This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4930113 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable and efficient operation of the truck’s electrical systems, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power from the battery to various electrical components, such as lights, sensors, and control units, ensuring they operate correctly 1.

Role of the 4930113 Wiring Harness in Truck Operation

This Cummins part is specifically designed to integrate into the electrical system of commercial trucks, providing connections for sensors, control modules, and other electrical components. It plays a role in facilitating communication between the truck’s engine control unit (ECU) and various sensors, allowing for precise monitoring and control of engine performance. Additionally, it ensures that electrical power is efficiently distributed to components such as lights, gauges, and auxiliary systems, contributing to the truck’s overall operational efficiency 2.

Key Features of the 4930113 Wiring Harness

The 4930113 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable, weather-resistant materials to withstand the harsh conditions often encountered in commercial truck operations. The harness features precise wire gauges and connectors tailored to the specific electrical requirements of the truck, ensuring reliable performance. Additionally, it may include unique characteristics such as integrated fuses or surge protectors to enhance safety and protect sensitive electronic components 3.

Benefits of Using the 4930113 Wiring Harness

Utilizing this part offers several advantages in truck operations. Its design contributes to improved reliability by ensuring secure and consistent electrical connections. The harness enhances efficiency by optimizing the distribution of electrical power throughout the truck’s systems. Furthermore, it plays a role in enhancing safety by incorporating protective features that guard against electrical faults and reduce the risk of component failure 4.

Installation Considerations

Proper installation of the 4930113 Wiring Harness is crucial to ensure its effective operation. Installation guidelines typically recommend following the manufacturer’s instructions carefully, ensuring all connections are secure and properly routed to avoid interference with other components. Special tools may be required for certain connections, and it is important to verify that the harness is compatible with the specific truck model to ensure optimal performance.

Troubleshooting Common Issues

When encountering issues with the 4930113 Wiring Harness, a systematic approach to troubleshooting is recommended. This may involve checking for loose connections, inspecting wires for damage, and testing electrical continuity. Diagnostic tools such as multimeters can be used to identify faults in the harness or connected components. Addressing issues promptly can help prevent further complications and ensure the continued reliable operation of the truck’s electrical system.

Maintenance Tips

Regular maintenance of the 4930113 Wiring Harness is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning connectors to remove dirt or corrosion, and verifying that all connections remain secure. Following a maintenance schedule recommended by the manufacturer can help identify potential issues before they lead to more significant problems.

Safety Precautions

When working with the 4930113 Wiring Harness, it is important to observe electrical safety practices. This includes disconnecting the battery before beginning any work to prevent electrical shock or short circuits. Additionally, using insulated tools and wearing appropriate personal protective equipment (PPE) can help protect against injury. Handling the harness with care, avoiding sharp edges or excessive force, is also important to prevent damage to the wires or connectors.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the diverse needs of its customers, contributing to the efficiency and performance of commercial vehicles worldwide.

Cummins Wiring Harness 4930113 Compatibility with K38 and K50 Engines

The Cummins Wiring Harness 4930113 is designed to integrate seamlessly with the K38 and K50 engine series. This wiring harness is a component in ensuring the electrical systems of these engines function properly.

For the K38 engine, the harness is engineered to connect various electrical components, facilitating the transmission of power and signals throughout the engine system. The harness is meticulously routed to avoid interference with moving parts and is secured in a manner that withstands the vibrations and stresses typical of engine operation.

In the K50 engine, the 4930113 wiring harness is similarly essential. It provides a reliable pathway for electrical connections, ensuring that all sensors, actuators, and control units communicate effectively. The harness is designed to be durable, with high-quality materials that resist wear and corrosion, which is crucial for maintaining engine performance over time.

Both engines benefit from the precise engineering of this wiring harness, which ensures compatibility and ease of installation. The harness is crafted to fit snugly and securely, minimizing the risk of disconnections or damage due to movement. This reliability is critical for the overall efficiency and longevity of the engines.

Role of Part 4930113 Wiring Harness in Engine Systems

The 4930113 Wiring Harness is an integral component that facilitates the seamless integration and operation of various engine systems. It serves as the vital link between the electrical and electronic components within the engine compartment, ensuring efficient communication and power distribution.

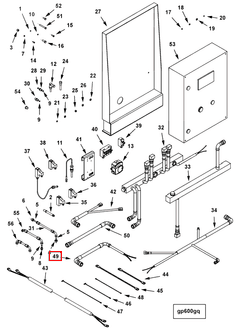

Integration with the Panel

The wiring harness connects to the panel, which houses multiple control modules and sensors. This connection allows for the transmission of data and power to and from the panel, enabling it to monitor and regulate engine performance. The harness ensures that all signals from the panel are accurately relayed to the engine’s electronic control unit (ECU), allowing for precise control over engine functions.

Connection to Engine Instruments

Engine instruments, such as gauges and sensors, rely on the 4930113 Wiring Harness to transmit real-time data to the ECU. This data includes metrics like engine temperature, oil pressure, and fuel levels. The harness ensures that these instruments are accurately powered and that their readings are consistently communicated to the ECU, allowing for optimal engine management and diagnostics.

Role in the Wiring Top-Level Assembly Harness

As part of the wiring top-level assembly harness, the 4930113 Wiring Harness plays a key role in organizing and routing wires throughout the engine compartment. It helps maintain a tidy and efficient wiring layout, reducing the risk of electrical interference and ensuring that all connections are secure and reliable. This organization is essential for the overall functionality and safety of the engine system.

Conclusion

In summary, the 4930113 Wiring Harness is essential for the proper functioning of engine systems. It ensures that all components—from the panel to the engine instruments and the top-level wiring assembly—are interconnected and operate harmoniously. This integration is fundamental for the engine’s performance, efficiency, and reliability.

-

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.