This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4330273 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital element in the electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures the efficient and reliable operation of the truck’s electrical systems, contributing to overall vehicle performance and safety 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring consistent electrical performance. Within a vehicle’s electrical system, the wiring harness provides a structured pathway for electricity to flow between components, enabling the operation of lights, sensors, and other electrical devices 2.

Purpose of the 4330273 Wiring Harness

The Cummins 4330273 Wiring Harness is specifically engineered to integrate with the electrical systems of commercial trucks. It connects various components such as sensors, lights, and control modules, ensuring they receive the necessary power and signals to function correctly. This harness is designed to work in conjunction with the truck’s engine, transmission, and other systems, contributing to the overall efficiency and reliability of the vehicle 3.

Key Features

The 4330273 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear, corrosion, and environmental factors. The harness is also designed with flexibility in mind, allowing it to be routed through the truck’s chassis without compromising its integrity. Additionally, it features color-coded wires and connectors for easy identification and installation.

Benefits

The use of the Cummins 4330273 Wiring Harness offers several advantages in truck operations. It enhances the efficiency of the electrical system by providing a reliable and organized pathway for electricity. This results in improved performance of electrical components and reduced risk of electrical failures. Additionally, the harness contributes to the safety of the truck by ensuring that all electrical connections are secure and properly insulated, minimizing the risk of short circuits and electrical fires.

Installation Process

Installing the Cummins 4330273 Wiring Harness requires careful attention to detail to ensure proper function and safety. The process involves routing the harness through the truck’s chassis, connecting it to the appropriate electrical components, and securing it in place. It is important to follow the manufacturer’s instructions and use the recommended tools and techniques to avoid damaging the harness or the vehicle’s electrical system. Regular inspections and maintenance can help identify and address any issues before they lead to more significant problems.

Troubleshooting and Maintenance

Common issues with the 4330273 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Regular inspections can help identify these problems early, allowing for timely repairs or replacements. Maintenance practices such as cleaning the harness and ensuring all connections are secure can contribute to its longevity and optimal performance. It is also important to protect the harness from physical damage and environmental factors that could compromise its integrity.

Safety Considerations

When working with the Cummins 4330273 Wiring Harness, it is important to observe safety protocols to prevent accidents and ensure compliance with industry standards. This includes wearing appropriate personal protective equipment, ensuring the vehicle’s battery is disconnected before beginning work, and following proper handling and installation procedures. Additionally, it is crucial to be aware of the potential risks associated with electrical work, such as electric shock and fire hazards, and take steps to mitigate these risks.

Environmental Impact

The production, use, and disposal of the Cummins 4330273 Wiring Harness have environmental considerations. Efforts to minimize the ecological footprint of the harness include using recyclable materials in its construction and designing it for longevity to reduce the need for frequent replacements. Cummins Inc. is committed to sustainability and continuously seeks ways to improve the environmental performance of its products.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality, innovative solutions for the automotive industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins is dedicated to advancing technology and improving the efficiency and reliability of its products.

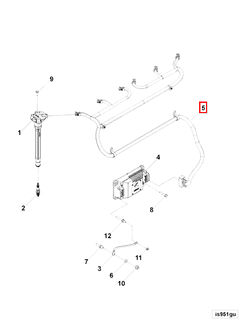

Role of Part 4330273 Wiring Harness in the Ignition System

The part 4330273 Wiring Harness is an essential component in the ignition system, facilitating the electrical connections necessary for the system’s operation. It acts as the conduit for transmitting electrical signals and power from the battery to various ignition components.

Integration with Ignition Components

-

Battery to Ignition Coil: The wiring harness connects the battery’s positive terminal to the ignition coil. This ensures a consistent and reliable power supply, allowing the ignition coil to generate the high voltage needed for spark plug ignition.

-

Ignition Coil to Distributor: In systems equipped with a distributor, the wiring harness links the ignition coil to the distributor. This connection is vital for timing the spark delivery to each cylinder, ensuring efficient combustion.

-

Distributor to Spark Plugs: The harness extends from the distributor to each spark plug, providing the high-voltage current required to ignite the air-fuel mixture within the cylinders. Proper wiring ensures that each spark plug fires at the correct moment in the engine’s cycle.

-

Ignition Control Module: In systems with an ignition control module (ICM), the wiring harness connects the ICM to the ignition coil and other related sensors. This allows the ICM to regulate the timing and intensity of the spark, optimizing engine performance and fuel efficiency.

-

Sensor Connections: The harness also interfaces with various sensors, such as the crankshaft position sensor and camshaft position sensor. These sensors provide feedback to the engine control unit (ECU), allowing for precise ignition timing adjustments based on engine speed and load conditions.

-

Grounding: Effective grounding is achieved through the wiring harness, which connects critical components to the vehicle’s chassis. This ensures a stable electrical environment, reducing the risk of electrical noise and improving overall system reliability.

By meticulously routing and securing these connections, the part 4330273 Wiring Harness plays a significant role in maintaining the integrity and efficiency of the ignition system, ultimately contributing to the engine’s smooth operation.

Conclusion

The Cummins 4330273 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient and reliable operation of various electrical components. Its robust design, high-quality materials, and meticulous integration with ignition systems contribute to the overall performance and safety of the vehicle. Regular maintenance and adherence to safety protocols are essential for maximizing the lifespan and effectiveness of this Cummins part.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7N CM2380 B150B. Bulletin Number 5467666.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.