This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

A wiring harness is a collection of wires, connectors, and conduits that transmit electrical power and signals between various components of a vehicle. It consists of several basic components, including wires, connectors, terminals, and protective sheathing. The primary role of a wiring harness in automotive systems is to facilitate the efficient and reliable distribution of electrical power and signals, ensuring that all electrical components function correctly. Within the electrical system of a vehicle, the wiring harness acts as the central nervous system, connecting the battery, sensors, control modules, and other electrical devices 1.

Purpose of the 4930108 Wiring Harness

The 4930108 Wiring Harness by Cummins is designed specifically for use in commercial trucks. It plays a significant role in the operation of these vehicles by providing a structured and organized method for routing electrical connections. This harness integrates with various electrical components and systems, such as the engine control module (ECM), sensors, and actuators, ensuring that they receive the necessary power and signals to function correctly. By centralizing these connections, the 4930108 Wiring Harness helps maintain a tidy and manageable electrical system, reducing the risk of wiring errors and improving overall system reliability 2.

Key Features of the 4930108 Wiring Harness

The 4930108 Wiring Harness boasts several key features that enhance its performance and durability. It is constructed using high-quality materials, including robust wires and durable connectors, designed to withstand the harsh conditions often encountered in commercial trucking. The harness is meticulously designed to ensure optimal routing of wires, minimizing the risk of chafing and abrasion. Additionally, it incorporates protective sheathing to guard against environmental factors such as moisture, dirt, and extreme temperatures. These design elements contribute to the harness’s longevity and reliability in demanding applications 3.

Benefits of Using the 4930108 Wiring Harness

Utilizing the 4930108 Wiring Harness offers several advantages. One of the primary benefits is improved electrical efficiency, as the harness ensures that power and signals are transmitted with minimal loss. This results in more reliable operation of electrical components and systems. Additionally, the structured design of the harness reduces the risk of short circuits and other electrical faults, enhancing overall system safety. The durable construction of the 4930108 Wiring Harness also ensures that it can withstand the rigors of commercial trucking, providing long-lasting performance even in harsh operating conditions.

Installation and Integration

Proper installation of the 4930108 Wiring Harness is crucial for ensuring its effective operation within a commercial truck’s electrical system. When installing the harness, it is important to follow the manufacturer’s guidelines to ensure that all connections are secure and correctly routed. The harness should be integrated with the existing electrical systems in a manner that maintains the integrity of the overall system. This may involve connecting the harness to the battery, ECM, sensors, and other components, ensuring that all connections are tight and free from corrosion. Careful planning and execution during installation will help prevent future electrical issues and ensure the harness functions as intended.

Troubleshooting Common Issues

Wiring harnesses, including the 4930108 Wiring Harness, may encounter common problems such as loose connections, damaged wires, or faulty connectors. Troubleshooting these issues involves a systematic approach to identifying and resolving the problem. Begin by visually inspecting the harness for any signs of damage or wear. Check all connections to ensure they are secure and free from corrosion. If an issue is detected, such as a loose connection or damaged wire, it should be addressed promptly to prevent further complications. Using a multimeter to test for continuity and proper voltage can help diagnose electrical issues related to the harness.

Maintenance Tips

Regular maintenance of the 4930108 Wiring Harness is essential for ensuring its longevity and optimal performance. Inspect the harness periodically for signs of wear, damage, or corrosion. Clean the harness and its connections to remove any dirt or debris that may accumulate over time. Ensure that all connections remain tight and secure, and address any issues promptly to prevent them from escalating. By following these maintenance tips, the 4930108 Wiring Harness can continue to provide reliable electrical performance in commercial trucking applications.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a strong reputation in the automotive and heavy-duty truck industries. The company has a long history of innovation and commitment to quality, producing a wide range of components and systems designed to enhance the performance and reliability of vehicles. Cummins is known for its dedication to research and development, ensuring that its products meet the highest standards of quality and durability. This commitment to excellence is reflected in the 4930108 Wiring Harness, which is engineered to provide superior electrical performance and reliability in commercial trucking applications.

Cummins Wiring Harness 4930108 Compatibility with K38 and K50 Engines

The Cummins Wiring Harness part number 4930108 is designed to integrate seamlessly with specific engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to fit the K38 and K50 engines, providing a critical link between various electrical components and the engine control unit (ECU).

For the K38 engine, the wiring harness 4930108 is meticulously crafted to match the engine’s electrical architecture. It ensures that all necessary sensors, actuators, and control modules are properly connected, facilitating efficient engine operation and diagnostics. The harness is designed to withstand the operational stresses of the K38 engine, including temperature variations and vibrations, ensuring durability and reliability.

Similarly, the K50 engine benefits from the precise fit and robust construction of the 4930108 wiring harness. This harness is tailored to the K50’s specific electrical requirements, ensuring that all components are correctly interfaced. The harness’s design allows for easy installation and maintenance, reducing downtime and enhancing overall engine performance.

Both the K38 and K50 engines rely on the 4930108 wiring harness to maintain a stable and efficient electrical system. This part is a critical component in the engine’s electrical infrastructure, ensuring that all systems operate in harmony. The harness’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, reliable parts that meet the demands of modern engine technology.

Role of Part 4930108 Wiring Harness in Engine Systems

The 4930108 Wiring Harness is an integral component that facilitates the electrical connections within various engine systems. Its primary function is to ensure seamless communication and power distribution among different parts of the engine.

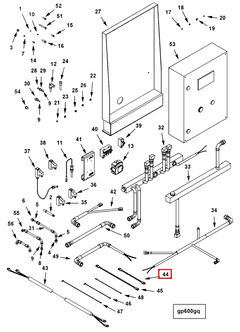

Integration with the Panel

The wiring harness interfaces directly with the panel, which serves as the central hub for monitoring and controlling various engine parameters. By connecting to the panel, the harness allows for the transmission of data and power to and from the engine’s electronic control unit (ECU), ensuring that all readings and commands are accurately relayed.

Connection to the Engine Instrument

The engine instrument relies on the 4930108 Wiring Harness to receive real-time data from sensors distributed throughout the engine. This data includes metrics such as temperature, pressure, and RPM. The harness ensures that these readings are consistently and reliably transmitted to the instrument, enabling precise monitoring and diagnostics.

Role in the Wiring Top Level Assembly Harness

As part of the wiring top level assembly harness, the 4930108 Wiring Harness plays a key role in organizing and routing electrical connections. It acts as a central conduit that links various subsystems, including the fuel injection system, ignition system, and emission control system. This organized routing minimizes the risk of electrical interference and ensures that each subsystem operates efficiently.

Conclusion

In summary, the 4930108 Wiring Harness is essential for maintaining the integrity and functionality of the electrical systems within engine components. Its reliable performance ensures that all interconnected systems work harmoniously, contributing to the overall efficiency and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.