This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4007322 Wiring Harness is a specialized component designed for use in commercial trucks. It serves a vital role in the electrical system, facilitating the connection between various electrical components and ensuring the smooth operation of the vehicle. This wiring harness is integral to maintaining the electrical integrity and functionality of the truck, contributing to overall performance and reliability 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness acts as the central nervous system, enabling communication and power distribution between different components 2.

Purpose of the 4007322 Wiring Harness

The Cummins 4007322 Wiring Harness is specifically designed to integrate with the electrical system of commercial trucks. It connects various electrical components, such as sensors, lights, and control modules, ensuring they receive the necessary power and signals to function correctly. This harness plays a role in maintaining the electrical system’s efficiency and reliability by providing a structured and protected pathway for electrical currents 3.

Key Features

The Cummins 4007322 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design includes high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to withstand the rigors of commercial truck operations, ensuring long-lasting performance. Additionally, it features precise wiring and connector placements to facilitate easy installation and maintenance 4.

Benefits

The Cummins 4007322 Wiring Harness offers several benefits that contribute to the overall efficiency and reliability of a commercial truck’s electrical system. It improves electrical efficiency by providing a direct and protected pathway for current flow, reducing the risk of short circuits and electrical faults. The harness also enhances the reliability of the electrical system, ensuring consistent performance under various operating conditions 5.

Installation Considerations

Proper installation of the Cummins 4007322 Wiring Harness is crucial for ensuring its effectiveness and longevity. It is important to follow manufacturer guidelines and use the appropriate tools and equipment during installation. Ensuring that all connections are secure and properly routed can prevent potential issues and maintain the integrity of the electrical system 6.

Troubleshooting Common Issues

Common issues with the Cummins 4007322 Wiring Harness may include electrical faults or connectivity problems. To address these issues, it is important to conduct a thorough inspection of the harness and its connections. Checking for signs of wear, corrosion, or damage can help identify potential problems. Additionally, ensuring that all connectors are securely attached and that the wiring is properly routed can resolve many common issues 7.

Maintenance Tips

Regular maintenance of the Cummins 4007322 Wiring Harness is essential for ensuring its longevity and optimal performance. This includes conducting routine inspections to check for signs of wear, corrosion, or damage. Cleaning the harness and its connections can also help prevent issues related to dirt and debris buildup. Following these maintenance tips can contribute to the overall reliability of the truck’s electrical system 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient products. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial transportation 9.

Role of Part 4007322 Wiring Harness in Engine Systems

The 4007322 Wiring Harness is an integral component that facilitates the electrical connectivity between various engine systems and accessories. Its primary function is to ensure seamless communication and power distribution among the engine’s electrical and electronic components 10.

Integration with Accessories

The wiring harness connects various accessories to the engine’s electrical system. These accessories may include fuel pumps, ignition systems, and cooling fans. By providing a structured pathway for electrical signals and power, the harness ensures that these accessories operate efficiently and in sync with the engine’s performance 11.

Electrical System Coordination

In the electrical system, the 4007322 Wiring Harness acts as the backbone, linking the battery, starter motor, and alternator. It ensures that the electrical current flows smoothly, powering the engine’s components while also managing the charging of the battery. This coordination is essential for the engine’s reliable start-up and consistent operation 12.

Monitor and Sensor Connectivity

The harness plays a significant role in connecting the engine monitor and various sensors distributed throughout the engine system. Sensors for temperature, pressure, and emissions rely on the wiring harness to transmit data to the engine control unit (ECU). This data is vital for the ECU to make real-time adjustments, optimizing engine performance and efficiency 13.

Electronic Engine Control

In modern engines equipped with electronic control systems, the 4007322 Wiring Harness is responsible for linking the ECU with actuators and solenoids. This connection allows the ECU to control fuel injection, ignition timing, and other critical functions, ensuring the engine operates within specified parameters for performance and emissions 14.

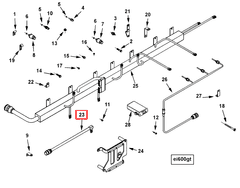

Mounting and Structural Support

Beyond its electrical functions, the wiring harness often includes mounting points and structural supports that secure it within the engine bay. This not only protects the wires from physical damage but also organizes the harness, making maintenance and troubleshooting more straightforward 15.

Engine Monitor Interface

The engine monitor, which displays various operational parameters, relies on the wiring harness to receive data from the engine’s sensors and the ECU. This interface allows for real-time monitoring of engine health, performance metrics, and diagnostic information, aiding in proactive maintenance and troubleshooting 16.

Conclusion

In summary, the Cummins 4007322 Wiring Harness is a fundamental component that ensures the electrical and electronic systems within an engine work harmoniously. Its role in connecting accessories, managing electrical flow, enabling sensor communication, controlling electronic functions, and providing structural support underscores its importance in modern engine systems 17.

-

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ -

Cummins Inc. L9 CM2350 L151C, Service Manual (6396908).

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ -

Cummins Inc. L9 CM2350 L151C, Service Manual (6396908).

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ -

Cummins Inc. L9 CM2350 L151C, Service Manual (6396908).

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ -

Cummins Inc. L9 CM2350 L151C, Service Manual (6396908).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.