This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4951862 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, ensuring that power and signals reach their intended destinations efficiently and safely 1.

Role of the 4951862 Wiring Harness in Truck Operation

The Cummins 4951862 Wiring Harness is integral to the operation of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, to the truck’s power source. This harness facilitates the transmission of electrical signals and power, enabling the operation of critical systems including engine management, lighting, and diagnostic systems. Its integration with other systems ensures that electrical components function correctly, contributing to the truck’s overall performance and reliability 2.

Key Features

The Cummins 4951862 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed to withstand the harsh conditions often encountered in commercial truck operations, including vibrations, temperature extremes, and exposure to chemicals. The harness features durable connectors and terminals, ensuring secure and reliable connections. Additionally, it may include unique characteristics such as enhanced shielding to protect against electromagnetic interference and specialized routing to accommodate the complex layout of commercial truck electrical systems 3.

Benefits of Using the 4951862 Wiring Harness

Utilizing the Cummins 4951862 Wiring Harness offers several advantages. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted with minimal loss. The harness enhances reliability by providing secure and durable connections, reducing the likelihood of electrical failures. Additionally, it plays a role in safety by ensuring that electrical systems operate correctly, which is vital for the safe operation of commercial trucks.

Installation Process

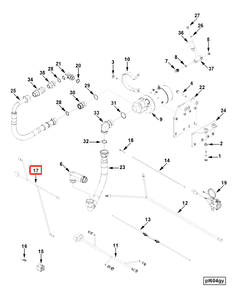

Installing the Cummins 4951862 Wiring Harness involves several steps. First, the existing wiring harness, if present, should be carefully removed. Next, the new harness should be routed according to the manufacturer’s instructions, ensuring that it follows the designated path to avoid interference with other components. Connections should be made securely, using the provided connectors and terminals. Finally, the harness should be tested to ensure that all electrical systems are functioning correctly. Important considerations include ensuring that all connections are secure and that the harness is properly protected from physical damage and environmental factors.

Maintenance and Troubleshooting

Maintaining the Cummins 4951862 Wiring Harness involves regular inspection for signs of wear, damage, or corrosion. Connections should be checked to ensure they remain secure and free from oxidation. In the event of electrical issues, troubleshooting should begin with a visual inspection of the harness and connections. Common issues may include loose connections, damaged wires, or faulty connectors. Addressing these issues promptly can help prevent more significant electrical problems and ensure the continued reliable operation of the truck’s electrical systems.

Safety Considerations

When working with the Cummins 4951862 Wiring Harness, it is important to follow electrical safety practices. This includes ensuring that the truck’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Additionally, tools and equipment used should be insulated to protect against electrical hazards. Workers should be trained in safe electrical practices and aware of the potential risks associated with working on vehicle electrical systems.

Environmental Impact

The production, use, and disposal of the Cummins 4951862 Wiring Harness have environmental considerations. Manufacturing processes should aim to minimize waste and energy consumption. The use of recyclable materials in the harness’s construction can contribute to reducing its environmental impact. Proper disposal practices, including recycling where possible, are important to minimize the environmental footprint of the harness at the end of its life cycle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the automotive industry. The company is known for its high-quality products and commitment to customer satisfaction, playing a significant role in the development and advancement of engine and power technologies.

Cummins Wiring Harness 4951862 Compatibility with Engine Models

The Cummins Wiring Harness part number 4951862 is designed to integrate seamlessly with a variety of Cummins engine models. Below is a detailed description of its compatibility across different engine series:

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 MCRS

- QSK60 CM500

- QSK60 CM850 MCRS

The QSK38 series engines, including the CM2150, CM850, CM500, and CM850 MCRS variants, are compatible with the Wiring Harness 4951862. This harness is engineered to handle the electrical demands of these engines, ensuring reliable power distribution and control.

QSK50 Series

- QSK50 CM2350 K108

The QSK50 CM2350 K108 engine is also compatible with the Wiring Harness 4951862. This model benefits from the harness’s robust design, which supports the increased electrical requirements of the QSK50 series.

QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The QSK95 series engines, specifically the CM2350 K111 and K113 variants, are designed to work with the Wiring Harness 4951862. This compatibility ensures that the harness can manage the higher power output and complex electrical systems of these engines.

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

The QST30 series engines, including the CM2350 T101 and CM552 models, are also compatible with the Wiring Harness 4951862. This harness provides the necessary electrical connections to support the operational needs of these engines.

Conclusion

The Cummins Wiring Harness 4951862 is a versatile component that fits a wide range of Cummins engine models. Its compatibility with the QSK38, QSK50, QSK95, and QST30 series engines ensures that it can meet the diverse electrical requirements of these engines, providing reliable performance and integration. The harness plays a crucial role in the electrical connectivity of various engine systems, facilitating seamless operation and communication among them. Its integration with electrical set accessories, engine lubricating primer, engine oil primer plumbing, and starting motor ensures that these systems function correctly, contributing to the overall performance, reliability, and safety of commercial trucks.

-

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.