This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

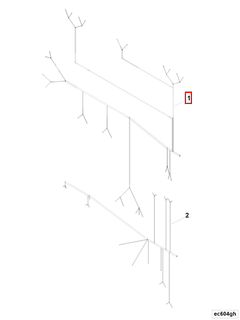

The Cummins 4309881 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital link in the electrical system, facilitating the connection between various electrical components and the truck’s power source. Its role is significant in ensuring the smooth operation of electrical systems within commercial trucks, contributing to overall vehicle performance and reliability 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different components of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 2.

Purpose of the 4309881 Wiring Harness

This Cummins part is engineered to support the electrical needs of commercial trucks. It integrates with the truck’s electrical system, connecting critical components such as sensors, control modules, and lighting systems. This integration allows for the efficient distribution of electrical power and signals, ensuring that all electrical components operate as intended. The harness also plays a role in protecting the wires from physical damage and environmental factors, contributing to the reliability of the truck’s electrical system 3.

Key Features

The 4309881 is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the demanding conditions of commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness features durable connectors and insulation materials that enhance its performance and longevity. Additionally, its design allows for easy integration with the truck’s existing electrical system, facilitating straightforward installation and maintenance.

Benefits

The use of the 4309881 in commercial trucks offers several advantages. It contributes to improved reliability by ensuring stable and efficient electrical connections. This reliability is crucial for the operation of safety-critical systems and can lead to enhanced overall vehicle performance. Furthermore, the harness’s design supports efficient electrical distribution, which can contribute to fuel efficiency and reduced emissions. Safety is also enhanced, as the harness helps prevent electrical faults that could lead to accidents.

Installation and Integration

When installing this part, it is important to follow guidelines to ensure compatibility with the truck’s electrical system. The harness is designed to be compatible with a range of truck models and systems, but careful consideration should be given to the specific electrical requirements of the truck. Proper installation involves securing the harness in place, ensuring all connections are secure, and verifying that the harness does not interfere with other components. It is also important to consult the truck’s manual or a professional technician to ensure the harness is installed correctly.

Troubleshooting and Maintenance

Common issues with the 4309881 may include loose connections, damaged wires, or faulty connectors. Regular inspection and maintenance can help identify these issues early, allowing for timely repairs. Diagnostic procedures may involve testing the electrical continuity of the wires and checking the condition of the connectors. Maintenance tips include keeping the harness clean and dry, avoiding sharp edges that could damage the wires, and ensuring that all connections are tight and secure.

Safety Considerations

When working with the 4309881, it is important to observe safety practices to prevent accidents. This includes disconnecting the battery before beginning any work on the electrical system to avoid the risk of electric shock. It is also important to use the correct tools and follow proper procedures when making connections or repairs. Additionally, ensuring that the harness is installed and maintained according to industry standards helps to ensure compliance with safety regulations and contributes to the overall safety of the vehicle.

Environmental Impact

The production, use, and disposal of the 4309881 have environmental considerations. Cummins Inc. is committed to minimizing the ecological footprint of its products through sustainable manufacturing practices, the use of recyclable materials, and efforts to reduce waste. The company also encourages the recycling of wiring harnesses at the end of their life cycle to reduce environmental impact.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s product portfolio includes a wide range of engines and components for on-highway and off-highway applications, demonstrating its expertise in the automotive industry. Cummins’ dedication to advancing technology and improving the efficiency and reliability of its products underscores its position as a leader in the field.

Cummins Wiring Harness 4309881 Compatibility

The Cummins Wiring Harness 4309881 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connections and optimal performance. This wiring harness is engineered to fit specific engine configurations, providing a robust solution for maintaining the integrity of the electrical system.

K50 Series

For the K50 series engines, the Wiring Harness 4309881 is tailored to meet the unique electrical requirements of these models. It ensures that all necessary components are properly connected, facilitating efficient power distribution and communication between various engine systems. The harness is constructed with high-quality materials to withstand the rigors of engine operation, ensuring durability and longevity.

Integration with Cummins Engines

The Cummins Wiring Harness 4309881 is meticulously designed to interface with the electrical architecture of Cummins engines. This includes compatibility with the K50 series, where it plays a crucial role in managing the flow of electrical signals throughout the engine. The harness is engineered to fit precisely, reducing the risk of loose connections or electrical faults that could compromise engine performance.

Application in Engine Systems

In Cummins engines, the Wiring Harness 4309881 is integral to the overall functionality of the electrical system. It connects critical components such as sensors, actuators, and control modules, ensuring that they operate in harmony. This is particularly important in the K50 series, where precise electrical management is essential for maintaining engine efficiency and reliability.

Ensuring Compatibility and Performance

When installing the Cummins Wiring Harness 4309881 in K50 engines, it is essential to follow the manufacturer’s guidelines to ensure proper fitment and function. The harness is designed to be a direct replacement for the original equipment, providing a hassle-free installation process. Its compatibility with the K50 series ensures that the engine’s electrical system operates smoothly, contributing to overall performance and longevity.

Role of Part 4309881 Wiring Harness in Engine Systems

The wiring harness, part 4309881, is an integral component in the orchestration of various engine systems. It serves as the central nervous system, facilitating communication and power distribution among the engine’s electronic control unit (ECU), sensors, actuators, and other electrical components.

Integration with Engine Systems

-

Electronic Control Unit (ECU): The wiring harness connects the ECU to all other electrical components, allowing it to monitor and control engine operations. This includes adjusting fuel injection, ignition timing, and other parameters to optimize performance and efficiency.

-

Sensors: Various sensors, such as the oxygen sensor, mass airflow sensor, and crankshaft position sensor, rely on the wiring harness to transmit data to the ECU. This data is essential for the ECU to make real-time adjustments to engine operations.

-

Actuators: Components like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids are controlled by the ECU via the wiring harness. These actuators adjust engine parameters based on the data received from sensors.

-

Ignition System: The wiring harness routes power to the ignition coils and spark plugs. It ensures that the ignition system fires at the correct time, contributing to efficient combustion and engine performance.

-

Fuel System: It connects the fuel pump, fuel pressure regulator, and fuel injectors, ensuring that the fuel system operates within specified parameters for optimal engine performance.

-

Emission Control Systems: Components like the catalytic converter, EGR valve, and EVAP system are also interconnected via the wiring harness. This ensures that emission control systems function correctly, reducing harmful emissions.

-

Battery and Charging System: The wiring harness links the battery to the alternator and other electrical components, ensuring a consistent power supply to the engine systems.

-

Lighting and Instrumentation: Although not directly related to engine performance, the wiring harness also connects lighting and instrumentation systems, providing essential feedback to the driver.

In summary, the wiring harness, part 4309881, plays a significant role in the seamless operation of various engine systems. Its proper functioning is essential for the engine to operate efficiently and effectively.

Conclusion

The Cummins 4309881 Wiring Harness is a critical component in the electrical systems of commercial trucks and Cummins engines. Its robust design, compatibility with various engine models, and integral role in engine systems make it essential for maintaining vehicle performance and reliability. Proper installation, maintenance, and adherence to safety practices are crucial for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.