This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4930106 Wiring Harness, manufactured by Cummins, is a vital component in the electrical system of commercial trucks. Cummins, a well-established name in the commercial truck industry, is known for its high-quality and reliable parts. This part is designed to facilitate the efficient and safe transmission of electrical power throughout the truck, ensuring that all electrical components function correctly.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals between various components of a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, ensuring that power reaches its intended destinations efficiently and safely 1.

Purpose of the 4930106 Wiring Harness

This Cummins part is integral to the operation of a commercial truck. It connects various electrical components and systems, such as the engine control module, sensors, lights, and other electronic devices. By providing a reliable pathway for electrical signals and power, the harness ensures that these components can communicate and function as intended. Its design allows for seamless integration with the truck’s existing electrical architecture, enhancing overall system performance 2.

Key Features

The 4930106 Wiring Harness is characterized by several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The design includes robust connectors and terminals that ensure secure and stable connections. Additionally, the harness is engineered to withstand the vibrations and harsh conditions typical of commercial truck operations, ensuring long-lasting reliability 3.

Benefits

This part offers several benefits that contribute to the efficiency, reliability, and safety of truck operations. Improved electrical efficiency is achieved through the organized and direct routing of wires, reducing the risk of shorts and ensuring consistent power delivery. The reliability of the harness is enhanced by its durable construction and resistance to environmental factors. Safety is also a significant benefit, as the harness is designed to minimize the risk of electrical faults and fires, protecting both the vehicle and its occupants 4.

Installation Considerations

When installing the 4930106 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration and functionality. Preparatory steps include ensuring that the truck’s electrical system is clean and free of debris. The necessary tools, such as wire strippers, crimping tools, and multimeters, should be on hand. Common pitfalls to avoid include improper wire routing, which can lead to damage or interference, and insufficient securing of connections, which can result in loose or faulty connections 5.

Troubleshooting Common Issues

Common problems associated with wiring harnesses can include loose connections, damaged wires, and faulty terminals. To troubleshoot these issues, begin by inspecting the harness for any visible signs of damage or wear. Use a multimeter to test for continuity and identify any breaks in the wiring. If a problem is detected, carefully repair or replace the affected section, ensuring that all connections are secure and properly insulated 6.

Maintenance Tips

Regular maintenance of the 4930106 Wiring Harness is essential to ensure its longevity and optimal performance. Inspection routines should include checking for signs of wear, corrosion, or damage to the wires and connectors. Cleaning procedures involve removing any dirt or debris that may have accumulated on the harness, ensuring that all connections remain clean and dry. Periodically testing the electrical system for proper function can also help identify potential issues before they become serious problems 7.

Safety Precautions

When working with the 4930106 Wiring Harness, it is important to observe several safety measures. Electrical safety practices include ensuring that the truck’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Handling guidelines involve using appropriate tools and protective equipment, such as insulated gloves and safety glasses, to protect against potential hazards 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and innovative products. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial truck operators 9.

Cummins Wiring Harness 4930106 Compatibility

The Cummins Wiring Harness 4930106 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the specific needs of Cummins engines, providing a robust and efficient solution for managing electrical systems.

K38 Engine Series

The K38 engine series benefits from the precise design of the 4930106 wiring harness. This harness is tailored to fit the intricate electrical architecture of the K38 engines, ensuring that all necessary connections are made without compromising on performance or reliability. The harness is constructed with high-quality materials that can withstand the rigors of engine operation, providing a durable and long-lasting solution.

Grouping of Compatible Engines

The 4930106 wiring harness is not limited to the K38 series alone. It is also compatible with other Cummins engines that share similar electrical requirements and configurations. This includes:

- K19 Series: The harness is designed to fit the K19 engines, ensuring that all electrical connections are made efficiently and securely.

- QSK Series: For the QSK engines, the 4930106 wiring harness provides a comprehensive solution for managing electrical systems, ensuring optimal performance and reliability.

- C15 Series: The harness is also compatible with the C15 engines, providing a reliable and efficient way to manage electrical connections.

By offering compatibility across multiple engine series, the 4930106 wiring harness provides a versatile solution for Cummins engine users, ensuring that their electrical systems are managed effectively and reliably.

Role of Part 4930106 Wiring Harness in Engine Systems

The 4930106 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various elements.

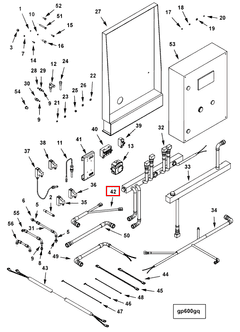

Integration with the Panel

The wiring harness interfaces directly with the panel, which serves as the central hub for electrical connections. This integration ensures that all electrical signals and power requirements are efficiently routed to and from the panel, maintaining the integrity of the electrical system.

Connection to Engine Instruments

Engine instruments rely on accurate and timely data to function correctly. The 4930106 Wiring Harness plays a key role in this by providing a reliable pathway for signals from sensors and other data sources to reach the instruments. This ensures that readings such as temperature, pressure, and RPM are accurately displayed and monitored.

Role in the Wiring Top-Level Assembly Harness

As part of the wiring top-level assembly harness, the 4930106 Wiring Harness contributes to the overall structure and organization of the engine’s electrical system. It helps in maintaining a neat and manageable layout, reducing the risk of electrical interference and improving the system’s reliability.

By efficiently connecting these components, the 4930106 Wiring Harness ensures that the engine system operates smoothly, with all electrical components working in harmony to support the engine’s performance and functionality.

Conclusion

The 4930106 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring efficient and safe transmission of electrical power. Its high-quality construction, compatibility with various Cummins engine models, and essential role in engine systems make it a reliable and indispensable part for truck operators.

-

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Cummins Inc. (n.d.). Service Manual (4367376). Cummins Inc.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Service Manual (4367376). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (4367376). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Company Overview. Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.