This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

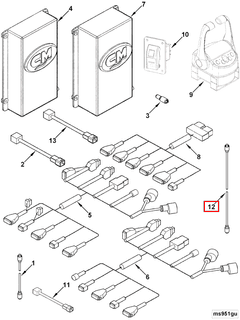

The Cummins 4946020 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a central part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems in commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by connecting components such as lights, sensors, and control units to the power source and each other 1.

Role of the 4946020 Wiring Harness in Truck Operation

The Cummins 4946020 Wiring Harness is integral to the electrical system of a commercial truck. It provides the necessary connections for the engine control module (ECM), sensors, and other electrical components. By facilitating the transmission of power and signals, the wiring harness enables the ECM to monitor and control engine functions, ensuring optimal performance. It also interacts with lighting systems, diagnostic tools, and other electrical accessories, playing a role in their operation 2.

Key Features

The Cummins 4946020 Wiring Harness is characterized by its robust design and high-quality materials. It is engineered to withstand the demanding conditions of commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness features durable connectors and protective coatings that enhance its performance and longevity. Its design also allows for easy integration with other components, simplifying installation and maintenance processes 3.

Benefits of Using the 4946020 Wiring Harness

Utilizing the Cummins 4946020 Wiring Harness offers several advantages in truck operations. It contributes to improved reliability by ensuring stable and efficient electrical connections. This results in enhanced vehicle performance and reduced downtime. Additionally, the harness’s design supports efficient signal transmission, which is vital for accurate engine control and diagnostics. Safety is also improved, as the harness helps prevent electrical faults that could lead to accidents 4.

Installation Considerations

Proper installation of the Cummins 4946020 Wiring Harness is crucial for its effective operation. It is recommended to follow the manufacturer’s guidelines for installation, which may include specific routing paths and securement methods to protect the harness from damage. Special tools or equipment may be required to ensure a secure and proper fit. It is also important to verify that all connections are correctly made to avoid electrical issues 5.

Troubleshooting Common Issues

Common problems with wiring harnesses can include loose connections, damaged wires, or faulty connectors. To troubleshoot these issues, it is advisable to conduct a visual inspection of the harness for any signs of wear or damage. Testing the electrical connections with a multimeter can help identify faulty components. Addressing these issues promptly can prevent more significant electrical problems and ensure the continued reliable operation of the truck 6.

Maintenance Tips

Routine maintenance of the Cummins 4946020 Wiring Harness is important for its longevity and optimal performance. This includes regular inspections for signs of wear, corrosion, or damage. Cleaning the harness and its connections can also help prevent issues related to dirt or moisture buildup. Additionally, ensuring that all connections are tight and secure can contribute to the efficient operation of the electrical system 7.

Safety Precautions

When working with electrical components like the Cummins 4946020 Wiring Harness, it is important to observe safety measures to prevent accidents. This includes disconnecting the battery before beginning any work to avoid the risk of electrical shock. Using insulated tools and wearing protective gear can also enhance safety. It is crucial to follow all safety guidelines provided by the manufacturer to ensure personal safety and the proper functioning of the electrical system 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines, powertrain solutions, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators.

Compatibility with Engine Models

The Cummins Wiring Harness 4946020 is designed to integrate seamlessly with several of Cummins’ engine models, ensuring reliable and efficient electrical connections. This wiring harness is compatible with the following engines:

QSB5.9 CM850 and QSB6.7 M CM2250

The QSB5.9 CM850 and QSB6.7 M CM2250 engines are part of Cummins’ QSB series, known for their robust performance in various applications, from agricultural to industrial use. The Wiring Harness 4946020 is engineered to fit these engines, providing a secure and durable connection that supports the electrical needs of these models.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine, another member of the Cummins QSC series, is designed for heavy-duty applications. The Wiring Harness 4946020 is compatible with this engine, ensuring that the electrical system functions optimally under demanding conditions.

QSM11 CM570

The QSM11 CM570 engine is part of Cummins’ QSM series, which is tailored for marine applications. The Wiring Harness 4946020 is specifically designed to fit this engine, providing a reliable electrical connection that is essential for the marine environment’s unique challenges.

By ensuring compatibility with these engines, the Wiring Harness 4946020 plays a crucial role in maintaining the operational integrity of Cummins’ diverse engine lineup.

Role of Part 4946020 Wiring Harness in Engine Systems

The 4946020 Wiring Harness is an integral component in the orchestration of various engine systems, facilitating seamless communication and operation between different parts.

Integration with Control Systems

In modern engine systems, the control unit is the brain that manages operations. The 4946020 Wiring Harness acts as the nervous system, transmitting signals from the control unit to various actuators and sensors. This ensures that the control unit can effectively monitor and adjust engine performance in real-time.

Interaction with Electrical Throttle Lever

The Electrical Throttle Lever (ETL) is a pivotal component in fuel management and engine performance. The 4946020 Wiring Harness connects the ETL to the control unit, allowing for precise modulation of the throttle based on driving conditions and inputs from the control system. This connection ensures that the throttle responds accurately to driver commands, optimizing fuel efficiency and engine performance.

Enhanced System Coordination

By linking the control unit and the ETL, the 4946020 Wiring Harness enhances the coordination between these components. This results in a more responsive and efficient engine system, capable of adapting to varying driving conditions with minimal delay. The harness ensures that all signals are transmitted swiftly and accurately, maintaining the integrity of the engine’s operation.

Conclusion

The Cummins 4946020 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring reliable and efficient operation of various engine systems. Its robust design, compatibility with multiple engine models, and integration with control systems make it an essential part for maintaining vehicle performance and safety.

-

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5677073.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5677073.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5677073.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5677073.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5677073.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.