This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

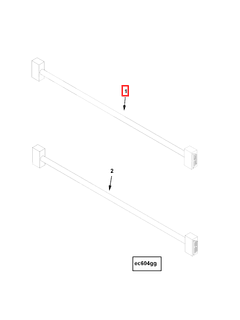

The 4302180 Wiring Harness, manufactured by Cummins, is a critical component in the electrical system of commercial trucks. This part facilitates the efficient and reliable operation of various electrical components, underscoring its importance in commercial truck operations.

Basic Concepts of Wiring Harnesses

A wiring harness is a collection of wires, connectors, and components that transmit electrical power and signals throughout a vehicle. It consists of insulated wires bundled together, often with protective coverings, and includes connectors that link to various electrical components. Within a vehicle’s electrical system, the wiring harness serves as the backbone, enabling communication and power distribution between the battery, engine control unit (ECU), sensors, and other electrical devices 1.

Role of the 4302180 Wiring Harness in Truck Operation

The 4302180 Wiring Harness is designed to connect various electrical components, ensuring they receive the necessary power and signals to function correctly. This harness interacts with the truck’s ECU, sensors, and other electrical systems, facilitating the operation of critical functions such as engine management, lighting, and diagnostic systems 2.

Key Features

The 4302180 Wiring Harness is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. The harness is engineered to withstand the rigors of heavy-duty use, ensuring durability and longevity. Additionally, it features precise connectors and terminals that ensure secure and reliable connections, minimizing the risk of electrical faults 3.

Benefits of Using the 4302180 Wiring Harness

Utilizing the 4302180 Wiring Harness offers several advantages in truck operations. Its robust construction and high-quality materials contribute to improved reliability, reducing the likelihood of electrical failures. The precise design of the harness enhances efficiency by ensuring optimal electrical conductivity and signal transmission. Furthermore, the harness’s durability and resistance to environmental factors contribute to enhanced safety by minimizing the risk of electrical malfunctions that could lead to accidents 4.

Installation Considerations

When installing the 4302180 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. This includes carefully routing the harness to avoid interference with other components and ensuring all connections are secure and correctly aligned. Adhering to manufacturer recommendations and using the appropriate tools and techniques will help achieve a successful installation.

Maintenance and Troubleshooting

Maintaining the 4302180 Wiring Harness involves regular inspections to check for signs of wear, corrosion, or damage. Cleaning the harness and ensuring connections remain secure can help prevent issues. Troubleshooting common problems may involve checking for loose connections, inspecting wires for damage, and using diagnostic tools to identify electrical faults. Following recommended practices for maintenance can contribute to the longevity and performance of the harness.

Compatibility and Applications

The 4302180 Wiring Harness is designed for use in specific types of commercial trucks and engines. It is important to verify compatibility with the truck’s make, model, and engine type to ensure proper fit and function. Cummins provides detailed information on the applications for which this wiring harness is intended, helping users select the correct component for their vehicle.

Safety Considerations

When working with the 4302180 Wiring Harness, it is crucial to observe safety protocols and considerations. This includes ensuring the truck’s electrical system is de-energized before beginning any work to prevent electrical shocks. Using appropriate personal protective equipment (PPE) and following electrical safety practices can help mitigate risks associated with working on vehicle electrical systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, serving a wide array of industries and applications.

Cummins Wiring Harness 4302180 Compatibility with K19, K38, and K50 Engines

The Cummins Wiring Harness part number 4302180 is designed to integrate seamlessly with a range of Cummins engines, including the K19, K38, and K50 models. This wiring harness is a critical component that ensures proper electrical connectivity and communication between various engine systems and components.

For the K19 and K38 engines, the wiring harness 4302180 is engineered to fit snugly within the engine’s electrical architecture. It provides a reliable pathway for electrical signals, ensuring that all sensors, actuators, and control modules are properly connected. This is particularly important for maintaining engine performance, efficiency, and safety.

In the case of the K50 engine, the wiring harness 4302180 is similarly designed to interface with the engine’s electrical system. The K50, being a more recent model, may incorporate advanced technologies and features that require precise wiring configurations. The harness ensures that all these components are correctly wired, facilitating optimal engine operation.

The compatibility of the wiring harness with these engines is a testament to Cummins’ commitment to providing high-quality, reliable parts. This ensures that technicians and mechanics can confidently use the 4302180 wiring harness with the K19, K38, and K50 engines, knowing it will perform as expected.

Role of Part 4302180 Wiring Harness in Engine Systems

The 4302180 Wiring Harness is an integral component in the electrical system of engine setups, facilitating the connection between various electrical components and the engine’s control unit. This harness is designed to streamline the electrical pathways, ensuring efficient and reliable communication and power distribution across the engine system.

Integration with Engine Components

-

Harness Connections: The primary function of the 4302180 Wiring Harness is to establish secure and organized connections between the engine’s electrical components. This includes sensors, actuators, and control modules. By providing a structured pathway for electrical signals, the harness reduces the risk of short circuits and ensures consistent performance of engine functions.

-

Extension Capabilities: In complex engine systems, the wiring harness often includes extension components to reach distant parts of the engine bay. These extensions are vital for connecting components such as the oxygen sensors, throttle position sensors, and fuel injectors, which are typically located in hard-to-reach areas. The extensions maintain signal integrity over longer distances, which is essential for accurate data transmission and reliable engine operation.

-

Wiring Organization: The harness plays a significant role in organizing the myriad of wires within the engine compartment. It bundles multiple wires into a single, manageable unit, which simplifies the installation process and reduces the likelihood of wires becoming tangled or damaged. This organization is particularly important in high-vibration environments, such as those found in engine compartments, where loose wires can lead to intermittent connections or failures.

Enhanced System Reliability

By centralizing and standardizing the electrical connections, the 4302180 Wiring Harness contributes to the overall reliability of the engine system. It allows for easier troubleshooting and maintenance, as technicians can quickly identify and access specific wires or connections. Additionally, the harness is often designed with protective coatings and shielding to withstand the harsh conditions within an engine bay, further enhancing its durability and longevity.

Conclusion

In summary, the 4302180 Wiring Harness is a fundamental component that ensures the seamless integration and operation of various electrical systems within an engine. Its role in maintaining organized, secure, and efficient electrical connections is essential for the optimal performance and reliability of modern engine systems.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.