This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Wiring harnesses are essential components in automotive electrical systems, designed to organize and route electrical wires and cables efficiently. They consist of a collection of wires, connectors, and terminals bundled together to facilitate the transmission of electrical signals and power throughout a vehicle. The primary role of a wiring harness is to ensure that electrical components are properly connected, reducing the risk of short circuits and enhancing the overall reliability of the vehicle’s electrical system. Typical components included in a wiring harness are insulated wires, connectors, terminals, and protective coverings 1.

Purpose of the Cummins 3975960 Wiring Harness

The Cummins 3975960 Wiring Harness is specifically designed to play a significant role in the operation of commercial trucks. It facilitates the necessary electrical connections for various truck systems, ensuring that components such as the engine, transmission, lighting, and other electrical subsystems function correctly. By providing a structured and organized method for routing and protecting wires, this Cummins part helps maintain the integrity of the electrical system, contributing to the overall performance and reliability of the truck 2.

Key Features of the 3975960 Wiring Harness

The Cummins 3975960 Wiring Harness is characterized by several key features that enhance its functionality and durability. It is constructed using high-quality materials, including robust insulation and corrosion-resistant connectors, to withstand the demanding conditions of commercial truck environments. The design elements of the harness include organized wire routing, secure connections, and protective coverings that shield the wires from physical damage and environmental factors. These features contribute to the harness’s ability to deliver reliable electrical performance over time 3.

Benefits of Using the 3975960 Wiring Harness

Utilizing the Cummins 3975960 Wiring Harness offers several advantages for commercial truck operators. The harness provides improved reliability by ensuring secure and consistent electrical connections. Its design also facilitates ease of installation, reducing the time and effort required for setup. Additionally, the enhanced performance of the electrical system contributes to the overall efficiency and functionality of the truck. These benefits impact the operation and maintenance of commercial trucks by promoting smoother, more dependable performance and minimizing the likelihood of electrical issues.

Installation and Integration

Proper installation of the Cummins 3975960 Wiring Harness is essential for ensuring its effective integration into the truck’s electrical system. Guidelines for installation include careful routing of the harness to avoid sharp edges and moving parts, secure attachment of connectors, and verification of all connections. The harness is designed to be compatible with various truck models and systems, though it is important to consult specific compatibility information to ensure a proper fit. Tips for a secure and efficient integration include following manufacturer instructions, using appropriate tools, and conducting thorough testing post-installation to confirm functionality.

Troubleshooting Common Issues

Common problems that may arise with wiring harnesses include loose connections, damaged wires, and corrosion at terminals. To diagnose and resolve these issues, a step-by-step troubleshooting guide can be followed. This includes visual inspection of the harness for signs of wear or damage, testing electrical connections for continuity, and repairing or replacing any faulty components. Recommendations for preventive maintenance include regular inspections, cleaning terminals to prevent corrosion, and protecting the harness from physical damage.

Maintenance Tips for Wiring Harnesses

To ensure the longevity and optimal performance of the Cummins 3975960 Wiring Harness, regular maintenance is essential. Best practices include conducting routine inspections to check for signs of wear, damage, or corrosion. Cleaning procedures should be performed to remove dirt and debris that could affect electrical connections. Replacement guidelines suggest that any damaged sections of the harness should be repaired or replaced promptly to maintain system integrity. Adhering to manufacturer recommendations for maintenance helps preserve the harness’s functionality and reliability.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins provides reliable and high-performance components for commercial vehicles. The company’s dedication to advancing technology and meeting the needs of its customers underscores its role in the automotive industry, ensuring that commercial vehicles operate efficiently and reliably.

Cummins Wiring Harness 3975960 Compatibility with Engine Models

The Cummins Wiring Harness part number 3975960 is designed to integrate seamlessly with a range of Cummins engine models. This wiring harness is a critical component in ensuring the electrical systems of these engines function correctly. Below is a detailed description of how this part fits with specific Cummins engines.

ISL G CM2180

The ISL G CM2180 engine is a high-performance, heavy-duty engine often used in various industrial applications. The wiring harness 3975960 is engineered to connect with the electrical components of the ISL G CM2180, ensuring that all sensors, actuators, and control units are properly linked. This integration is crucial for maintaining optimal engine performance and reliability.

L GAS PLUS CM556

The L GAS PLUS CM556 engine is another robust model in the Cummins lineup, known for its efficiency and durability. The wiring harness 3975960 is specifically tailored to interface with the electrical architecture of the L GAS PLUS CM556. This ensures that all electrical signals are transmitted accurately, which is vital for the engine’s operational integrity and overall performance.

Grouping of Engines

Both the ISL G CM2180 and L GAS PLUS CM556 engines fall under the category of heavy-duty, high-performance engines. The wiring harness 3975960 is designed to cater to the complex electrical needs of these engines, ensuring compatibility and seamless integration. This part is essential for maintaining the electrical integrity of these engines, which is critical for their performance and longevity.

Role of Part 3975960 Wiring Harness in Engine Systems

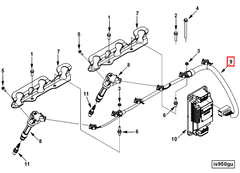

The 3975960 Wiring Harness is an integral component in the electrical architecture of engine systems, specifically interfacing with the system and ignition components.

In the system, the wiring harness facilitates the connection between various electrical components, ensuring seamless communication and power distribution. It acts as the conduit for signals and power, linking the engine control unit (ECU) with sensors, actuators, and other electronic modules. This enables the system to monitor and adjust engine performance in real-time, optimizing fuel efficiency, emissions, and overall engine health.

For the ignition system, the wiring harness plays a pivotal role in delivering consistent and reliable power to the ignition coils and spark plugs. It ensures that the ignition system receives the necessary voltage at the precise moments required for combustion, thereby maintaining engine start-up reliability and consistent operation. The harness also integrates with the ignition control module, allowing for precise timing and control of the spark delivery.

Overall, the 3975960 Wiring Harness is essential for the efficient and effective operation of both the system and ignition components within the engine, ensuring that all electrical connections are secure, reliable, and capable of handling the demands of modern engine systems.

Conclusion

The Cummins 3975960 Wiring Harness is a critical component for the reliable and efficient operation of commercial trucks. Its high-quality construction, ease of installation, and compatibility with various engine models make it an invaluable part of the vehicle’s electrical system. Regular maintenance and proper installation are key to ensuring the longevity and performance of this part, contributing to the overall reliability and efficiency of commercial trucks.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.