This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Wiring harnesses are essential components in the electrical systems of vehicles, including commercial trucks. They serve as organized assemblies of wires, connectors, and terminals that facilitate the transmission of electrical power and signals between various components of the vehicle. In commercial trucks, wiring harnesses ensure that all electrical systems, from lighting to engine controls, operate efficiently and reliably. They simplify the complex network of wires, reducing the risk of electrical faults and enhancing the overall functionality of the vehicle’s electrical system 1.

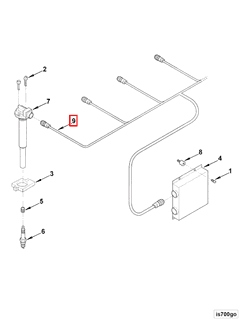

Purpose of the 4011805 Wiring Harness

The 4011805 Wiring Harness by Cummins is designed to play a specific role in the operation of trucks. It integrates with the truck’s electrical system to ensure the proper function of connected components. This harness is engineered to provide a reliable connection between various electrical components, facilitating the efficient distribution of power and signals. Its design allows for the seamless integration of new technologies and systems within the truck, enhancing overall performance and functionality 2.

Key Features of the 4011805 Wiring Harness

The 4011805 Wiring Harness is characterized by several notable features that enhance its performance and durability in heavy-duty applications. Its design incorporates high-quality materials that are resistant to wear and environmental factors, ensuring long-lasting reliability. The harness is engineered with precision to fit specific truck models, reducing the likelihood of installation errors. Additionally, it features unique attributes such as enhanced protection against electrical interference and improved connectivity options, which contribute to its superior performance in demanding conditions 3.

Benefits of Using the 4011805 Wiring Harness

Utilizing the 4011805 Wiring Harness offers several advantages. It provides improved reliability due to its robust construction and precise engineering. The harness is designed for ease of installation, which can save time and reduce the complexity of electrical system upgrades or repairs. Furthermore, its durable design contributes to reduced maintenance needs, offering long-term cost savings and ensuring consistent performance over time 4.

Installation and Integration

Proper installation of the 4011805 Wiring Harness is crucial for optimal performance. Guidelines for installation include ensuring compatibility with the specific truck model and following manufacturer recommendations for integration with the existing electrical system. Correct installation not only ensures the harness functions as intended but also contributes to the overall safety and efficiency of the truck’s electrical system.

Troubleshooting Common Issues

Identifying and resolving common problems associated with the 4011805 Wiring Harness can be facilitated through systematic diagnostic checks. Common issues may include connectivity problems or damage to the harness. Performing regular inspections and maintenance can help identify potential issues early, allowing for timely repairs and ensuring the longevity and efficient operation of the electrical system.

Maintenance Tips

Regular maintenance practices are vital to keep the 4011805 Wiring Harness in optimal condition. This includes periodic inspections for signs of wear or damage, ensuring all connections are secure, and protecting the harness from environmental factors that could lead to degradation. Proper care and maintenance can prevent electrical failures, enhance safety, and ensure the continued reliable operation of the truck’s electrical system.

About Cummins

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a rich history of innovation and expertise in the automotive industry, Cummins is renowned for its commitment to quality and performance. The company’s reputation in the commercial truck industry is built on a foundation of reliable products, advanced engineering, and a dedication to meeting the evolving needs of its customers. Cummins’ portfolio of automotive parts, including the 4011805 Wiring Harness, reflects its ongoing commitment to quality, innovation, and customer satisfaction.

Cummins Engine Wiring Harness 4011805 Compatibility

The Cummins Wiring Harness part number 4011805 is designed to integrate seamlessly with a variety of Cummins engine models. This wiring harness is a critical component that ensures the proper electrical connectivity and functionality of the engine systems. Below is a detailed description of its compatibility with specific engine models:

QSV91-G4 CM558/CM700 V102

The Wiring Harness 4011805 is specifically engineered to fit the QSV91-G4 CM558/CM700 V102 engines. This engine series is known for its robust performance and reliability, making it a popular choice in various industrial and commercial applications. The harness is designed to connect all necessary electrical components, ensuring that the engine operates efficiently and safely.

QSV91G

Similarly, the Wiring Harness 4011805 is also compatible with the QSV91G engine. This engine model is part of the same family as the QSV91-G4 CM558/CM700 V102, sharing many design and performance characteristics. The harness ensures that all electrical connections are made correctly, facilitating smooth engine operation and maintaining optimal performance.

Grouping for Compatibility

The compatibility of the Wiring Harness 4011805 with the QSV91-G4 CM558/CM700 V102 and QSV91G engines is grouped together due to their shared design and electrical system architecture. This grouping ensures that the harness can be used interchangeably across these engine models, providing a standardized solution for maintaining and repairing these engines.

Integration and Functionality

When installed, the Wiring Harness 4011805 connects various electrical components within the engine, including sensors, actuators, and control modules. This ensures that all parts of the engine’s electrical system are properly linked, allowing for accurate data transmission and control signals. The harness is designed to withstand the harsh conditions typically found in engine environments, ensuring durability and long-term reliability.

Installation Considerations

Proper installation of the Wiring Harness 4011805 is crucial for maintaining engine performance and safety. Technicians should follow the manufacturer’s guidelines for installation, ensuring that all connections are secure and that the harness is routed to avoid interference with moving parts. Regular inspection and maintenance of the harness can help prevent electrical issues and ensure the longevity of the engine’s electrical system.

Role of Part 4011805 Wiring Harness in Engine Systems

The 4011805 Wiring Harness is an integral component that facilitates the electrical connections within various engine systems. It serves as the conduit for transmitting power and signals between different parts of the engine, ensuring seamless operation and communication among components.

In the context of a Bank Wiring Harness, the 4011805 Wiring Harness is responsible for connecting multiple cylinders or groups of cylinders to the main electrical system. This ensures that each cylinder receives the necessary power and signals for ignition and fuel injection, contributing to balanced engine performance.

When integrated with an Electronic Control Engine system, the wiring harness plays a pivotal role in linking the Engine Control Module (ECM) to various sensors and actuators. This connection allows the ECM to monitor engine conditions in real-time and make adjustments to optimize performance, fuel efficiency, and emissions.

For the Engine Set V18 Harness and V18 Harness Wiring Assembly, the 4011805 Wiring Harness is essential for managing the complex electrical requirements of an 18-cylinder engine. It ensures that all cylinders, along with their respective fuel injectors, ignition coils, and sensors, are properly connected and synchronized.

In conjunction with the Ignition System, the wiring harness provides the necessary pathways for high-voltage signals required for spark plug ignition. This ensures that each cylinder fires at the correct moment, contributing to smooth and efficient engine operation.

Overall, the 4011805 Wiring Harness is a fundamental component that enhances the reliability and performance of engine systems by ensuring robust and efficient electrical connections.

Conclusion

The 4011805 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks and engines. Its robust design, precise engineering, and compatibility with various Cummins engine models make it an essential part for ensuring reliable and efficient operation. Proper installation, regular maintenance, and timely troubleshooting are key to maximizing the benefits of this Cummins part, contributing to the overall performance and longevity of the vehicle’s electrical system.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.