This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4063105 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to its overall operational efficiency and reliability.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to safeguard the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in ensuring that all electrical components receive the necessary power and signals to function correctly 1.

Purpose of the 4063105 Wiring Harness

The Cummins 4063105 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks powered by Cummins engines. It facilitates the connection between the engine’s electrical components, such as sensors, actuators, and control modules, and the truck’s main power source. This integration ensures that the engine’s electronic control unit (ECU) can communicate with and control various engine functions, contributing to optimal engine performance and efficiency.

Key Features

The 4063105 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable, automotive-grade wires and connectors that are resistant to corrosion, abrasion, and extreme temperatures. The harness is also designed with a high degree of flexibility, allowing it to be routed through the tight spaces within a truck’s engine compartment. Additionally, it features color-coded wires and connectors for easy identification and connection.

Benefits of Using the 4063105 Wiring Harness

Utilizing the Cummins 4063105 Wiring Harness offers several advantages. It enhances the efficiency of the truck’s electrical system by ensuring reliable and consistent power and signal transmission. The harness’s durable construction contributes to its reliability, reducing the likelihood of electrical failures. Furthermore, by facilitating proper electrical connections, it plays a role in enhancing the safety of the truck’s operation.

Installation Process

Installing the Cummins 4063105 Wiring Harness requires careful attention to detail and adherence to best practices. Begin by disconnecting the truck’s battery to prevent electrical shocks or short circuits. Next, route the harness through the engine compartment, ensuring it is secured in place with ties or clamps to prevent damage from moving parts. Connect the harness to the appropriate electrical components, following the manufacturer’s instructions for proper wire and connector alignment. Finally, re-connect the battery and test the electrical system to ensure all connections are secure and functioning correctly.

Common Issues and Troubleshooting

Typical problems with the 4063105 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these issues, begin by visually inspecting the harness for any signs of physical damage or wear. Check all connections to ensure they are secure and properly aligned. If a specific electrical component is not functioning, trace the wiring back to identify any breaks or shorts in the harness. Repairing or replacing damaged sections of the harness may be necessary to restore proper function.

Maintenance Tips

Regular maintenance of the Cummins 4063105 Wiring Harness is important for ensuring its longevity and optimal performance. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean the harness and its connections to remove any dirt or debris that may interfere with electrical conductivity. Ensure all connections are tight and secure, and replace any damaged wires or connectors as needed. Following these maintenance practices will help prevent electrical issues and ensure the reliable operation of the truck’s electrical system.

Safety Considerations

When working with the Cummins 4063105 Wiring Harness, it is important to follow safety guidelines to prevent injury or damage to the electrical system. Always disconnect the truck’s battery before beginning any work on the harness to avoid electrical shocks. Use insulated tools to prevent short circuits, and wear appropriate personal protective equipment, such as gloves and safety glasses. Additionally, be cautious of sharp edges or moving parts within the engine compartment that may cause injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company is known for its high-quality, reliable products that contribute to the efficiency and performance of commercial vehicles worldwide.

Cummins Wiring Harness 4063105 Compatibility

The Cummins Wiring Harness part number 4063105 is meticulously designed to integrate seamlessly with specific Cummins engine models. This wiring harness is a critical component in ensuring the electrical systems of the engines function optimally. It is engineered to meet the rigorous demands of the engines it supports, providing reliable connectivity and power distribution.

G855 Engines

For the G855 engines, the wiring harness 4063105 is tailored to interface with the engine’s electrical architecture. This harness ensures that all necessary electrical signals are transmitted efficiently, supporting the engine’s control systems and auxiliary functions. Its design accommodates the unique wiring requirements of the G855, ensuring compatibility and performance.

N14 G Engines

Similarly, the N14 G engines benefit from the precise engineering of the 4063105 wiring harness. This part is crafted to align with the N14 G’s electrical needs, facilitating smooth operation of the engine’s control units and other electrical components. The harness is built to withstand the operational stresses of the N14 G, providing a durable and reliable connection.

Grouping of Engines

The G855 and N14 G engines, while distinct in their design and application, share a commonality in their need for a robust and reliable wiring harness. The 4063105 part number is specifically designed to cater to the electrical requirements of these engines, ensuring that they operate at peak efficiency. This grouping highlights the versatility and adaptability of the wiring harness, making it a suitable choice for multiple engine types within the Cummins lineup.

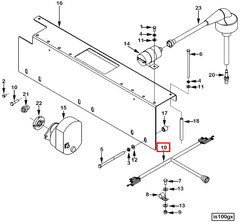

Role of Part 4063105 Wiring Harness in System and Ignition Components

The Part 4063105 Wiring Harness is integral to the seamless operation of both the system and ignition components in an engine setup.

In the system component, the wiring harness facilitates the electrical connections between various subsystems, ensuring that power is efficiently distributed. This includes linking the battery to the starter motor, the alternator, and other electrical components such as sensors and control modules. The harness also plays a role in grounding, which is essential for maintaining electrical stability and preventing issues such as short circuits.

For the ignition component, the wiring harness is responsible for connecting the ignition switch to the ignition coil and other related components. It ensures that when the ignition is turned on, the necessary electrical signals are transmitted to activate the ignition system. This includes providing power to the ignition coil, which is vital for generating the spark needed to ignite the air-fuel mixture in the combustion chamber.

Additionally, the harness supports the connection to the engine control unit (ECU), allowing for precise control over the ignition timing and other parameters that affect engine performance and efficiency.

Overall, the Part 4063105 Wiring Harness is a fundamental element that ensures the reliable and efficient operation of both the system and ignition components within the engine.

Conclusion

The Cummins 4063105 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient power and signal distribution. Its robust design, compatibility with specific Cummins engine models, and role in both system and ignition components highlight its importance in maintaining the operational efficiency and reliability of commercial vehicles.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.