This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

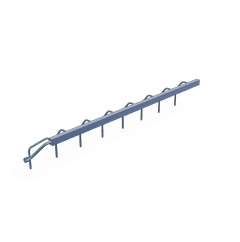

The Cummins 4013110 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different components of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and improving the efficiency of the electrical system. Within a vehicle, the wiring harness plays a role in connecting the battery to other electrical components, such as lights, sensors, and the engine control unit, ensuring that all parts of the electrical system can communicate and function correctly 1.

Purpose of the 4013110 Wiring Harness

The Cummins 4013110 Wiring Harness is designed to integrate seamlessly with the electrical systems of commercial trucks. It plays a role in distributing electrical power from the battery to various components, including the engine control module, sensors, and lighting systems. This harness is engineered to ensure that all electrical connections are secure and reliable, contributing to the efficient operation of the truck. Its design allows for easy integration with other systems and components, enhancing the overall functionality of the vehicle 2.

Key Features

The Cummins 4013110 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable materials that can withstand the harsh conditions often encountered in commercial truck operations. The harness features a compact design that allows for efficient routing of wires, minimizing the risk of damage. Additionally, it includes protective coatings and shielding to enhance its durability and performance in demanding environments 3.

Benefits of Using the 4013110 Wiring Harness

Utilizing the Cummins 4013110 Wiring Harness in commercial trucks offers several advantages. It contributes to improved efficiency by ensuring reliable electrical connections throughout the vehicle. The harness enhances the reliability of the truck’s electrical system, reducing the likelihood of malfunctions and improving overall vehicle performance. Furthermore, it plays a role in enhancing safety by providing secure and stable electrical connections, which is crucial in preventing electrical fires and other hazards associated with faulty wiring.

Installation and Integration

When installing the Cummins 4013110 Wiring Harness, it is important to follow guidelines and considerations to ensure proper integration with the truck’s electrical system. Compatibility with various truck models and systems should be verified to ensure seamless installation. Careful attention to routing and securing the harness within the vehicle is necessary to protect it from damage and ensure optimal performance. Professional installation is recommended to guarantee that all connections are made correctly and securely.

Maintenance and Troubleshooting

Maintaining the Cummins 4013110 Wiring Harness involves regular inspection for signs of wear, damage, or corrosion. Identifying common issues early can prevent more significant problems from developing. Troubleshooting procedures should be followed to diagnose and address any electrical issues that may arise. This includes checking connections, testing for continuity, and replacing any damaged components as necessary to ensure the harness continues to function correctly.

Safety Considerations

When working with the Cummins 4013110 Wiring Harness, it is important to observe safety practices and precautions to prevent accidents and ensure safe operation. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools to avoid short circuits, and ensuring that all connections are secure and properly insulated. Adhering to these safety guidelines helps protect both the technician and the vehicle from potential hazards associated with electrical work.

Cummins Overview

Cummins is a well-established company with a long history in the commercial truck industry. Known for its commitment to quality and innovation, Cummins has built a reputation for producing reliable and high-performance components for commercial vehicles. The company’s dedication to excellence is evident in its product offerings, including the Cummins 4013110 Wiring Harness, which is designed to meet the demanding requirements of commercial truck operations.

Compatibility with Engine Models

The Cummins Wiring Harness 4013110 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the stringent requirements of Cummins engines, providing a robust solution for managing electrical systems within these engines.

QSV81G Engine Series

The QSV81G engine series is known for its durability and efficiency, often utilized in heavy-duty applications. The Wiring Harness 4013110 is specifically tailored to fit within the QSV81G series, ensuring that all electrical components are properly connected and functioning. This compatibility is crucial for maintaining the operational integrity of the engine, as it facilitates the smooth transfer of electrical signals necessary for engine performance and diagnostics.

Grouping of Compatible Engines

The Cummins Wiring Harness 4013110 is not limited to a single engine model but is designed to be versatile across multiple engine types. This versatility is particularly beneficial for fleets and operators who use a range of Cummins engines, as it allows for a standardized approach to wiring harness replacement and maintenance.

By ensuring that the Wiring Harness 4013110 fits with the QSV81G engine series and other compatible models, Cummins maintains a high level of reliability and ease of maintenance for its engine users. This thoughtful design approach underscores Cummins’ commitment to providing comprehensive solutions for their customers’ needs.

Role of Part 4013110 Wiring Harness in Engine Systems

The Part 4013110 Wiring Harness is an integral component that facilitates the electrical connections within various engine systems. It ensures seamless communication and power distribution among different engine components, enhancing overall system efficiency and reliability.

In the context of a Bank Wiring Harness, the 4013110 Wiring Harness plays a pivotal role by providing the necessary electrical pathways that connect the engine’s various banks to the central control systems. This ensures that each bank operates in harmony, optimizing performance and fuel efficiency.

When integrated with an Electronic Control Engine system, the Wiring Harness acts as the backbone for data transmission and power supply. It connects sensors, actuators, and the Engine Control Module (ECM), allowing for precise monitoring and control of engine parameters such as fuel injection, ignition timing, and emissions.

In an Engine Set V16 Harness, the 4013110 Wiring Harness is essential for managing the complex electrical requirements of a V16 engine. It routes power and signals to and from the engine’s multiple cylinders, ensuring synchronized operation and efficient performance.

The Module, Engine Control relies heavily on the Wiring Harness to interface with other engine components. It facilitates the exchange of critical data and commands, enabling the ECM to make real-time adjustments for optimal engine performance.

In a V16 Harness Wiring Assembly, the Wiring Harness is designed to handle the extensive electrical network required by a V16 engine. It ensures that all components, from the fuel injectors to the ignition coils, receive the necessary power and signals to function correctly.

Finally, within a V16 Wiring Assembly Harness, the 4013110 Wiring Harness ensures that all electrical connections are secure and efficient. This comprehensive wiring solution supports the high-demand electrical systems of a V16 engine, contributing to its robust performance and reliability.

Conclusion

The Cummins 4013110 Wiring Harness is a critical component for the reliable operation of electrical systems in commercial trucks. Its robust design, high-quality materials, and compatibility with various engine models make it an essential part for ensuring efficient and safe vehicle performance. Proper installation, maintenance, and adherence to safety practices are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.