This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

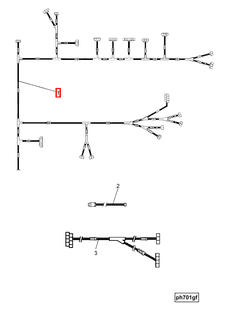

The Cummins 4010833 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as an essential element in the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This part ensures that electrical signals and power are efficiently distributed throughout the truck, supporting the operation of essential systems and features.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays, which are bundled together to transmit electrical power and signals within a vehicle 1. The components of a wiring harness include individual wires insulated to prevent short circuits, connectors that join wires together or to components, and protective housings that shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, reducing the risk of electrical faults and improving the overall efficiency of the system 2.

Purpose of the Cummins 4010833 Wiring Harness

The Cummins 4010833 Wiring Harness is specifically designed to integrate with the electrical system of commercial trucks, playing a role in connecting various electrical components to the truck’s power source. This includes facilitating the operation of lighting, signaling, and other electrical systems. Its design allows for efficient power distribution and signal transmission, ensuring that all connected systems function correctly. The harness is engineered to work in conjunction with other electrical components and systems, providing a reliable and efficient electrical pathway 3.

Key Features

The Cummins 4010833 Wiring Harness is characterized by its robust design and the use of high-quality materials. It features insulated wires to prevent electrical shorts, durable connectors for secure connections, and protective housings to shield the wires from damage. Unique attributes of this wiring harness include its resistance to environmental factors such as moisture and temperature extremes, enhancing its performance and durability in the demanding conditions often encountered by commercial trucks 4.

Benefits

The Cummins 4010833 Wiring Harness offers several advantages. It contributes to improved electrical efficiency by ensuring that power and signals are transmitted with minimal loss. The design of the harness reduces the risk of short circuits, enhancing the safety and reliability of the truck’s electrical system. Additionally, its durability and resistance to harsh operating conditions ensure that it maintains optimal performance over time, supporting the longevity and reliability of the truck’s electrical components 5.

Installation Considerations

When installing the Cummins 4010833 Wiring Harness, it is important to follow guidelines and best practices to ensure a successful installation. Preparatory steps include ensuring the truck’s electrical system is compatible with the harness and that all necessary tools are available. Common pitfalls to avoid include improper wire routing, which can lead to damage or reduced efficiency, and inadequate securing of the harness, which can result in movement and potential damage over time 6.

Troubleshooting and Maintenance

Identifying common issues with wiring harnesses involves checking for signs of wear, damage, or corrosion on the wires and connectors. Diagnostic procedures may include testing for continuity and resistance to ensure that the electrical pathways are intact and functioning correctly. Maintenance practices to ensure the longevity and optimal performance of the Cummins 4010833 Wiring Harness include regular inspections for damage, cleaning connectors to ensure good contact, and replacing any worn or damaged components as needed 7.

Safety Precautions

When working with the Cummins 4010833 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring that the truck’s electrical system is de-energized before beginning work to prevent electrical shock. Handling guidelines for the wiring harness should include avoiding sharp objects that could damage the insulation and ensuring that all connections are secure to prevent electrical faults 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 9.

Role of Part 4010833 Wiring Harness in Engine Systems

The 4010833 Wiring Harness is an integral component in the orchestration of various engine systems, facilitating seamless communication and power distribution among key elements.

Integration with Assembly Harness

The 4010833 Wiring Harness interfaces directly with the Assembly Harness, acting as a conduit for electrical signals and power. This integration ensures that all sub-systems within the assembly harness receive the necessary electrical input to function correctly. It also allows for the efficient transfer of data between the assembly harness and other engine components, enhancing overall system responsiveness 10.

Connection to Electronic Control Engine

In conjunction with the Electronic Control Engine (ECE), the 4010833 Wiring Harness plays a significant role in modulating engine performance. It transmits vital data from sensors located throughout the engine to the ECE, enabling real-time adjustments to fuel injection, ignition timing, and other parameters. This ensures optimal engine operation under varying conditions 11.

Interaction with Module

The Wiring Harness is also responsible for connecting to various modules within the engine system. These modules may include the Engine Control Module (ECM) and other specialized units. By providing a reliable electrical pathway, the harness ensures that these modules can communicate effectively with the ECE and other components, allowing for sophisticated engine management strategies 12.

Role in Engine Control

In the broader context of Engine Control, the 4010833 Wiring Harness serves as the nervous system of the engine. It enables the ECM to exert control over various actuators and sensors, ensuring that the engine operates within specified parameters. This includes managing emissions, optimizing fuel efficiency, and ensuring smooth operation 13.

Overall Functionality

In summary, the 4010833 Wiring Harness is a linchpin in the engine’s electrical system. Its role in connecting the Assembly Harness, Electronic Control Engine, Module, and Engine Control components ensures that the engine operates efficiently and effectively. The harness not only facilitates power distribution but also enables real-time data transfer, making it an indispensable part of modern engine systems 14.

Conclusion

The Cummins 4010833 Wiring Harness is a critical component in the electrical systems of commercial trucks and engines. Its robust design, high-quality materials, and resistance to environmental factors ensure reliable and efficient operation. Proper installation, maintenance, and adherence to safety precautions are essential to maximize the benefits of this part, contributing to the overall performance and reliability of the vehicle’s electrical system.

-

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.