This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4000676 Wiring Harness, manufactured by Cummins, is a vital component in the electrical systems of commercial trucks. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This Cummins part is designed to enhance the efficiency, reliability, and safety of truck operations by ensuring seamless electrical connectivity across various systems.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals between different components of a vehicle. It simplifies the routing of wires and reduces the risk of electrical faults. The harness typically includes insulated wires, connectors, terminals, and protective coverings. Its function is to provide a structured and organized method for electrical distribution, ensuring that each component receives the correct voltage and current 1.

Role of the 4000676 Wiring Harness in Truck Operation

The 4000676 Wiring Harness plays a significant role in the electrical system of a commercial truck. It facilitates the connection between the truck’s power source and various electrical components, such as sensors, lights, and control units. By providing a reliable pathway for electrical signals and power, the harness ensures that all systems operate efficiently and in sync. Its design allows for easy integration with other electrical components, enhancing the overall functionality of the truck 2.

Key Features of the 4000676 Wiring Harness

The 4000676 Wiring Harness is characterized by several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The design includes robust connectors and terminals that ensure secure and stable connections. Additionally, the harness is engineered to withstand the vibrations and harsh conditions typical of commercial truck operations, ensuring long-lasting reliability 3.

Benefits of Using the 4000676 Wiring Harness

Utilizing the 4000676 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted without loss or interference. The harness enhances reliability by providing a durable and stable connection system, reducing the likelihood of electrical faults. Moreover, it plays a role in safety by ensuring that all electrical components function correctly, which is crucial for the safe operation of the truck 4.

Installation and Integration

Proper installation and integration of the 4000676 Wiring Harness are vital for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines to avoid any potential issues. The harness must be routed correctly to prevent damage from heat, friction, or moving parts. Careful attention should be paid to securing all connections to ensure they remain stable under the dynamic conditions of truck operation.

Troubleshooting Common Issues

Common issues with the 4000676 Wiring Harness may include loose connections, damaged wires, or corroded terminals. To troubleshoot these problems, it is important to conduct regular inspections of the harness. Any signs of wear, corrosion, or damage should be addressed promptly. Ensuring that all connections are secure and that the harness is properly routed can help prevent many common issues.

Maintenance Tips

Maintaining the 4000676 Wiring Harness is key to ensuring its optimal performance and longevity. Regular inspections should be conducted to check for any signs of wear, damage, or corrosion. Cleaning the harness and its connections can help prevent buildup that may lead to electrical issues. Additionally, protecting the harness from physical damage and environmental factors can extend its lifespan.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a strong reputation in the automotive industry. The company has a long history of producing high-quality components and is committed to innovation and excellence. Cummins’ dedication to quality is evident in its rigorous testing and quality control processes, ensuring that all products, including the 4000676 Wiring Harness, meet the highest standards of performance and reliability.

Cummins Engine Wiring Harness 4000676 Compatibility

The Cummins Wiring Harness part number 4000676 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connectivity and performance. This wiring harness is specifically tailored to fit the following engines:

- QSK60 CM500

- QSK60G

These engines, part of the Cummins QSK series, are known for their robust performance and reliability in various industrial applications. The wiring harness is engineered to meet the specific electrical requirements of these engines, facilitating efficient power distribution and control.

For the QSK60 CM500 and QSK60G, the wiring harness ensures that all electrical components are properly connected, enhancing the overall functionality and safety of the engine system. This part is crucial for maintaining the integrity of the engine’s electrical system, providing a reliable conduit for power and signals between various engine components.

Role of Part 4000676 Wiring Harness in Engine Systems

The 4000676 Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and power distribution among key elements.

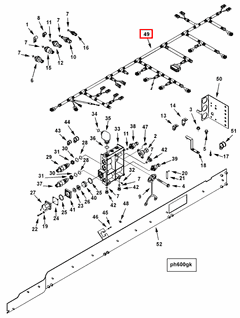

Integration with Brace Assembly Harness

The wiring harness interfaces with the brace assembly harness to facilitate the secure and organized routing of electrical cables. This integration is essential for maintaining the structural integrity of the wiring system, protecting cables from physical damage, and ensuring they remain in optimal condition for signal transmission.

Connection to the Module

Within the engine system, the 4000676 Wiring Harness plays a pivotal role in connecting to the module. This connection allows for the efficient transfer of data and power between the module and other components. The module, often responsible for processing signals and controlling various functions, relies on the wiring harness to deliver accurate and timely information, ensuring the module can perform its tasks effectively.

Link to Engine Control

The wiring harness is also fundamental in its link to the engine control system. It provides the necessary pathways for electrical signals that control the engine’s operation. This includes transmitting commands from the engine control unit (ECU) to actuators and sensors throughout the engine. The harness ensures that these signals are delivered with precision, allowing for the fine-tuned control of engine functions such as fuel injection, ignition timing, and emissions control.

Conclusion

In summary, the 4000676 Wiring Harness is a vital component that enables the efficient and reliable operation of engine systems by facilitating connections between the brace assembly harness, module, and engine control. Its role in maintaining the integrity of electrical pathways is essential for the overall performance and reliability of the engine.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.