This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

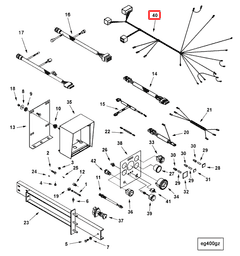

The Cummins 4000522 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. Its role is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different parts of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness provides a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 1.

Purpose of the 4000522 Wiring Harness

The Cummins 4000522 Wiring Harness is engineered to integrate seamlessly with a truck’s electrical system, connecting various components such as sensors, control modules, and actuators. It facilitates the transmission of electrical signals and power, enabling the operation of critical systems including engine management, lighting, and diagnostic functions. Its design allows for efficient integration with other systems and components, enhancing the overall functionality of the truck 2.

Key Features

The 4000522 Wiring Harness is characterized by its robust design and the use of high-quality materials. It incorporates features such as corrosion-resistant connectors, durable insulation, and a compact design that allows for easy installation and maintenance. These attributes contribute to its performance and durability, ensuring reliable operation in the demanding environments typical of commercial truck applications 3.

Benefits of Using the 4000522 Wiring Harness

Utilizing the Cummins 4000522 Wiring Harness offers several advantages. It enhances the efficiency of the truck’s electrical system by providing a reliable and organized pathway for electrical signals and power. This results in improved system performance and reduced risk of electrical failures. Additionally, the harness contributes to the safety of truck operations by ensuring that electrical components function correctly and reliably 4.

Installation Considerations

When installing the Cummins 4000522 Wiring Harness, it is important to follow guidelines and best practices to ensure compatibility with the truck’s electrical system and other components. Proper installation involves careful routing of the harness to avoid interference with other parts and ensuring secure connections at all points. Compatibility with various truck models and systems should be verified to ensure optimal performance 5.

Maintenance and Troubleshooting

Maintaining the Cummins 4000522 Wiring Harness involves regular inspection for signs of wear, corrosion, or damage. Common issues may include loose connections, damaged wires, or faulty connectors. Performing basic troubleshooting, such as checking for continuity and ensuring secure connections, can help identify and resolve problems, ensuring the harness continues to operate efficiently 6.

Safety Precautions

When working with the Cummins 4000522 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring the vehicle’s power is off before beginning any work, using insulated tools, and avoiding contact with live electrical components. Handling the harness with care, especially in areas with high vibration or exposure to the elements, is also crucial to prevent damage and ensure safe operation 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications 8.

Cummins Wiring Harness 4000522 Compatibility

The Cummins Wiring Harness 4000522 is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable and efficient electrical connectivity. This wiring harness is engineered to fit into the engine architecture of several Cummins models, providing a critical link between the engine’s electrical components and the vehicle’s overall system.

QSK19 CM500 Engines

The QSK19 CM500 engines are part of Cummins’ QSK series, known for their robust performance and reliability in heavy-duty applications. The Wiring Harness 4000522 is specifically tailored to match the electrical requirements of these engines, ensuring that all necessary connections are made without complications. This harness is crucial for maintaining the integrity of the engine’s electrical system, facilitating proper communication between the engine control unit (ECU) and other electrical components.

Integration with Cummins Engines

Cummins engines, including the QSK19 CM500, are designed with precision to ensure that parts like the Wiring Harness 4000522 fit perfectly. This harness is engineered to handle the specific electrical demands of these engines, providing a stable and reliable connection that is essential for optimal engine performance. The design of the harness ensures that it can withstand the rigors of heavy-duty operations, maintaining its integrity and functionality over time.

Compatibility and Installation

When installing the Wiring Harness 4000522, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. The harness is designed to be compatible with the QSK19 CM500 engines, but it may also fit other Cummins engines within the same series or similar models. Proper installation is crucial to avoid any electrical issues that could affect the engine’s performance or reliability.

Importance of the Wiring Harness

The Wiring Harness 4000522 plays a vital role in the overall functionality of the engine. It ensures that all electrical components are properly connected, allowing for efficient power distribution and communication within the engine system. This harness is a critical component that should be handled with care during installation and maintenance to ensure the longevity and reliability of the engine.

Role of Part 4000522 Wiring Harness in Engine Systems

The 4000522 Wiring Harness is an integral component that facilitates the electrical connections within various engine systems. It ensures seamless communication and power distribution among the engine’s electronic components.

Integration with Engine Instrument Panel

The Wiring Harness connects the Engine Instrument Panel to the vehicle’s electrical system. This connection allows the panel to receive power and transmit data from sensors and other input devices. It ensures that the panel can display vital information such as engine temperature, oil pressure, and other critical metrics to the driver.

Connection to Engine Instrument Top-Level Assembly Panel

In the Engine Instrument Top-Level Assembly Panel, the Wiring Harness plays a key role in linking multiple sub-components. It provides the necessary electrical pathways for the panel’s various gauges and indicators, enabling them to function correctly and display accurate readings.

Interaction with Instrument Panel

The Instrument Panel relies on the Wiring Harness to interface with the vehicle’s central computer system. This connection allows for the exchange of data between the panel and other systems, ensuring that all instrument readings are consistent and reliable.

Role in Instrument Panel Panel

Within the Instrument Panel Panel, the Wiring Harness ensures that all individual gauges and displays are powered and can communicate with each other. This integration is essential for the panel to provide a comprehensive view of the engine’s status and performance.

General Panel Connections

For general Panels within the engine system, the Wiring Harness serves as the backbone for electrical connectivity. It ensures that each panel component, whether it be a switch, gauge, or display, is properly powered and can send and receive data as needed.

Engine Instrument System

In the broader Engine Instrument System, the Wiring Harness connects all panels and components, creating a cohesive network. This network allows for real-time monitoring and control of the engine, enhancing overall performance and reliability.

Conclusion

The Cummins 4000522 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various engine components. Its robust design, high-quality materials, and seamless integration with Cummins engines make it an essential part for maintaining the performance and safety of commercial vehicles.

-

Livesey, A. (2000). The Repair of Vehicle Bodies. Elsevier.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elsevier.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.