This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4065244 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and ensuring efficient and reliable operation. Its role is significant in maintaining the functionality and performance of commercial trucks, which are integral to logistics and transportation industries 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow between components, enabling the operation of lights, sensors, and other electrical devices 2.

Purpose of the 4065244 Wiring Harness

The 4065244 Wiring Harness is specifically engineered to integrate with the electrical systems of commercial trucks. It connects various components such as sensors, lights, and control units, ensuring they receive the necessary power and signals to function correctly. This harness is designed to withstand the demanding conditions of commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture 3.

Key Features

The Cummins 4065244 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear and environmental factors. The harness is also designed with flexibility in mind, allowing it to be routed through the complex layout of a truck’s chassis without compromising on performance. Additionally, it features protective coatings and shielding to enhance its durability and reliability.

Benefits of Using the 4065244 Wiring Harness

Utilizing the Cummins 4065244 Wiring Harness offers several advantages. It contributes to improved electrical efficiency by ensuring a secure and direct connection between components. This reduces the risk of short circuits and electrical failures, leading to enhanced reliability. The harness is also designed to be easy to install and maintain, minimizing downtime and repair costs for fleet operators.

Installation Considerations

When installing the Cummins 4065244 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps include ensuring the truck’s electrical system is powered down and disconnected to prevent accidents. Tools required may include wire cutters, crimping tools, and electrical tape. Common pitfalls to avoid include improper routing of the harness, which can lead to damage from vibrations or heat, and insufficient securing of connections, which can result in loose or intermittent connections.

Troubleshooting Common Issues

Frequent problems associated with wiring harnesses can include loose connections, damaged wires, and corrosion. To diagnose these issues, a systematic approach is recommended. This involves visually inspecting the harness for signs of wear or damage, testing electrical connections for continuity, and using diagnostic tools to identify any faults in the electrical system. Resolving these issues may require repairing or replacing damaged sections of the harness and ensuring all connections are secure and clean.

Maintenance Tips

Regular maintenance practices are crucial for ensuring the longevity and optimal performance of the Cummins 4065244 Wiring Harness. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning connections to prevent buildup that could interfere with electrical conductivity. It is also advisable to protect the harness from physical damage by ensuring it is properly routed and secured within the truck’s chassis.

Safety Precautions

When working with the Cummins 4065244 Wiring Harness, observing important safety measures is paramount. Electrical safety protocols should be followed, including ensuring the truck’s electrical system is powered down before beginning any work. Handling guidelines should be observed to prevent damage to the harness and to ensure personal safety. This includes using appropriate tools and equipment and wearing protective gear when necessary.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

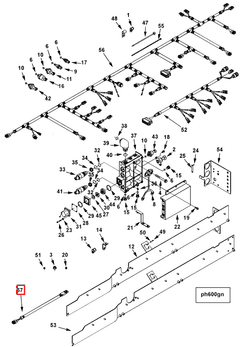

Cummins Engine Wiring Harness 4065244

The Cummins engine part 4065244, a Wiring Harness, is a component for the electrical systems of various Cummins engines. This part is integral to ensuring the proper functioning of the engine’s electrical components, facilitating communication between different parts of the engine and the vehicle’s systems.

QSK45 and CM500 Engines

For the QSK45 and CM500 engines, the Wiring Harness 4065244 is designed to manage the complex electrical requirements of these high-performance engines. These engines are often used in heavy-duty applications, such as marine and industrial settings, where reliable and robust electrical connections are paramount.

The harness is engineered to withstand the demanding conditions these engines operate under, including exposure to moisture, vibration, and extreme temperatures. It ensures that all electrical signals are transmitted accurately and efficiently, which is crucial for the optimal performance and longevity of the engines.

Integration with Engine Systems

The Wiring Harness 4065244 interfaces with various engine systems, including the engine control unit (ECU), sensors, and actuators. It ensures that the ECU can receive real-time data from the sensors and send commands to the actuators, which is essential for maintaining engine efficiency and performance.

In marine applications, the harness must also integrate with the vessel’s electrical systems, ensuring seamless communication between the engine and other onboard systems. This integration is vital for the safe and efficient operation of the vessel.

Installation and Maintenance

Proper installation of the Wiring Harness 4065244 is critical to avoid electrical faults and ensure the engine operates smoothly. Technicians must follow the manufacturer’s guidelines to ensure all connections are secure and correctly routed to prevent damage from movement and environmental factors.

Regular maintenance checks should be performed to inspect the harness for signs of wear, corrosion, or damage. Any issues detected should be addressed promptly to prevent potential engine failures or performance degradation.

Compatibility and Replacement

The Wiring Harness 4065244 is designed to be compatible with specific Cummins engine models, ensuring a precise fit and function. When replacing the harness, it is essential to use the correct part number to maintain the integrity of the engine’s electrical system.

Technicians should verify the part number and compatibility with the engine model before installation to avoid any mismatches that could lead to operational issues.

Role of Part 4065244 Wiring Harness in Engine Systems

The 4065244 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution between various modules and the Engine Control Unit (ECU).

This wiring harness acts as the central nervous system, connecting the ECU to different sensors and actuators distributed throughout the engine. It ensures that the ECU receives accurate and timely data from components such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor.

In turn, the harness enables the ECU to send control signals to actuators like the fuel injectors, ignition coils, and variable valve timing (VVT) solenoids. This bidirectional flow of information allows the ECU to make precise adjustments to fuel delivery, ignition timing, and valve timing, optimizing engine performance and efficiency.

Additionally, the 4065244 Wiring Harness plays a role in managing the electrical load within the engine system. It routes power from the battery to essential components, ensuring that each module receives the necessary voltage and current. This includes providing power to the ECU itself, as well as to ancillary systems such as the fuel pump, cooling fan, and emissions control devices.

The harness also incorporates protective measures, such as fuses and relays, to safeguard the electrical system from overloads and short circuits. These safety features help maintain the integrity of the engine’s electrical network, preventing damage to sensitive components and ensuring reliable operation.

Conclusion

The Cummins 4065244 Wiring Harness is a fundamental element in the engine’s electrical system, enabling efficient communication and power distribution between the ECU and various engine modules. Its robust design and protective features contribute to the overall reliability and performance of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.