This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4302181 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety 1.

Basic Concepts of Wiring Harnesses

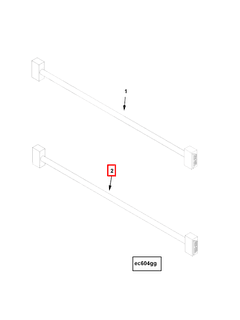

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 2.

Purpose of the 4302181 Wiring Harness

The Cummins 4302181 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects various electrical components, allowing them to communicate and function together. This harness plays a role in ensuring that all electrical systems within the truck operate harmoniously, contributing to the vehicle’s overall efficiency and reliability 3.

Key Features

The 4302181 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions of commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness incorporates features such as protective coatings and durable connectors to enhance its performance and longevity. Additionally, its design allows for easy integration with other systems and components within the truck.

Benefits of Using the 4302181 Wiring Harness

Utilizing the Cummins 4302181 Wiring Harness in commercial trucks offers several advantages. It contributes to improved efficiency by ensuring reliable electrical connections, which can lead to better overall vehicle performance. The harness also enhances reliability by reducing the risk of electrical failures, which can be critical in commercial operations. Furthermore, it plays a role in safety by maintaining stable electrical connections, which is vital for the operation of safety-related systems 4.

Installation and Integration

When installing the Cummins 4302181 Wiring Harness, it is important to follow guidelines to ensure proper integration with the truck’s electrical system. Compatibility with various truck models and systems should be considered to ensure seamless operation. Proper installation involves securing the harness in place, making sure all connections are secure, and testing the system to confirm that all electrical components are functioning correctly.

Maintenance and Troubleshooting

Maintaining the Cummins 4302181 Wiring Harness involves regular inspections to identify any signs of wear or damage. Common issues may include frayed wires or loose connections, which can be addressed through repair or replacement as necessary. Troubleshooting procedures may involve testing electrical connections and using diagnostic tools to identify and resolve any issues that arise.

Safety Considerations

When working with the Cummins 4302181 Wiring Harness, it is important to observe safety protocols to prevent accidents. This includes ensuring that the vehicle is turned off and the electrical system is disconnected before beginning any work. Additionally, using appropriate personal protective equipment and following manufacturer guidelines can help ensure safe operation and maintenance of the wiring harness.

Environmental Impact

The production, use, and disposal of the Cummins 4302181 Wiring Harness have environmental considerations. Efforts to minimize the environmental footprint may include using recyclable materials in its construction and implementing responsible disposal practices. Cummins is committed to reducing the environmental impact of its products through ongoing innovation and sustainability initiatives.

Cummins Overview

Cummins is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and power generation applications, demonstrating its versatility and expertise in the automotive industry.

Compatibility with K19, K38, and K50 Engines

The Cummins Wiring Harness part number 4302181 is designed to integrate seamlessly with various Cummins engines, including the K19, K38, and K50 models. This wiring harness is a component in ensuring the electrical systems of these engines function properly, facilitating communication between different parts of the engine and its control systems.

K19 and K38 Engines

For the K19 and K38 engines, the wiring harness 4302181 is engineered to connect essential electrical components, such as sensors, actuators, and control modules. These engines are often found in heavy-duty applications, where reliable and efficient electrical connections are paramount. The harness ensures that power and data signals are transmitted accurately and without interruption, which is crucial for maintaining engine performance and safety.

K50 Engine

The K50 engine, known for its robust design and high power output, also benefits from the precise electrical connections provided by the Cummins Wiring Harness 4302181. This engine is typically used in demanding environments, such as construction and agricultural machinery, where durability and reliability are key. The wiring harness is designed to withstand the rigors of these environments, ensuring long-term functionality and reducing the risk of electrical failures.

Grouping for Efficiency

When considering the K19, K38, and K50 engines together, it is evident that the wiring harness 4302181 is a versatile component that can be used across multiple engine models. This compatibility allows for streamlined maintenance and repair processes, as technicians can use a single wiring harness for different engine types, reducing inventory costs and simplifying part management. Additionally, the standardized design of the harness ensures that it can be easily integrated into the engine’s electrical architecture, regardless of the specific model.

Role of Part 4302181 Wiring Harness in Engine Systems

The Part 4302181 Wiring Harness is an integral component in the electrical system of engine setups. It serves as the primary conduit for electrical signals and power distribution among various engine components.

Integration with Engine Components

-

Harness: The primary function of the Wiring Harness is to connect the engine’s electrical system to the vehicle’s main electrical system. It ensures that all engine components receive the necessary power and signals to operate correctly.

-

Extension Harness: In scenarios where additional length is required to reach specific components, the Extension Harness works in conjunction with the primary Wiring Harness. This extension allows for greater flexibility in routing and ensures that all parts of the engine, regardless of their position, are adequately powered and signaled.

-

Wiring: The individual wires within the Wiring Harness are responsible for carrying electrical current to and from various engine components. These wires are meticulously organized and protected within the harness to prevent damage and ensure reliable performance.

Functionality in the Electrical System

-

Power Distribution: The Wiring Harness distributes electrical power from the battery to components such as the ignition system, fuel injectors, sensors, and actuators. This ensures that each component receives the correct voltage and current for optimal performance.

-

Signal Transmission: It also facilitates the transmission of signals from sensors (e.g., oxygen sensors, throttle position sensors) to the engine control unit (ECU). These signals are vital for the ECU to make real-time adjustments to the engine’s operation.

-

Grounding: The harness includes grounding wires that connect various components to the vehicle’s chassis. Proper grounding is essential for the efficient operation of electrical systems and for preventing electrical interference.

Enhanced Reliability and Safety

The organized structure of the Wiring Harness reduces the risk of short circuits and electrical fires. It also simplifies the troubleshooting process by providing a clear and accessible pathway for electrical connections.

Conclusion

In summary, the Part 4302181 Wiring Harness plays a significant role in ensuring the reliable and efficient operation of engine systems by providing a structured and protected pathway for electrical power and signals.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5659712, X15 CM2350 X140C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.