstand the harsh conditions often encountered in commercial trucking, including vibrations, temperature fluctuations, and exposure to chemicals. Unique characteristics of this assembly include its durable sheathing, which protects the wires from physical damage and environmental factors, and its precise engineering, which ensures a snug fit and reliable connections.

Benefits

The use of the 3926915 Wiring Loom Assembly offers several benefits. It contributes to improved electrical efficiency by ensuring that connections are secure and that power is distributed without loss. The assembly reduces the risk of electrical faults by minimizing the potential for wire damage and ensuring that all connections are properly insulated. Additionally, it enhances the overall reliability of the truck’s electrical system, leading to fewer downtimes and more consistent performance 2.

Installation Considerations

Proper installation of the 3926915 Wiring Loom Assembly is vital to ensure optimal performance and longevity. It is important to follow manufacturer guidelines closely, paying attention to the routing of the wires to avoid sharp edges or moving parts that could cause damage. Secure mounting and the use of appropriate fasteners are also critical to prevent the assembly from shifting or coming into contact with potentially damaging elements. Careful attention to these details during installation will help maintain the integrity of the electrical system.

Troubleshooting and Maintenance

Regular inspection and maintenance of the 3926915 Wiring Loom Assembly are recommended to ensure its continued reliable operation. Common issues may include worn or damaged wires, loose connections, or signs of overheating. Troubleshooting should begin with a visual inspection for any obvious signs of damage or wear. Maintenance practices include cleaning the assembly to remove any dirt or debris that could affect performance, checking connections for tightness, and replacing any damaged sections as necessary.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. Known for its commitment to quality and innovation, Cummins has a long history of producing reliable and high-performance components. The company’s dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that each product meets the high standards expected in the industry.

Compatibility with Cummins Engines

4B3.9 and 6B5.9 Engines

The Wiring Loom Assembly part 3926915 is specifically designed to fit the Cummins 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as construction equipment, agricultural machinery, and industrial power systems.

Integration and Functionality

When installed in the 4B3.9 and 6B5.9 engines, the Wiring Loom Assembly part 3926915 ensures that all electrical connections are properly routed and protected. This assembly is crucial for maintaining the integrity of the engine’s electrical system, preventing potential issues such as short circuits, signal interference, and component failures.

Installation Considerations

Proper installation of the Wiring Loom Assembly part 3926915 is essential to ensure optimal performance. Technicians should follow the manufacturer’s guidelines for routing and securing the wiring loom to avoid damage and ensure a snug fit. This part is designed to be durable and withstand the harsh conditions often encountered in heavy-duty environments.

Maintenance and Reliability

Regular inspection and maintenance of the Wiring Loom Assembly part 3926915 are recommended to prevent wear and tear. Ensuring that all connections are secure and free from corrosion will help maintain the reliability and efficiency of the engine’s electrical system. Cummins has designed this part to be a long-lasting component, contributing to the overall longevity of the engine.

Role of Part 3926915 Wiring Loom Assembly in Engine Systems

The Part 3926915 Wiring Loom Assembly is an integral component in the electrical system of engine setups, ensuring seamless connectivity and efficient operation of various subsystems.

Integration with Starting Aid Kit

When integrated with the Starting Aid Kit, the Wiring Loom Assembly facilitates the electrical connections required for the kit to function effectively. This includes providing power to the starter motor, ensuring that the engine can be started under various conditions, whether it be cold starts or routine operations. The assembly also manages the connections to any additional components within the Starting Aid Kit, such as glow plugs or preheating elements, which are essential for diesel engines.

Coordination with Wiring Accessories

In conjunction with Wiring Accessories, the Wiring Loom Assembly plays a pivotal role in maintaining a tidy and organized electrical system. It routes and secures wires to prevent tangling and potential short circuits, which could lead to engine malfunctions. The assembly also ensures that all accessories, such as sensors, switches, and control modules, receive the necessary power and signals to operate correctly. This is particularly important for modern engines that rely heavily on electronic control units (ECUs) for optimal performance and efficiency.

Conclusion

The Cummins 3926915 Wiring Loom Assembly is a critical component for the reliable and efficient operation of commercial trucks and Cummins engines. Its robust design, durable materials, and precise engineering ensure that it can withstand the harsh conditions of heavy-duty applications. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential to maximize the benefits of this part, contributing to the overall performance and reliability of the vehicle’s electrical system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.