This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

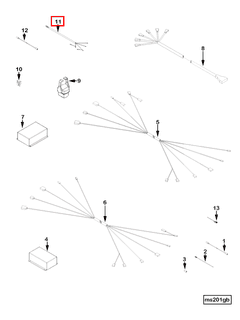

The 4946018 Wiring Loom, manufactured by Cummins, is a specialized component designed for use in commercial truck operations. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this wiring loom to meet the demanding requirements of commercial vehicles. This Cummins part is integral to the electrical system of these trucks, ensuring reliable and efficient operation.

Basic Concepts of Wiring Looms

A wiring loom is an organized assembly of wires and cables bundled together to facilitate the transmission of electrical signals and power within a vehicle. It consists of various components, including individual wires, connectors, and protective sheathing. The primary function of a wiring loom is to manage and protect the electrical connections throughout the vehicle, ensuring that power is distributed efficiently and safely to all electrical components 1.

Purpose of the 4946018 Wiring Loom

The 4946018 Wiring Loom is specifically designed to play a role in the electrical system of commercial trucks by providing a structured and protected pathway for electrical signals and power. It integrates with other electrical components and systems, such as the engine control unit (ECU), sensors, and various truck accessories, ensuring seamless communication and operation. This wiring loom helps in maintaining the integrity of the electrical connections, even under the harsh conditions typically encountered in commercial truck operations 2.

Key Features

The 4946018 Wiring Loom is characterized by its robust design and the high-quality materials used in its construction. It features durable insulation and protective sheathing to safeguard the wires from physical damage, moisture, and extreme temperatures. The loom is engineered to withstand the vibrations and mechanical stresses inherent in heavy-duty truck applications. Additionally, its design allows for easy integration with existing electrical systems, facilitating both new installations and replacements 3.

Benefits

The 4946018 Wiring Loom offers several advantages, including enhanced electrical efficiency, reduced risk of short circuits, and improved reliability in demanding operating conditions. By providing a well-organized and protected pathway for electrical signals, it helps in minimizing energy loss and ensuring consistent performance. The robust construction of the loom also contributes to its longevity, reducing the need for frequent replacements and maintenance.

Installation and Integration

Proper installation and integration of the 4946018 Wiring Loom are vital for ensuring its effective performance. It is important to follow manufacturer guidelines to ensure that the loom is correctly routed and secured within the truck’s chassis. Careful attention should be paid to maintaining the integrity of the protective sheathing and ensuring that all connections are secure and properly insulated. Integration with the truck’s existing electrical system requires precise alignment and connection to avoid any disruptions in the electrical flow.

Troubleshooting and Maintenance

Common issues with wiring looms may include wear and tear, exposure to moisture, or physical damage. Regular inspections can help in identifying potential problems early. Maintenance practices such as checking for frayed wires, ensuring proper insulation, and verifying secure connections can help in maintaining the optimal performance of the 4946018 Wiring Loom. If issues are detected, it is important to address them promptly to prevent more significant electrical problems.

Safety Considerations

When working with the 4946018 Wiring Loom, it is important to observe electrical safety protocols. This includes ensuring that the vehicle’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Additionally, proper handling and storage of the wiring loom are necessary to maintain its integrity. Using appropriate personal protective equipment (PPE) and following Cummins’ guidelines for electrical work can further enhance safety.

Environmental Impact

The production, use, and disposal of the 4946018 Wiring Loom have environmental considerations. Cummins is committed to minimizing its ecological footprint through various initiatives, including the use of recyclable materials and adherence to environmentally friendly manufacturing processes. Proper disposal and recycling of the wiring loom at the end of its lifecycle can also contribute to reducing its environmental impact.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of commercial applications.

Cummins Engine Wiring Loom 4946018 Compatibility

The Cummins Wiring Loom part number 4946018 is designed to be compatible with a range of Cummins engines, ensuring seamless integration and reliable electrical connections. This wiring loom is specifically engineered to fit the following engines:

QSB5.9 CM850

The QSB5.9 CM850 engine benefits from the 4946018 wiring loom, which provides a robust and efficient electrical connection system. This ensures that the engine’s electrical components operate smoothly, enhancing overall performance and reliability.

QSB6.7 M CM2250

Similarly, the QSB6.7 M CM2250 engine is equipped with the 4946018 wiring loom, which is tailored to meet the specific electrical needs of this engine model. This compatibility ensures that the engine’s electrical systems are well-protected and efficiently managed.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine also utilizes the 4946018 wiring loom. This part is designed to handle the higher electrical demands of this engine, providing a reliable and durable solution for maintaining the engine’s electrical integrity.

QSM11 CM570

Lastly, the QSM11 CM570 engine is another model that is compatible with the 4946018 wiring loom. This compatibility ensures that the engine’s electrical systems are well-supported, contributing to the engine’s overall performance and longevity.

By ensuring compatibility with these specific engine models, the Cummins Wiring Loom part number 4946018 provides a reliable and efficient solution for managing the electrical needs of these engines.

Role of Part 4946018 Wiring Loom in Engine Systems

The 4946018 Wiring Loom is an integral component in the electrical system of engine setups, facilitating seamless communication and power distribution between various engine components.

In coordination with the Control Unit, the 4946018 Wiring Loom ensures that all electrical signals are accurately transmitted. This allows the Control Unit to effectively manage engine operations, including fuel injection timing, ignition timing, and other vital parameters. The loom’s robust design ensures that these signals are delivered without interference, maintaining the precision required for optimal engine performance.

When it comes to the Electrical Throttle Lever, the 4946018 Wiring Loom plays a significant role in translating driver inputs into actionable commands for the engine. It provides a reliable pathway for the electrical signals from the throttle lever to reach the Control Unit. This ensures that the engine responds promptly and accurately to changes in throttle position, contributing to a smooth and responsive driving experience.

Overall, the 4946018 Wiring Loom is essential for maintaining the integrity and efficiency of the engine’s electrical system, ensuring that all components work in harmony to deliver peak performance.

Conclusion

The 4946018 Wiring Loom by Cummins is a critical component in the electrical systems of commercial trucks, designed to ensure reliable and efficient operation under demanding conditions. Its robust design, compatibility with various Cummins engines, and role in maintaining the integrity of electrical connections make it an indispensable part for heavy-duty truck applications. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the performance and longevity of this wiring loom.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.