This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4007287 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals to and from various components within a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and terminals for connecting wires to components. The harness plays a role in organizing and protecting the electrical connections, reducing the risk of short circuits and improving the reliability of the electrical system 1.

Purpose of the 4007287 Wiring Harness

The Cummins 4007287 Wiring Harness is specifically designed to integrate with the electrical system of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, ensuring they receive the necessary power and signals to operate correctly. This harness plays a role in maintaining the electrical integrity of the truck by providing a structured and protected pathway for electrical currents 2.

Key Features

The 4007287 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable insulation to protect the wires from environmental factors and mechanical stress. The harness also features precise connectors and terminals that ensure secure and reliable connections. These features contribute to the harness’s performance and longevity in demanding commercial truck applications 3.

Benefits of Using the 4007287 Wiring Harness

Utilizing the Cummins 4007287 Wiring Harness offers several advantages. It enhances the efficiency of the electrical system by providing a well-organized and protected pathway for electrical signals and power. The harness also improves the reliability of the truck’s electrical components, reducing the likelihood of failures. Additionally, it contributes to the safety of the electrical system by minimizing the risk of short circuits and electrical fires 4.

Installation Considerations

When installing the 4007287 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include disconnecting the battery to prevent electrical shocks and ensuring the work area is clean and free of obstructions. The necessary tools for installation typically include wire strippers, crimping tools, and electrical tape. Common pitfalls to avoid include improper wire routing, which can lead to damage or interference, and insufficient securing of the harness, which may result in movement and potential disconnections 1.

Troubleshooting Common Issues

Frequent problems associated with wiring harnesses can include loose connections, damaged wires, and corrosion at terminals. Diagnosing these issues involves visual inspection of the harness for signs of wear or damage, testing electrical continuity with a multimeter, and checking for proper voltage at various points in the system. Recommended solutions may include repairing or replacing damaged sections of the harness, tightening loose connections, and cleaning corroded terminals to restore proper function 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 4007287 Wiring Harness, regular maintenance is advisable. This includes periodic inspections for signs of wear, damage, or corrosion. Cleaning the harness to remove dirt and debris can prevent buildup that may lead to electrical issues. Additionally, ensuring that all connections are secure and that the harness is properly routed and protected can help maintain its integrity. If significant wear or damage is detected, considering replacement of the harness may be necessary to prevent potential electrical failures 3.

Safety Precautions

When working with the 4007287 Wiring Harness, observing safety measures is crucial. Electrical safety practices include disconnecting the battery before beginning any work to avoid the risk of electrical shock. Handling the harness with care to prevent damage to the wires and connectors is also important. Additionally, using appropriate personal protective equipment, such as insulated gloves and safety glasses, can further enhance safety during installation or maintenance procedures 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range and commitment to innovation have made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Cummins Engine Wiring Harness Compatibility

The Cummins part 4007287, a Wiring Harness, is designed to be compatible with a range of Cummins engines. This part is integral for ensuring proper electrical connections and system functionality within the engine. Here is a detailed look at the compatibility of this wiring harness with various Cummins engines:

K38 Series

- K38

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The K38 series engines, including the QSK38 CM2150 MCRS and QSK38 CM850 MCRS, are equipped with the 4007287 Wiring Harness. This harness ensures that all electrical components are correctly wired and integrated, facilitating smooth engine operation.

K50 Series

- K50

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The K50 series engines, such as the K50, QSK50 CM2150 MCRS, and QSK50 CM2350 K108, also utilize the 4007287 Wiring Harness. This part is specifically engineered to meet the electrical needs of these engines, ensuring reliability and efficiency.

QSK45 Series

- QSK45 CM500

The QSK45 CM500 engine is compatible with the 4007287 Wiring Harness. This harness is designed to handle the specific electrical requirements of this engine model.

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

The QSK60 series engines, including the QSK60 CM500, QSK60 CM850 MCRS, and QSK60G, are equipped with the 4007287 Wiring Harness. This ensures that the electrical systems are properly connected and functioning as intended.

QSK78 Series

- QSK78 CM500

The QSK78 CM500 engine is compatible with the 4007287 Wiring Harness. This harness is tailored to meet the electrical needs of this engine model.

QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The QSK95 series engines, such as the QSK95 CM2350 K111 and QSK95 CM2350 K113, are designed to work with the 4007287 Wiring Harness. This part ensures that the electrical systems are properly integrated and functioning.

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

The QST30 series engines, including the QST30 CM2350 T101 and QST30 CM552, are compatible with the 4007287 Wiring Harness. This harness is specifically designed to handle the electrical requirements of these engine models.

By ensuring compatibility with a wide range of Cummins engines, the 4007287 Wiring Harness provides a reliable and efficient solution for maintaining proper electrical connections across different engine models.

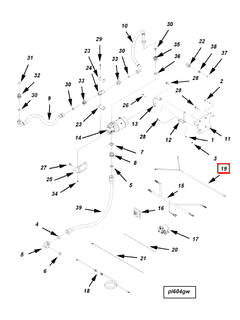

Role of Part 4007287 Wiring Harness in Engine Systems

The 4007287 Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless electrical connectivity and functionality. It serves as the vital link between the Electrical Set Accessories and the broader engine network, facilitating the transmission of electrical signals and power.

When integrated with the Kit, the Wiring Harness enhances the installation process by providing a structured and organized pathway for electrical connections. This reduces the risk of errors and improves the overall efficiency of the setup.

In conjunction with the Prelub Elect Remote, the Wiring Harness plays a significant role in the initial lubrication phase of the engine. It ensures that the electrical signals required for the remote prelub system are accurately transmitted, allowing for optimal lubrication before the engine starts.

The Motor and Starting systems rely heavily on the Wiring Harness to deliver consistent and reliable electrical power. It ensures that the motor receives the necessary voltage to function correctly, while also supporting the Starting system by providing the electrical current needed to initiate engine operation.

The Oil Priming Device Kit and Engine Oil Primer benefit from the Wiring Harness by receiving precise electrical signals. This ensures that the oil priming process is executed efficiently, preparing the engine for smooth operation.

Furthermore, the Primer and Engine Lubricating systems depend on the Wiring Harness to maintain a steady flow of electrical power. This is essential for the continuous lubrication of engine components, enhancing performance and longevity.

Lastly, the Plumbing system, although primarily mechanical, interfaces with electrical components for monitoring and control purposes. The Wiring Harness ensures that these electrical connections are secure and functional, contributing to the overall reliability of the plumbing system within the engine.

Conclusion

The Cummins 4007287 Wiring Harness is a critical component for the electrical systems of commercial trucks, ensuring efficient and reliable electrical connections across a variety of Cummins engines. Its robust design, high-quality materials, and precise connectors contribute to the overall performance and longevity of the truck’s electrical system. Regular maintenance and adherence to safety precautions are essential for maximizing the benefits of this part.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ ↩ -

Robinson, Alan and Livesey, Andrew. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ ↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ ↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.