This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

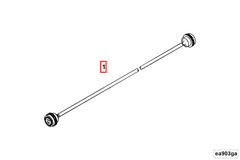

The Cummins 4939807 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It consists of insulated wires bundled together and often includes connectors, terminals, and protective sheathing. The primary function of a wiring harness is to organize and protect the electrical cables, ensuring efficient and safe transmission of power and data within the vehicle’s electrical system 1.

Purpose of the 4939807 Wiring Harness

The Cummins 4939807 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It plays a role in connecting various electrical components, such as sensors, lights, and control modules, to the truck’s power source. This integration ensures that all electrical systems operate harmoniously, contributing to the truck’s overall functionality and performance 2.

Key Features

The 4939807 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable insulation and corrosion-resistant connectors to withstand the harsh conditions often encountered in commercial truck operations. Additionally, the harness is designed with flexibility and ease of installation in mind, featuring pre-assembled connectors and terminals that simplify the integration process 3.

Benefits

The use of the 4939807 Wiring Harness offers several advantages in truck operations. It enhances the reliability of the electrical system by providing secure and durable connections. The harness also contributes to improved efficiency, as it reduces the risk of electrical faults and ensures consistent power delivery to all connected components. Furthermore, by maintaining the integrity of the electrical system, the harness plays a role in enhancing the safety of truck operations 4.

Installation Process

Installing the 4939807 Wiring Harness requires careful attention to detail to ensure proper setup. The process involves identifying the correct routing paths for the harness within the truck, securing it in place using appropriate fasteners, and connecting it to the vehicle’s electrical system. Tools such as wire strippers, crimping tools, and a multimeter may be required. It is important to follow the manufacturer’s instructions closely to ensure correct installation 5.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, or faulty connectors. To address these problems, it is important to conduct a thorough inspection of the harness, checking for signs of wear, corrosion, or damage. Diagnostic tools such as a multimeter can help identify electrical faults. Repair strategies may involve replacing damaged sections of the harness, tightening loose connections, or using electrical tape to insulate exposed wires 6.

Maintenance Tips

Regular maintenance of the 4939807 Wiring Harness is key to prolonging its lifespan and ensuring reliable operation. This includes periodic inspections for signs of wear or damage, cleaning the harness to remove dirt and debris, and ensuring all connections are secure. Preventive measures such as applying dielectric grease to connectors can help protect against corrosion and ensure a stable electrical connection 7.

Safety Considerations

When working with the 4939807 Wiring Harness, it is important to observe safety protocols to protect both mechanics and operators. This includes wearing appropriate personal protective equipment, ensuring the truck’s battery is disconnected before beginning work, and following all manufacturer guidelines for handling and installation. Awareness of the electrical system’s layout and potential hazards is crucial for safe maintenance and repair practices 8.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement have established it as a trusted name in the industry 9.

Compatibility with Engine Models

This Cummins part is designed to integrate seamlessly with a range of Cummins engine models, ensuring reliable electrical connectivity and performance. This wiring harness is compatible with the following engines:

- QSB5.9 CM850

- QSB6.7 M CM2250

- QSC8.3 CM850 (CM2850)

- QSM11 CM570

For the QSB5.9 CM850 and QSB6.7 M CM2250, the wiring harness 4939807 provides electrical connections that support the engine’s operation, ensuring that all necessary components receive power and signals accurately. This compatibility is crucial for maintaining the engine’s performance and reliability.

The QSC8.3 CM850 (CM2850) also benefits from the 4939807 wiring harness, which is engineered to handle the higher power demands and complex electrical systems of this engine model. The harness ensures that all electrical components are properly connected and functioning, which is vital for the engine’s overall efficiency and longevity.

Similarly, the QSM11 CM570 engine is designed to work with the 4939807 wiring harness. This harness is tailored to meet the specific electrical requirements of the QSM11 model, ensuring that all systems are interconnected and operating as intended.

By using the Cummins Wiring Harness 4939807, operators can be confident that their engines will have the necessary electrical infrastructure to perform optimally. This compatibility across multiple engine models highlights the versatility and reliability of Cummins’ design and engineering 10.

Role of 4939807 Wiring Harness in Engine Systems

This part is an integral component that facilitates the electrical connectivity within various engine systems. It serves as a conduit for electrical signals and power, ensuring seamless operation and communication between different parts of the engine.

Integration with the Alternate Station Harness

In systems utilizing an Alternate Station Harness, the 4939807 Wiring Harness plays a significant role. It connects the alternate station components to the primary electrical system, allowing for the distribution of power and signals necessary for the operation of secondary control stations. This ensures that all stations have access to essential engine data and controls, enhancing operational flexibility and redundancy.

Functionality in the Main Extension Harness

When integrated with the Main Extension Harness, the 4939807 Wiring Harness extends the reach of the primary electrical system to additional components and subsystems. This extension is vital for engines with complex layouts or those requiring additional sensors and actuators. The wiring harness ensures that these extended components receive the necessary power and signals, maintaining the engine’s overall performance and reliability.

Contribution to the Secondary Instrument Panel Harness

In conjunction with the Secondary Instrument Panel Harness, the 4939807 Wiring Harness provides the necessary connections for auxiliary instruments and displays. This integration allows for the monitoring of various engine parameters from a secondary location, which is particularly useful in large or multi-engine systems. The wiring harness ensures that all instruments receive accurate and timely data, contributing to effective engine management and diagnostics.

Conclusion

The Cummins 4939807 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring reliable connectivity and performance across various engine models. Its robust design, compatibility with multiple engine types, and role in enhancing engine efficiency and safety make it an essential part for truck operators and maintenance professionals.

-

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2350 X144C. Bulletin Number 5659743.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2350 X144C. Bulletin Number 5659743.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2350 X144C. Bulletin Number 5659743.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Owners Manual for X12 CM2350 X144C. Bulletin Number 5659743.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.